FRP Skin PET Foam Sandwich Panels

Lightweight composite panels

Home » Materials » Foam Sandwich Panels » PET Foam Sandwich Panels

PET (polyethylene terephthalate) foam is recognized as one of the most promising new foam core materials for current and future development due to its environmental friendliness and sustainability. As an alternative to wood and metal, FRP skin PET foam sandwich panels have become the preferred material for lightweighting in many industries while maintaining excellent performance and economic benefits.

Main Features

Lightweight & Thin

Because PET foam is generally hard, panels made from it can be as thin as 10mm or less, reducing overall weight without sacrificing strength.

Structural Strength

The FRP layer offers excellent rigidity and durability. Combined with the rigidity of the PET foam core, the composite panel boasts structural strength comparable to or exceeding that of wood panels of similar area and weight.

Environmental Adaptability

The gel coat on the FRP sheet completely isolates moisture, while the closed-cell PET foam absorbs virtually no water. This purely inorganic material eliminates problems such as mold and rot. FRP skin PET foam sandwich panels are suitable for use in rainy, salty climates and spaces exposed to corrosive chemicals.

Low maintenance for easy cleaning

The surface of FRP is smooth and non-porous, and stains (such as dust, oil, and fingerprints) are difficult to penetrate and adhere. Ordinary dust can be rinsed with clean water or wiped with a wet cloth. Stubborn stains can be quickly removed by rubbing with a neutral detergent.

Easy to Machining

It has the same easy-to-cut properties as wood and can be processed using both manual cutting tools and CNC machines.

Specifications

| Facing | Gelcoat FRP(GRP) sheet. (Thickness: 0.7-5.0mm) |

| Surface Color | RAL color series |

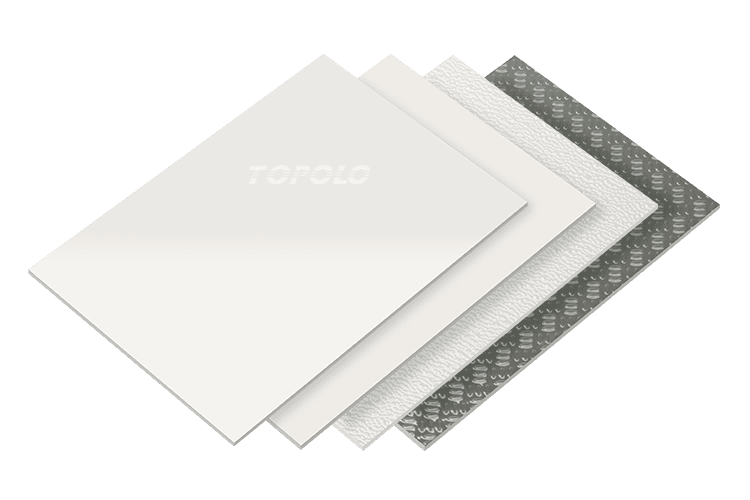

| Surface Treatment | Glossy, matte, embossed, rough, etc. |

| Core | PET (Polyethylene terephthalate) foam. (Density: 60-300kg/m³) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Thickness | 10-150mm. |

| Length | ≤12000mm. |

| Width | ≤3200mm. |

| Working Temperature | -40℃ to +80℃ |

Structural Diagram

- Due to the high hardness and flexural strength of PET foam, internal reinforcement is generally not required. Therefore, PET foam sandwich panels typically adopt a typical sandwich structure: skin + core + skin.

- To enhance compressive and impact resistance, a composite energy-absorbing layer is often added between the FRP skin and the PET foam core.

Details

FRP Facing

The smooth FRP panel is a high-strength material made of glass fiber and resin matrix through a composite process. It has excellent characteristics such as lightweight, high strength, corrosion resistance and aging resistance. FRP panels are available in a variety of surface colors and patterns to suit different application requirements.

PET Foam Core

We provide both virgin and recycled PET foam cores depending on application requirements.

- Density: 60-300kg/m³.

- Compression strength: 0.85-5.20MPa.

- Compression modulus: 73-235MPa.

- Tensile strength: 1.40-4.00MPa.

- Tensile modulus: 90-275MPa.

- Shear Strength: 0.55-2.05MPa.

- Shear modulus: 13.5-70.0 MPa.

- Roller peeling: 20mm.N/m.

Applications

FRP skin PET foam sandwich panels are widely used as wall panels, floors, partitions, roof panels, etc. in various industries. Common applications include:

Camper RV bodies

- Truck campers

- Caravans

- Teardrop trailers

- Off-road trailers

- Adventure trucks, etc.

Truck & Trailer Bodies

- Dry cargo trucks.

- Moving trucks.

- Portable trailers.

- Food trailers, etc.

Rail Transit Flooring

- High-speed rail.

- Subway.

- Tram.

- Bus, etc.

Furniture

- Cabinets.

- Tabletops.

- Door panels.

- Bedboards, etc.

Production and Processing

TOPOLOGROUP is a professional manufacturer of FRP skin PET foam sandwich panels. Panel sizes, thicknesses, and colors are customizable. Panel sizes up to 12 meters x 3.2 meters are available.

- The premium UV-resistant FRP panels offer a service life of over ten years and maintain their vibrant color.

- We insist on sustainable development and product quality improvement. A large amount of recycled PET foam core is used in the production of sandwich panels, and its quality is the same as that of virgin PET foam core.

- Sandwich panels are laminated under high pressure in a vacuum environment. The resulting composite panel has a smooth surface and a tight bond between the skin and core

- The pressed PET foam sandwich panels can be processed into any custom design on a CNC machining platform, maintaining consistent product precision.

We also offer FRP sandwich panels with XPS (polyethylene terephthalate), PU (polyurethane), and PVC (polyvinyl chloride) foam cores. Please contact us for more information.