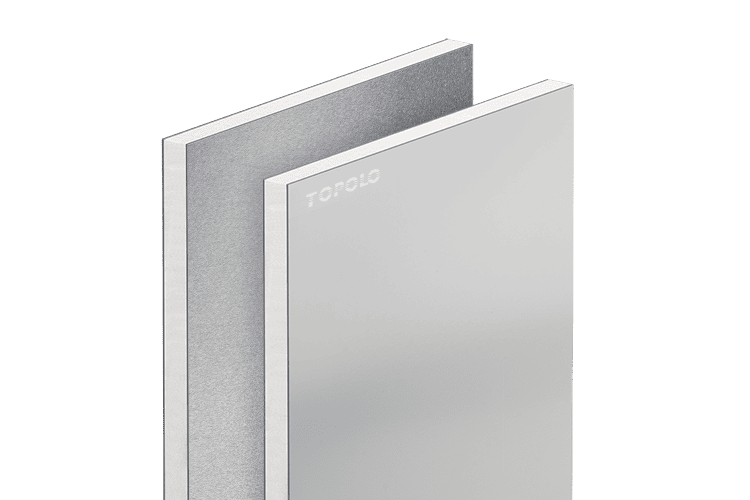

PET Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels

Lightweight, Durable, Eco-friendly

PET foam sandwich panels are a new type of foam composite panel. Compared with other common foam sandwich panels (such as polystyrene (EPS) and polyurethane (PU) foam panels), it not only performs well in performance, but also has significant environmental protection and recyclability advantages. Therefore, it has been widely used in many industries. It is made of polyethylene terephthalate (PET) foam as the core material, combined with different types of skin materials (such as metal, fiber reinforced plastic, aluminum foil, wood, etc.) to form a lightweight, high-strength, excellent thermal insulation and sound insulation composite panel.

TOPOLOGROUP – Innovative Sandwich Panel Manufacturer

TOPOLOGROUP is a leading PET foam sandwich panel manufacturer in China, focusing on the research, development, production and sales of high-performance composite materials. As a technology-driven company, TOPOLOGROUP uses advanced production processes and equipment to provide a variety of PET foam sandwich panels of different specifications and application scenarios to meet the needs of different industries for lightweight, high-strength and environmentally friendly materials.

Gallery

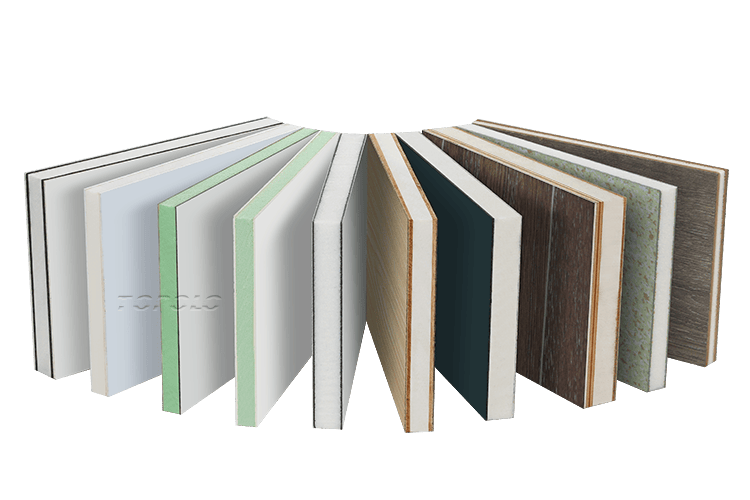

Specifications

| Standard Structure | Inner facing + PET foam core + Outer facing. |

| Facing | FRP/GRP (Glass Fiber Reinforced Plastic) sheet. |

| CFRT (Continuous fiber reinforced thermoplastic). | |

| Aluminum sheet. | |

| Coated steel sheet. | |

| Wood (plywood, MDF). | |

| PVC (Polyvinyl Chloride) Plastic. | |

| PET (Polyethylene Terephthalate) Plastic. | |

| Core | PET (Polyethylene terephthalate) foam. (Density: 60-300kg/m³) |

| Composite Method | Adhesive Bonding or Thermal Composite. |

| Thickness | 10-150mm. |

| Length | ≤12000mm. |

| Width | ≤3200mm. |

Structural Diagram

As a composite material that is both lightweight and high-performance, the classic three-layer structure (facing – core – facing) of PET sandwich panels is the core design to achieve structural stability and functional diversity. This composite form seems simple, but through the synergy of each layer of material, it achieves an efficient balance in mechanical properties, lightweight and application adaptability.

