XPS Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels

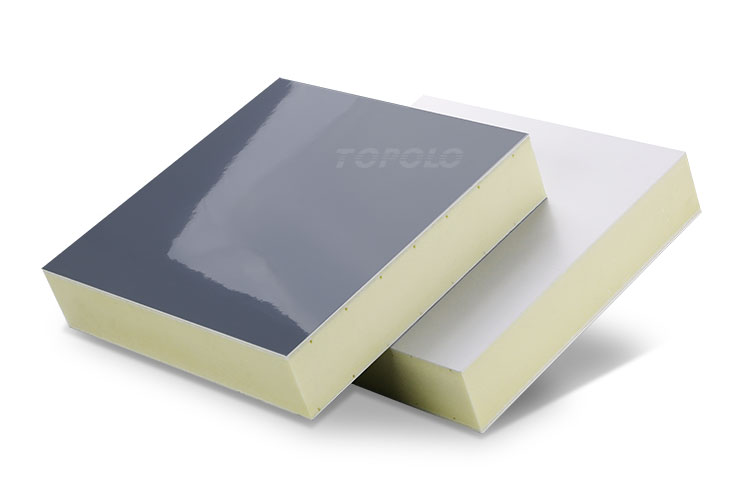

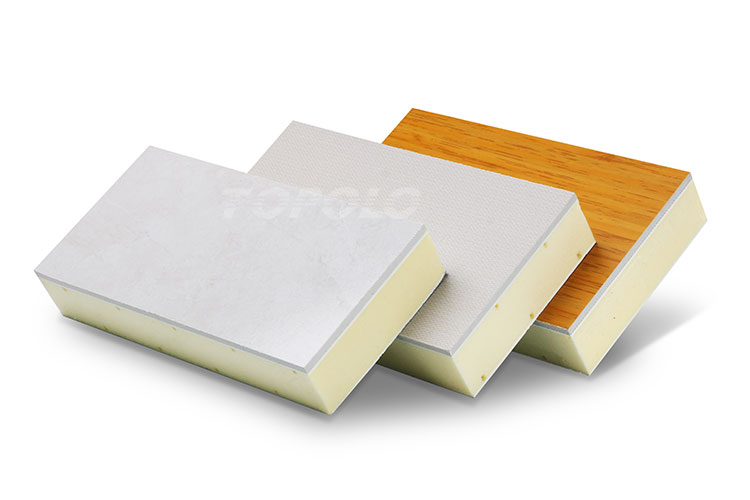

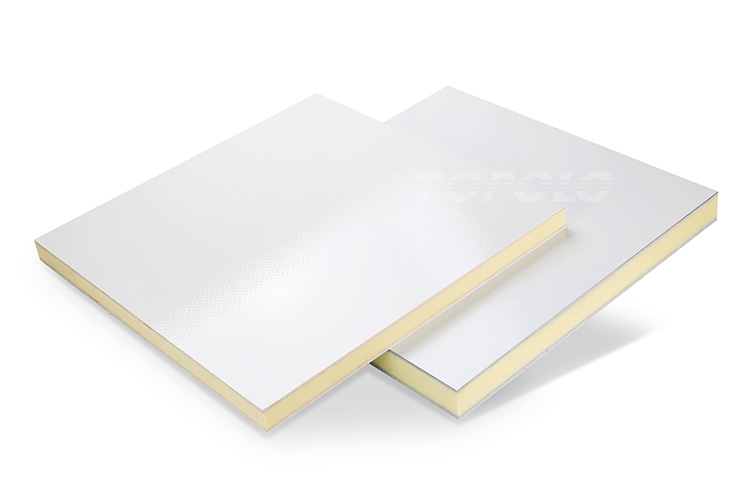

- FRP Skin Series

- CFRT Skin Series

- Aluminum Skin Series

- Steel Skin Series

- Plywood Skin Series

- PET/PVC Skin Series

Reasons for choosing XPS foam as core material

Excellent thermal insulation performance

XPS foam has a very low thermal conductivity, generally between 0.020-0.035 W/(m・K), which can effectively block heat transfer and maintain a stable temperature inside the product.

Extremely lightweight

XPS foam has a low density, usually less than 50kg/m³. Due to its light weight and the thin skin materials, XPS foam sandwich panels are easy to handle, transport and install.

High Compressive Strength

The special closed-cell structure of XPS foam gives it extremely strong compressive strength, generally exceeding 400 kPa. Compared to other brittle foam core composite panels, it can withstand greater loads.

