Refrigerated Truck Bodies

Home » Truck & Trailer Solutions » Box Truck Bodies

☑ Modular Design

☑ Composite Materials

☑ CKD/SKD/CBU

TOPOLOGROUP is a new type of box truck body manufacturer in China, committed to providing higher quality, more reliable and more cost-effective solutions for refrigerated truck bodies. Here, we can solve a series of body manufacturing problems for you. We are unique in the Chinese refrigerated truck market, applying the latest technology and materials to body manufacturing. We serve refrigerated truck manufacturers, cold chain companies, food companies, logistics companies, rental companies, etc. all over the world. Our refrigerated truck bodies are delivered to users in the form of CKD (completely knocked down), SKD (semi-knocked down) and CBU (completely assembled).

Applications

Efficiently ensure the safety of cold chain transportation, preventing goods from spoiling, losing their effectiveness, or being damaged by temperature fluctuations.

- Meat.

- Seafood.

- Ice cream.

- Vegetables.

- Fruit.

- Dairy products.

- Baked goods.

- Chocolate.

- Beverages.

- Alcoholic beverages.

- Pharmaceuticals.

- Flowers.

- Chemical products, etc.

Refrigerated Truck Body Dimensions

At TOPOLOGROUP, we offer a wide range of refrigerated box sizes. From compact mini boxes for city delivery, to the popular standard 4.2m boxes, and even super-large boxes for long-haul transportation.

Specifications (Customizable)

| Type | Length (mm) | Width (mm) | Height (mm) | Typical Use |

| Mini | 2500 | 1770 | 1400 | Urban “last mile” delivery. |

| Small | 2900 | 1800 | 1980 | |

| 3200 | 2032 | 1613 | ||

| Small/medium | 3410 | 2000 | 1910 | |

| Standard light-duty | 4200 | 2050 | 2170 | |

| Medium | 4200 | 2200 | 2300 | Regional distribution and medium-volume cold chain. |

| 4250 | 2050 | 1910 | ||

| 4460 | 2170 | 2200 | ||

| 4460 | 2170 | 2200 | ||

| 4500 | 2100 | 2100 | ||

| 4500 | 2200 | 2521 | ||

| Medium/large | 5000 | 2300 | 2350 | |

| 5100 | 2450 | 2335 | ||

| 5803 | 2390 | 2469 | Long-distance trunk transport and large-volume cold chain logistics. | |

| Large | 6720 | 2350 | 2300 | |

| 7000 | 2310 | 2300 | ||

| Heavy-duty | 7920 | 2600 | 2600 | |

| 8650 | 2585 | 2565 | ||

| 8665 | 2600 | 2350 | ||

| 8700 | 2480 | 2400 | ||

| 9600 | 2600 | 2600 |

Benefits of Our Solutions for Refrigerated Truck Bodies

☑ Fashionable and beautiful shape attracts more users to buy and enhances the corporate image.

☑ Modular parts make the body assembly more efficient.

☑ More efficient thermal insulation reduces the cost of truck transportation.

☑ Optimize the internal configuration, improve the structural strength and carrying capacity, and extend the service life of the refrigerated box.

☑ Provide multi-temperature zone box design to meet multiple uses of one box (freezer zones, refrigerated zones, fresh-keeping zones, normal temperature zones).

How We Enhance the Performance of Refrigerated Truck Bodies

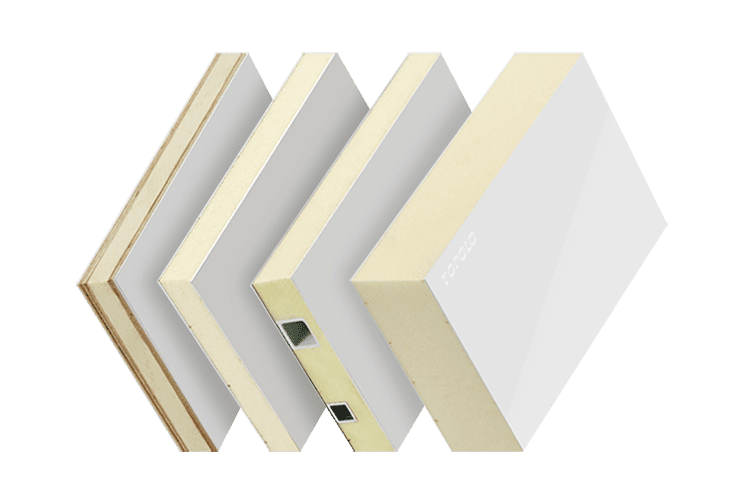

High-strength structure

A complete “skeleton” frame structure is embedded inside the truck body panel. These “skeleton” materials are made of fiberglass profiles, aluminum profiles or waterproof plywood, which are evenly distributed inside the panel. This not only enhances the structural strength of the panel, but also provides sufficient nail holding force for the installation of external metal parts (such as guide rails, hinges, edge profiles, flooring, etc.).

