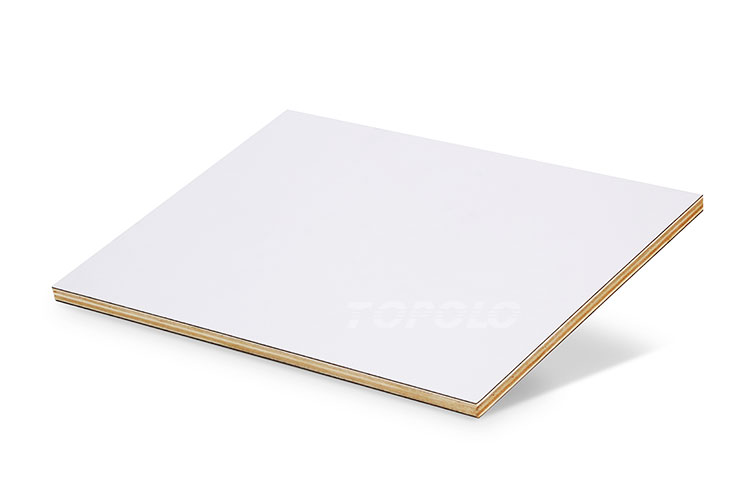

GRP/FRP Plywood Panels

Marine grade fiberglass reinforced plywood

GRP/FRP plywood panels are composite materials that combine FRP (fiberglass reinforced plastic or GRP) with plywood. The sandwich panels are known for their strength, durability, cost-effectiveness, and environmental friendliness, making them an ideal choice for various applications.

Product Advantages

High Strength

FRP plywood panels offer excellent compression and bending resistance. They are not easily deformed under external forces, providing additional structural support, making them suitable for applications that require heavy load-bearing.

Durability

Enhanced by FRP, the panels offer superior corrosion resistance and UV protection, allowing them to be used for extended periods in harsh environments. They are especially suitable for areas with high humidity and intense UV exposure.

Cost-Effective

Compared to other high-strength materials, FRP plywood panels offer significant cost advantages. With mature production processes, they provide more efficient material utilization, making them a great option for projects with limited budgets but high-performance requirements.

Environmental protection

Plywood is a renewable resource. Compared with traditional wood, plywood has higher production efficiency and can make full use of wood resources, thus reducing waste.

Innovative FRP Sandwich Panel Manufacturer

TOPOLOGROUP is an FRP plywood panel manufacturer in China. We provide a variety of customized sandwich panel services. Our factory is equipped with industry-leading composite panel production lines, using unique production processes to meet users’ personalized design requirements.

- One-piece vacuum composite process: The sandwich panel is laminated under high pressure in a vacuum environment. The surface of the panel after molding is flat, and tightly bonded, and the strength is far superior to ordinary composite panels.

- Extraordinary size customization: The size of the composite panel can reach 12mx3.2m. (The current maximum size of the container is 40 feet (12.03 meters)

- Any shape can be processed: High-precision CNC processing can meet any personalized design needs and maintain the consistency of product precision.

Specifications

| Facing | Flat FRP sheet. (Thickness: 0.7-5.0mm) |

| Surface Treatment | Glossy, matte. |

| Surface Color | RAL series. |

| Core | Plywood. (Birch, pine, poplar, eucalyptus, oak, etc.) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Total Thickness | 10-50mm. |

| Length | ≤12000mm. |

| Width | ≤3200mm. |

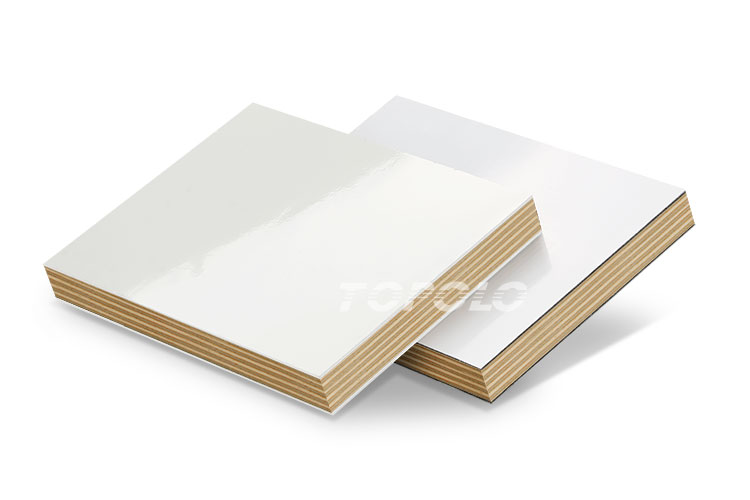

Structural Diagram

FRP plywood panels are typical 3-layer sandwich panels with a middle layer of plywood and two outer layers of FRP sheets bonded together with adhesive.

Flat FRP Facing

The outer layers of the sandwich panel are made of GRP/FRP (fiberglass-reinforced plastic). These FRP skins are lightweight, corrosion-resistant, and highly durable, protecting the plywood core from moisture, chemicals, and physical damage. Our FRP surface is treated with a UV-resistant gel coat for excellent weather resistance.

Common Performance Parameters of FRP sheets

| Thickness | 1.0mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm |

| Weight(Kg/m2) | 1.5 | 2.25 | 3 | 3.75 | 4.5 |

| Glass content(%) | 19 | 25 | 29 | 30 | 30 |

| Tensile strength(Mpa) | 60 | 80 | 92 | 95 | 97 |

| Elongation at break(%) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Elastic modulus(Gpa) | 5.5 | 7 | 7.3 | 7.6 | 7.8 |

| Izod impact strength(KJ/m2) | 45 | 55 | 70 | 80 | 95 |

Waterproof Plywood Core

The core of the sandwich panel is made of plywood, a strong and flexible wood product composed of multiple layers of veneer. Plywood provides the necessary structural integrity and rigidity to the panel. Our plywood is treated to be fire and water resistant and suitable for marine environments.

Standard Thickness (Customizable)

| Thickness | Weight (Tolerance: ±5%) |

| 11 mm | 8.9kg/m² |

| 14 mm | 10.4kg/m² |

| 17 mm | 11.9kg/m² |

| 21 mm | 13.4kg/m² |

| 24 mm | 14.9kg/m² |

Applications

FRP plywood panels are valued for their ability to combine the structural benefits of plywood with the protective and durable properties of FRP, making them suitable for a wide range of demanding applications.

- Truck & Trailer Bodies

FRP plywood panels are commonly used in the construction of dry freight truck bodies, and trailers. Their strength and durability make them ideal for withstanding the rigors of transportation.

- Bus and RV Construction

These panels are used in the walls, floors, and roofs of buses, RVs, and other specialty vehicles due to their lightweight and robust properties.

- Modular Buildings

FRP plywood panels are used in modular building construction, including temporary structures and portable buildings, where quick assembly and durability are crucial.

- Marine Applications

In the marine industry, these panels are used in boat decks, bulkheads, and cabin structures due to their resistance to moisture and corrosion.

- Agricultural Structures

FRP plywood panels are used in farm equipment and storage units due to their durability and ease of maintenance.

New FRP Plywood Panels Offer Improved Performance

Based on extensive application research, TOPOLOGRUP has developed a new thermoplastic FRP to replace traditional thermosetting FRP as a plywood cladding. It offers improved wear and pressure resistance and is recyclable. Learn More