Excellent waterproof and moisture-proof performance

XPS foam has a closed-cell structure, resulting in extremely low water absorption, virtually eliminating any water absorption. Even prolonged immersion in water will not deteriorate or rot. Its stable performance prevents water absorption, which can lead to reduced insulation performance and structural damage to the composite board.

Good fire resistance

By adding flame retardants, XPS foam can achieve a fire resistance rating of B1 (hard to burn), which can slow the spread of fire to a certain extent.

Specifications

| Facing | FRP (Glass Fiber Reinforced Plastic) sheet. |

| CFRT (Continuous fiber reinforced thermoplastic) sheet. | |

| Aluminum sheet. | |

| Galvanized steel sheet. (GI/GL) | |

| Pre-painted steel sheet. (PPGI/PPGL) | |

| Stainless steel sheet. | |

| HPL Plywood. | |

| PVC (Polyvinyl Chloride) plastic sheet. | |

| PET (Polyethylene Terephthalate) plastic sheet. | |

| Core | XPS (Extruded Polystyrene) foam. (Density: 35-50kg/m³) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Thickness | 10-150mm. |

| Length | ≤12000mm. |

| Width | ≤3200mm. |

Comparison of skin materials

The exterior facing of XPS foam sandwich panels can be made from a variety of materials, including metal (steel, aluminum), plywood, FRP (Glass Fiber Reinforced Plastic), CFRT (Continuous fiber reinforced thermoplastic), hard plastic (PET, PVC, etc.), depending on the application and environmental conditions.

| Facing Material | Weight | Strength | Corrosion Resistance | Thermal Conductivity | Fire Resistance | Cost | Ease of Processing |

|---|---|---|---|---|---|---|---|

| FRP sheet | Light | High (depends on fiber type) | Excellent | Low | Moderate | Moderate | Easy |

| CFRT sheet | Very light | Very high (superior to FRP) | Excellent | Low | Moderate | Low | Easy |

| GI/GL/PPGI/PPGL steel sheet | Heavy | Very high | Moderate | High | Excellent | Low | Difficult |

| Stainless steel sheet | Heavy | Very high | Excellent | High | Excellent | High | Difficult |

| Aluminum sheet | Light | Moderate | Excellent | High | High | High | Moderate |

| HPL plywood | Moderate | High (depending on thickness) | Poor | Low | Low | Low | Easy |

| PVC plastic sheet | Light | Moderate | Excellent | Low | Low to moderate | Low | Easy |

| PET plastic sheet | Very light | Moderate | Good | Low | Low | Moderate | Easy |

Understanding common types

How to Improve the Performance of XPS Foam Sandwich Panels

In addition to the selection of high-quality materials and advanced composite technology, the scientific design of TOPOLOGROUP has greatly improved the performance of XPS foam sandwich panels.

- Pre-embed structural materials in XPS foam as a “skeleton” to enhance its structural strength. These materials include glass fiber profiles, waterproof wood, aluminum tubes, sheet metal, etc.

- Add energy-absorbing materials between the foam and the surface to enhance its impact resistance.

- XPS foam can be combined with other materials such as PET foam, PVC foam, plywood, etc. as a core material to improve the performance of sandwich panels.

Applications

XPS foam sandwich panels are used in a variety of industries that require insulation, lightweight construction and durability, including construction, refrigeration, transportation and marine applications.

Vehicle bodies

- Refrigerated trucks.

- Dry cargo trucks.

- Livestock trucks.

- Poultry trucks.

- Ambulances.

- Horse carriages, etc.

- Camping vehicles, etc.

Modular and prefabricated buildings.

- Mobile toilets.

- Capsule rooms.

- Mobile offices.

- Cold storage rooms.

- Clean rooms.

- Greenhouses.

- Animal shelters.

- Industrial equipment enclosures.

- Aquaculture facilities, etc.

Marine

- Yachts.

- Cruise ships.

- Fishing boats.

- Lifeboats, etc.

Furniture

- Cabinets.

- Tabletops.

- Wardrobes.

- Display stands, etc.

Composite Panel Manufacturer in China

TOPOLOGROUP produces a variety of composite panels with XPS foam as the core material. These panels come in a variety of structures and sizes, each with excellent application properties.

- Laser positioning ensures the accuracy of sandwich panels.

- Automatic glue spraying ensures uniform distribution of adhesive.

- Vacuum high-pressure composite ensures the bonding strength of sandwich panels.

- CNC machining completes the processing of complex shapes.

For more information about XPS foam sandwich panels please contact us.