Modular Design

Each side of a refrigerated truck body is a complete composite panel. The truck box is fixed by aluminum profiles, and the panels firmly connected together by rivets and sealants. Therefore, assembling the box is a simple and efficient task, and when it needs to be repaired, it is also very easy to disassemble.

Thermal Insulation

There is no gap between the box panels, and high-performance rubber seals are used between the door panels and the door frames, making it completely waterproof. The entire box is made of low thermal conductivity materials, and the thermal bridge problem is eliminated at the corners of the box. The refrigeration unit has low consumption and high thermal insulation effect. With excellent thermal insulation performance, even if the refrigeration unit fails, the internal low temperature can still be maintained for several hours at normal temperature.

Application of New Composite Materials

FRP (fiberglass reinforced plastic) composite materials replace metal panels for the construction of refrigerated truck bodies, which is a breakthrough in body construction technology. FRP materials are lightweight, waterproof, and heat-insulating, making them ideal materials for refrigerated truck body skins. TOPOLOGROUP creatively combines thermosetting FRP with thermoplastic FRP (CFRT-continuous fiber reinforced thermoplastic), making the refrigerated truck body beautiful in appearance, easy to clean, durable, and cost-effective.

- Consistent smoothness and flatness inside and outside.

- Reduce manufacturing costs and obtain a more durable refrigerated body.

- The outer skin is thermosetting FRP, and the inner skin is CFRT. That is, a smooth and flat appearance is obtained, and the manufacturing cost is reduced.

Refrigerated Truck Floor

The refrigerated truck floor is made of lightweight and durable aluminum alloy plates combined with high-performance composite materials. This design not only provides excellent load-bearing capacity and impact resistance, but also ensures anti-corrosion and anti-slip performance.

- Good anti-skid performance, suitable for light refrigerated truck boxes.

- Easy to drain and clean. It is suitable for light and medium duty refrigerated truck bodies.

- It is more conducive to drainage and cold air circulation, suitable for medium and large refrigerated truck boxes.

- The non-slip fiberglass floor not only prevents operators from slipping, but also enhances the visual appeal of the vehicle.

Door Styles are Diversified

Refrigerated customized box doors come in different styles to meet diverse transportation needs and aesthetic preferences.

Custom Accessories

You can specify the specifications and performance of the accessories. We can customize the accessories to meet the user’s local regulations or customs.

These accessories include:

- Door locking system.

- Door frame.

- Door seals.

- Hinges.

- Door retainer.

- Refrigeration unit.

- Rear bumper.

- Side guards.

- LED lights.

- Aluminum edging.

- Kick plates.

- E-tracks.

- Subframe.

- Chassis frame.

- Lift platform.

- Roll-up door.

- Curtain.

- Anti-collision rubber rod.

- Corner caps.

- Hooks, etc.

Choose Assembly Forms – CKD/SKD/CBU

Refrigerated truck bodies are delivered to customer destinations in a variety of assembled forms, including CKD, SKD, and CBU.

☑ CKD (Completely Knocked Down)

The individual parts of the truck body are disassembled and transported to the destination as a parts package. Then, they are assembled at the destination.

☑ SKD semi-knocked down)

Important parts of the truck body are already assembled, while other parts are still disassembled and transported together to the destination for final assembly.

☑ CBU (Completely Built Units)

All assembly and commissioning work has been completed at the manufacturing plant, and the truck body will be transported to the user’s site in a fully assembled form. This method is suitable for customers who want to put it into use immediately without additional assembly or modification.

Cases – 4.2m Refrigerated Truck Bodies

- Size: 4200x2050x2170mm.

- Box Panels: XPS foam sandwich panels( outer skin is FRP, inner skin is CFRT).

- Panel Thickness: Floor 94mm; Others 80mm.

- Floors: 6061 Diamond aluminum plates.

- Door Frame: 2.0mm SS 304 Stainless Steel.

- Door Locks: Glossy SS 304 Stainless Steel; Hidden lock bars.

- Hinges: Glossy SS 304 Stainless Steel.

- Door Retainers: Magnets.

- Edge Profiles: 6061 Aluminum Alloy.

- Subframe: Z350 Galvanized Steel.

- Kick Plate: 6061 trapezoidal aluminum plate.

- Sealing Strips: High elastic EPDM rubber.

More Application Cases

We also customize dry freight truck bodies, refrigerated box trailers, ambulance boxes, etc. Please consult us for more information.