Coated Steel Skin PET Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels » PET Foam Sandwich Panels

☑ Lightweight and High Strength

☑ Corrosion and Moisture Resistance

☑ Environmentally Friendly and Recyclable

Coated steel-coated PET foam sandwich panels are an economical composite material that combines lightweight and high strength. Made from double-coated steel sheets (GI, GL, PPGI, PPGL, etc.) bonded to a PET foam core, they offer excellent structural stability and weather resistance.

Typical Features

☑ Lightweight and High Strength

The panel uses high-performance PET foam as the core material, featuring low density and high structural strength. It significantly reduces overall weight while maintaining excellent compressive and flexural strength. This makes it an ideal solution for achieving a perfect balance between lightness and load-bearing capacity in transportation vehicles, building enclosures, and marine components.

☑ Corrosion and Moisture Resistance

Both sides are coated with galvanized steel sheets treated with an anti-corrosion coating, providing outstanding resistance to oxidation, moisture, water, and chemical corrosion. Whether in high-humidity environments, marine climates, or outdoor exposure conditions, the panel ensures long-term durability and stability.

☑ Environmentally Friendly and Recyclable

The core layer is made of renewable PET foam, which is eco-friendly and fully recyclable. During production and use, the product aligns with sustainable development principles, helping users reduce carbon emissions and achieve greener structural solutions.

Typical Applications

Vehicle Industry: Used as wall panels for trailers and truck bodies.

Architectural Industry: Used as wall panels, partitions, or interior trim panels for modular buildings.

Specifications

| Skin | GI (Galvanized steel) sheet. GL (Galvalume steel) sheet. PPGI (Pre-painted Galvanized) steel sheet. PPGL (Pre-painted Galvalume) steel sheet. |

| Core | PET (Polyethylene terephthalate) foam. (Density: 60-300kg/m³) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Thickness | 10-150mm. |

