Thermoplastic Composite Honeycomb Panels

Home » Materials » Polypropylene Honeycomb Panels

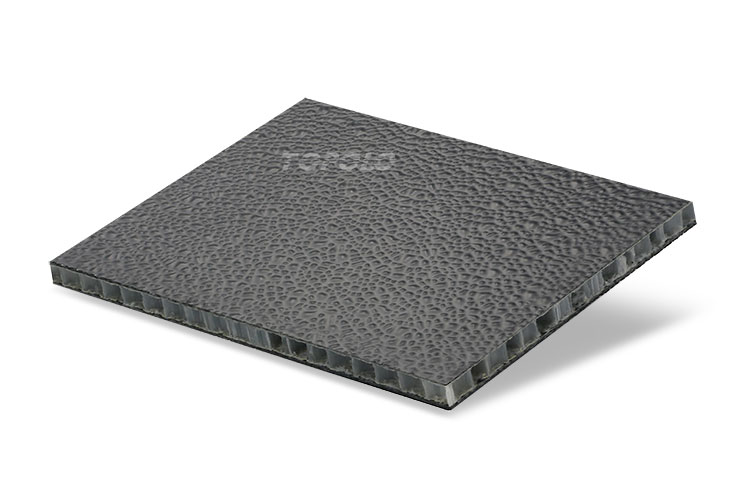

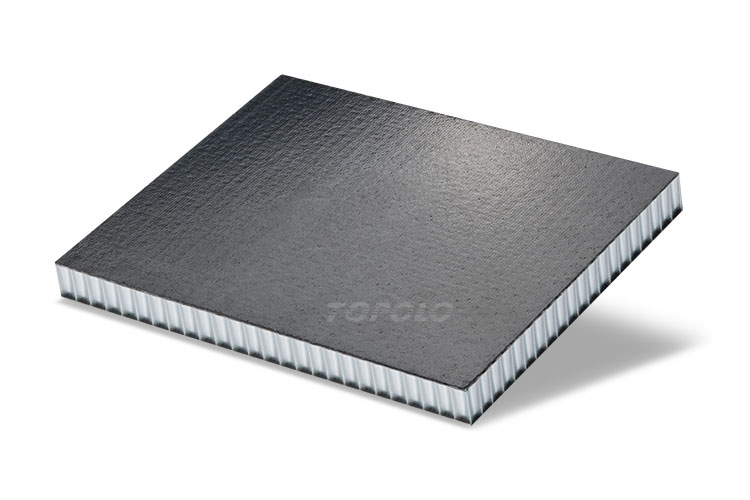

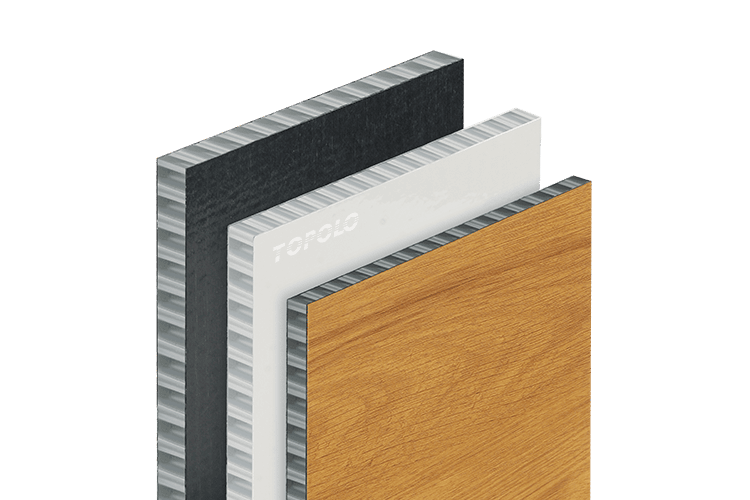

CFRT Skin Polypropylene Honeycomb Core Sandwich Panels

- Lightweight

- High Strength to Weight Ratio

- Impact Resistance

- Chemical Resistance

- 100% Recyclable

Various industries are seeking lighter, more durable composite panels to improve the energy efficiency of their products. Thermoplastic composite polypropylene honeycomb panels are composite materials different from traditional adhesive honeycomb sandwich panels. They are made of CFRT (continuous fiber reinforced thermoplastic) composite sheets and polypropylene (PP) honeycomb cores by thermal composite processing. Because the thermoplastic resin permeates each other during the heating process, the CFRT sheet and the honeycomb core material are more closely composited and difficult to separate after cooling. This kind of bonding strength cannot be achieved by adhesive alone.

Main Characteristics

Lightweight

The honeycomb structure significantly reduces weight.

High Strength to Weight Ratio

The panels can withstand large loads and remain structurally stable.

Impact Resistance

Due to the energy-absorbing properties of the honeycomb core, the panels can release the impact of external forces.

Chemical Resistance

Thermoplastic materials are absolutely waterproof and resistant to a wide range of chemicals, which contributes to the durability of the panels in harsh environments.

100% Recyclable

Since the skin and core materials are thermoplastic, the panels are recyclable.