Understand Common PET Foam Sandwich Panels

Common Applications of PET Foam Sandwich Panels

- Box truck bodies made of fiberglass facing PET sandwich panels are light, strong and durable.

- In buses, subways, high-speed trains and other means of transportation, fiberglass facing PET foam sandwich panels are used in floors and other parts to reduce the weight of the vehicle.

- Fiberglass facing PET sandwich panels are used as wall panels, and Plywood facing PET sandwich panels are used as floors.

- PVC/PET facing PET foam sandwich panels are used in the production of modular furniture (such as partitions, bookcases, desktops, bed frames, cabinets, bathroom wall panels, etc.).

PET Foam Core

01. Closed-cell structure

The structural characteristic of PET (polyethylene terephthalate) foam is that the bubbles inside the foam are closed and not connected to the outside world. This special structure gives PET foam the following unique advantages:

- Low water absorption: Since the bubbles are closed, water cannot enter the foam, making it extremely low in water absorption and able to be used stably for a long time in a humid or underwater environment.

- High mechanical strength: The closed bubbles provide strong structural support, making the closed-cell PET foam show higher compressive strength and bending resistance when subjected to external forces.

02. Can be recycled multiple times

- PET foam has significant advantages in environmental protection. After steps such as crushing, cleaning, drying, and melt granulation, the generated PET particles can be used to produce new PET foam or other PET products.

03. Performance parameter of PET foam

| Test items | Standard | unit | Value | TS80 | TS100 | TS120 | TS150 | TS200 | TS50 |

| Density | ISO845 | kg/m³ | Range | 85-95 | 100-110 | 120-130 | 150-160 | 190-210 | 235-260 |

| Compression strength | ISO844 | MPa | AVG | 0.85 | 1.20 | 1.80 | 2.40 | 3.90 | 5.20 |

| Compression modulus | ISO844 | MPa | AVG | 73 | 100 | 115 | 140 | 200 | 235 |

| Tensile strength | ASTM C297 | MPa | AVG | 1.40 | 1.80 | 2.20 | 2.50 | 3.20 | 4.00 |

| Tensile modulus | ASTM C297 | MPa | AVG | 90 | 110 | 120 | 160 | 210 | 275 |

| Shear Strength | ISO1922-2012 | MPa | AVG | 0.55 | 0.80 | 0.90 | 1.25 | 1.70 | 2.05 |

| Shear modulus | ISO1922-2012 | MPa | AVG | 13.5 | 23.0 | 27.0 | 35.0 | 51.0 | 70.0 |

| Roller peeling | ASTM D1781 | mm.N/m | AVG | 20 | 20 | 20 | 20 | 20 | 20 |

Performance Comparison of Different Facing

| Skin Material | FRP/CFRT | Aluminum | Prepainted Steel | Plywood | PVC/PET |

| Weight | Lightweight | Lightweight | Lightweight | Moderate to Heavy | Moderate to Heavy |

| Strength | High strength and impact resistance | High strength and stiffness | High strength and stiffness | Moderate strength | Moderate strength |

| Durability | Excellent resistance to corrosion and environmental factors | Excellent durability, resistant to weather and corrosion | Good durability, resistant to corrosion and UV | Moderate durability, susceptible to moisture | Moderate durability, but resistant to moisture |

| Thermal Insulation | Good insulation properties | Good insulation properties | Poor insulation properties | Moderate insulation properties | Good insulation properties |

| Moisture Resistance | Excellent (resistant to water and moisture) | Excellent (waterproof) | Moderate moisture resistance | Poor (susceptible to swelling and rot in humid environments) | Good (moisture-resistant, but not waterproof) |

| Corrosion Resistance | Very High (corrosion-resistant) | Very High (resistant to corrosion) | High (corrosion-resistant with coating) | Low (wood can rot, susceptible to pests) | Moderate (resistant to many chemicals, but not UV stable) |

| Cost | Medium to High | High | Medium | Medium | Medium |

| UV Resistance | High | Moderate | Moderate to High | Low | Low |

| Flexibility | Moderate | Low | Low | High | Moderate to High |

| Fire Resistance | Good | Moderate | Moderate | Poor | Moderate |

| Aesthetic Quality | Glossy, smooth finish | Smooth, metallic finish | Smooth, customizable finish (variety of colors and designs) | Natural, wood-like finish | Smooth, glossy, and customizable in colors |

If you are looking to carry out your project with PET foam composite materials, please contact us and we will provide you with high-level solutions.