| Length | ≤12000mm. |

| Width | ≤1500mm. |

Performance Parameters

| Thickness | 0.2mm – 6.0mm |

| Width | 600mm – 1500mm |

| Zinc Coating Weight | Z40, Z60, Z80, Z100, Z120, Z180, Z275 |

| Spangle Types | Normal Spangle; Minimized Spangle; No Spangle |

| Tensile Strength | 270-500 MPa |

| Yield Strength | 140-360 MPa |

| Surface Coating | Polyester (PE), polyvinylidene fluoride (PVDF) |

| Color | RAL color series |

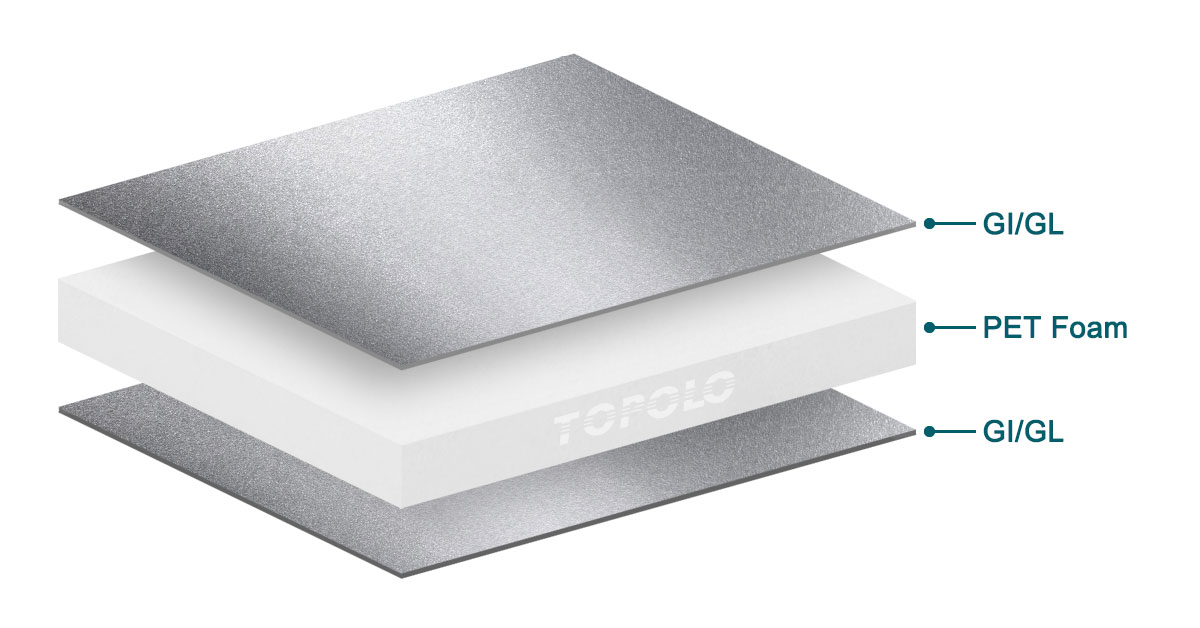

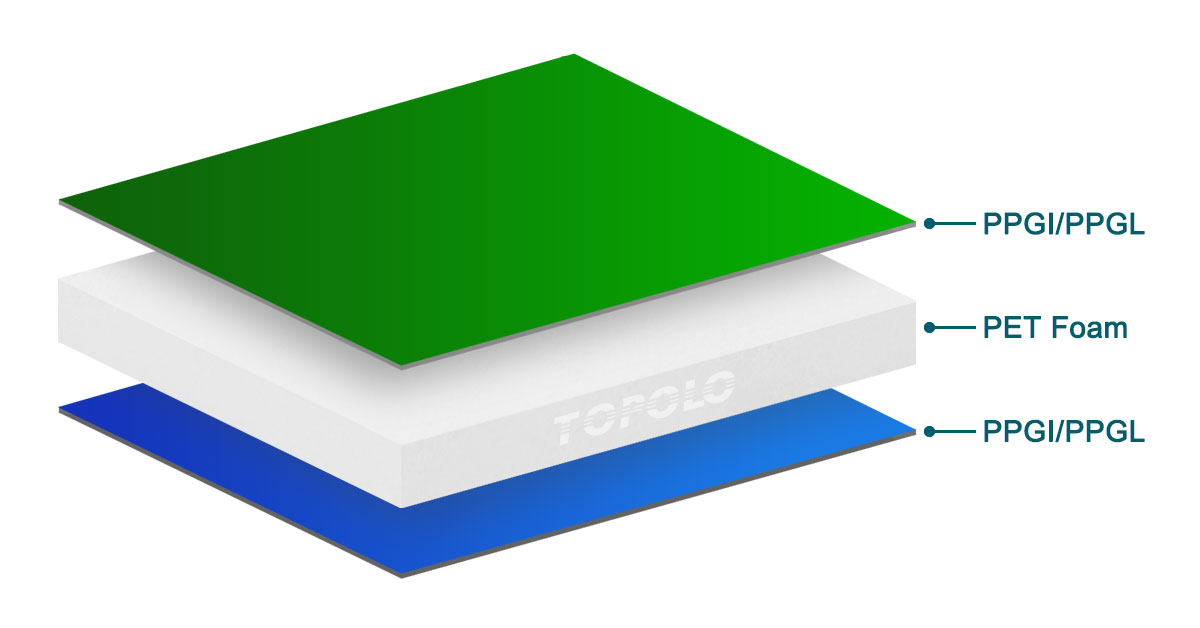

Structural Diagram

Galvanized steel skin sandwich panels

Pre-painted steel skin sandwich panels

Coated steel types

- GI, GL sheet

Galvanized steel is renowned for its exceptional corrosion resistance and durability. It’s a process in which hot-rolled or cold-rolled steel is coated with a layer of zinc or aluminum-zinc to protect it from rust. This coating is typically applied through a process called hot-dip galvanizing, where the steel is immersed in molten zinc or a mixture of aluminum and zinc. Steel coated with a mixture of zinc (Zn) and aluminum (Al), known as galvalume steel, offers superior corrosion resistance compared to traditional galvanized steel, especially under high temperatures and harsh environmental conditions.

Performance Parameters

| Thickness | 0.2mm – 6.0mm |

| Width | 600mm – 1500mm |

| Zinc Coating Weight | Z40, Z60, Z80, Z100, Z120, Z180, Z275 |

| Spangle Types | Normal Spangle; Minimized Spangle; No Spangle |

| Tensile Strength | 270-500 MPa |

| Yield Strength | 140-360 MPa |

- PPGI, PPGL sheet

PPGI (pre-painted galvanized steel) or PPGL (pre-painted galvanized steel) is a GI or GL steel sheet that has been pre-treated and then coated with one or more layers of organic paint, which is then baked and cured. This improves the aesthetics and weather resistance of the GI or GL steel sheet. This ensures the sheets can withstand harsh environmental conditions, including moisture, UV radiation and physical wear and tear.

PET Foam Core

The structural characteristic of PET (polyethylene terephthalate) foam is that the bubbles inside the foam are closed and not connected to the outside world. This special structure gives PET foam the following unique advantages:

- Low water absorption: Since the bubbles are closed, water cannot enter the foam, making it extremely low in water absorption and able to be used stably for a long time in a humid or underwater environment.

- High mechanical strength: The closed bubbles provide strong structural support, making the closed-cell PET foam show higher compressive strength and bending resistance when subjected to external forces.

Performance parameters

We provide both virgin and recycled PET foam cores depending on application requirements.

| Test items | Standard | unit | Value | TS80 | TS100 | TS120 | TS150 | TS200 | TS50 |

| Density | ISO845 | kg/m³ | Range | 85-95 | 100-110 | 120-130 | 150-160 | 190-210 | 235-260 |

| Compression strength | ISO844 | MPa | AVG | 0.85 | 1.20 | 1.80 | 2.40 | 3.90 | 5.20 |

| Compression modulus | ISO844 | MPa | AVG | 73 | 100 | 115 | 140 | 200 | 235 |

| Tensile strength | ASTM C297 | MPa | AVG | 1.40 | 1.80 | 2.20 | 2.50 | 3.20 | 4.00 |

| Tensile modulus | ASTM C297 | MPa | AVG | 90 | 110 | 120 | 160 | 210 | 275 |

| Shear Strength | ISO1922-2012 | MPa | AVG | 0.55 | 0.80 | 0.90 | 1.25 | 1.70 | 2.05 |

| Shear modulus | ISO1922-2012 | MPa | AVG | 13.5 | 23.0 | 27.0 | 35.0 | 51.0 | 70.0 |

| Roller peeling | ASTM D1781 | mm.N/m | AVG | 20 | 20 | 20 | 20 | 20 | 20 |