Specifications

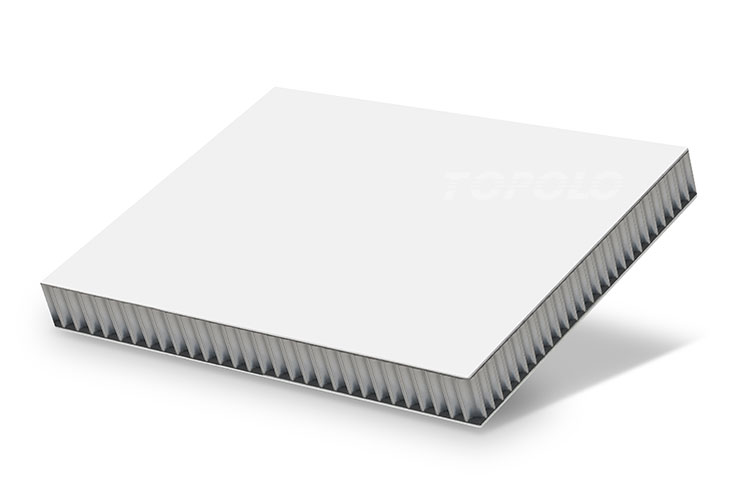

Structural Diagram

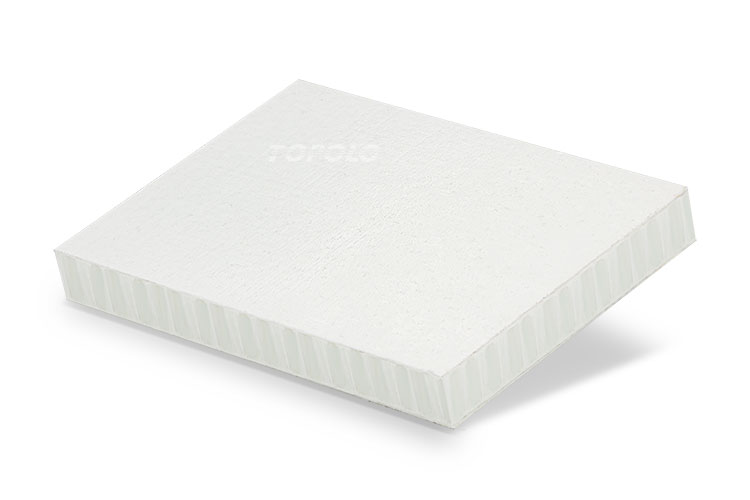

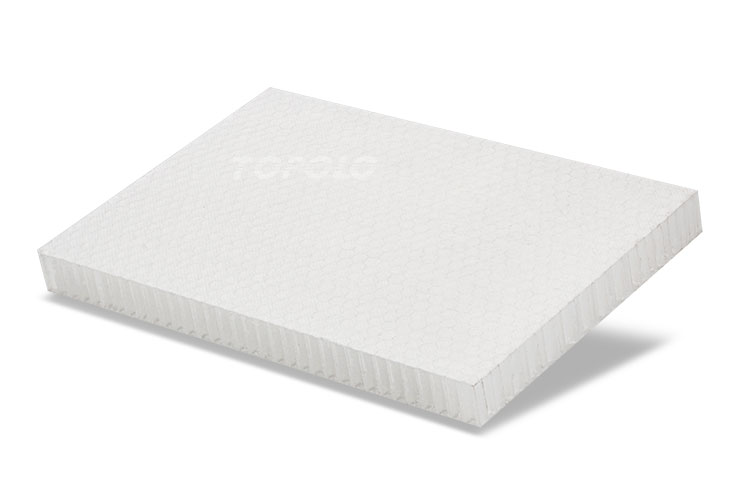

Thermoplastic composite polypropylene honeycomb panels offer a simple structure and superior performance. It is a typical sandwich structure without any internal added materials.

Processing Principle

The honeycomb core is fed into the composite area via conveyor rollers. Continuous CFRT-reinforced skins are simultaneously introduced onto the upper and lower surfaces. After being softened by preheating rollers, they are continuously pressed together by a pair of hot pressing rollers (adjustable temperature and pressure). The high temperature of the hot rollers melts the skin resin, while the pressure bonds the skin to the honeycomb core. The core is then cooled and shaped by cooling rollers, achieving continuous composite.

Durable CFRT Facing

Continuous fibers are combined with thermoplastic resins to create lightweight and durable UD prepreg tapes, which are then thermal laminated together at set angles to form CFRT sheets with improved performance. CFRT laminates are known for their excellent mechanical properties, including high strength-to-weight ratio, good impact resistance, and resistance to environmental factors such as moisture and chemicals.

Common Performance parameters of CFRT sheets

| Resin Type | Thermoplastic Polypropylene |

| Reinforcement Fiber | Continuous Glass Fiber |

| Using Temperature | ≤100°C |

| Fiber Content | 60-75% |

| Density | 1.54-1.63 g/cm³ |

| Thickness (mm) | 0.7-2.0 mm or customized |

| Unidirectional Tape Layers | 2-9 |

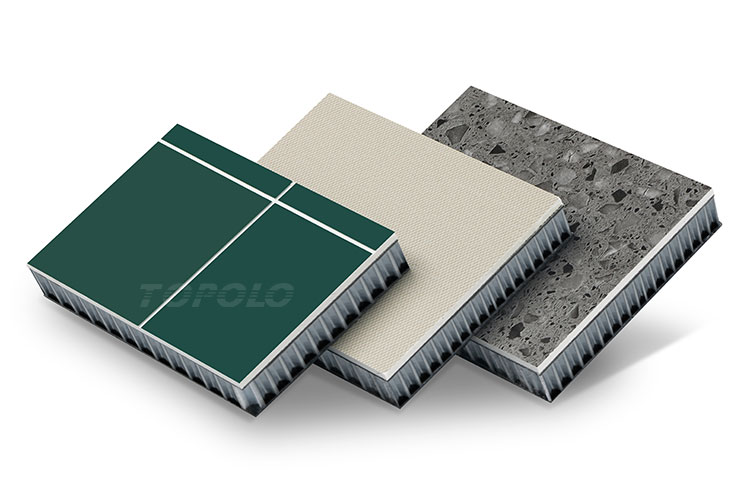

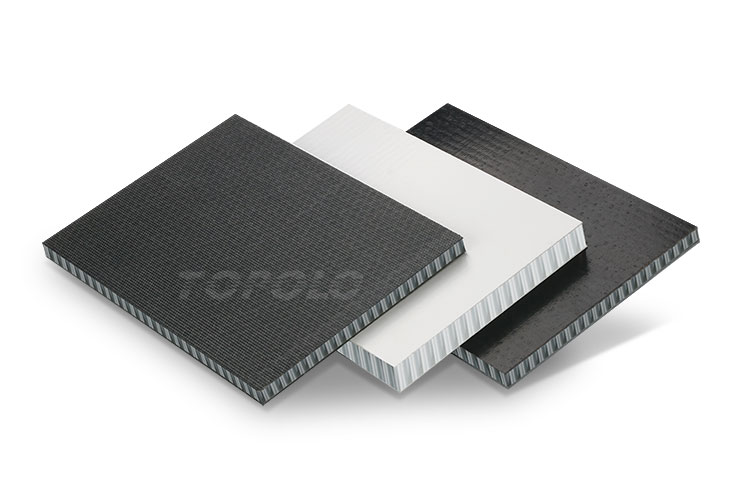

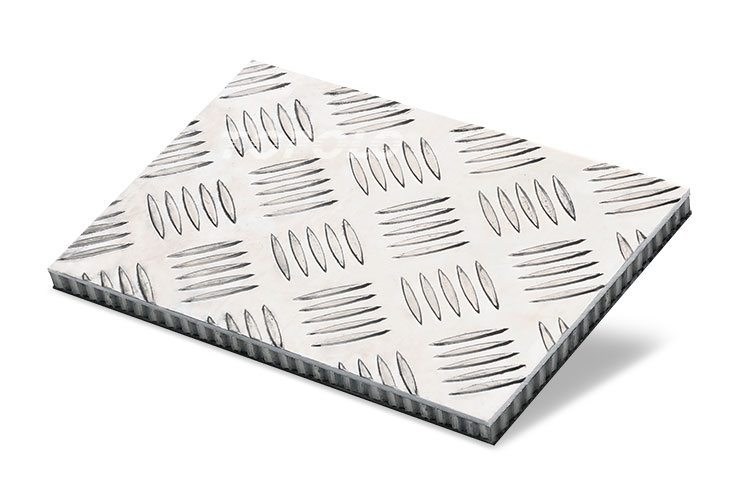

| Laminating Film (Optional) | Polyester Film (Matte/Glossy/Patterned) |

High Modulus Polypropylene Honeycomb

Polypropylene honeycomb is a lightweight, waterproof, strong thermoplastic designed based on the bionic principle of honeycomb. It is ideal for use as the core material in lightweight sandwich panel structures.

Common Performance Parameters of Polypropylene Honeycomb Core

| Cell size(mm) | 8 | 10 | 12 |

| Density(kg/m³) | 80 | 75 | 70 |

| Compressive Strength(MPa) | 1.66 | 1.58 | 1.47 |

| Compressive Modulus(MPa) | 45.7 | 41.2 | 38.9 |

| Shear Modulus(MPa) | 0.50 | 0.45 | 0.40 |

| Operating Temperature(℃) | -40-80 | -40-80 | -40-80 |

| Thermal insulation U value | 2.2 | 2.2 | 2.2 |

Application of Thermoplastic Composite Honeycomb Panels

Our Customized Services

TOPOLOGROUP relies on advanced thermoplastic composite material technology to make the production of polypropylene honeycomb composite panels simpler and more efficient, improve the utilization rate of raw materials and shorten production time.

Tell us about your application requirements and learn more about thermoplastic composite honeycomb panels.