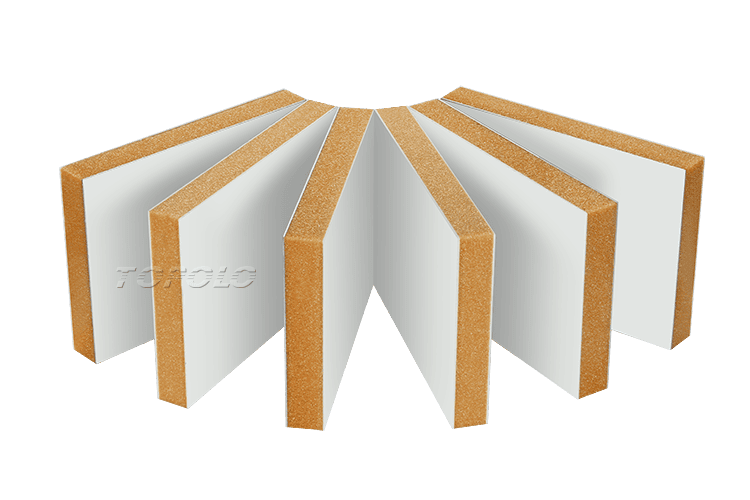

PVC Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels

The new PVC foam sandwich panel developed by TOPOLOGROUP, as a composite panel with excellent performance, cleverly integrates the unique characteristics of PVC foam core material, and on this basis, through structural innovation and material optimization, it has greatly expanded the application direction and become an ideal choice in multiple fields.

PVC Foam Sandwich Panel Manufacturer

As China’s leading PVC foam sandwich panel manufacturer, TOPOLOGROUP has won the favor of global customers with its high-quality, high-specification and high-performance products. Its customized service is one of its core competitive advantages. By deeply meeting the personalized needs of different industries and scenarios, it provides customers with a full-chain solution from material selection to finished product delivery.

Specifications

| Length | Up to 12m. |

| Width | Up to 3.2m. |

| Thickness | 10-150mm |

| Skin | FRP (glass fiber reinforced plastic) sheet. |

| CFRT (continuous fiber reinforced thermoplastic) sheet. | |

| Aluminum alloy sheet. | |

| Core | Hard PVC (polyethylene) foam. (Density: 40-250kg/m³) |

| Adhesive | Two-component polyurethane |

| Unsaturated polyurethane | |

| Embedded materials (optional) | Timbers, aluminum profiles, fiberglass profiles, steel profiles, etc. |

| Processing service | CNC machining |

Product Profiles

- The structure of PVC sandwich panels is simple. It usually consists of skin material and foam core material, which are bonded by high-strength glue.

- The pore size of PVC foam surface is large, so it can firmly absorb adhesive, so its surface usually does not need to be grooved for diversion adhesive.

- Rigid PVC foam is harder than other brittle foams (PU, XPS, etc.), so the structural strength of PVC sandwich panels is higher, and it usually does not need to embed skeleton materials to increase strength.

PVC Foam

As a thermal insulation material with excellent comprehensive performance, PVC (polyvinyl chloride) foam has significant advantages in:

- Lightweight

- High strength and rigidity

- Good Water Resistance

- Chemical Resistance

- Excellent Thermal Insulation

- Flame Retardant

- Easy to Process

Skin and performance

As a core material with excellent performance, PVC foam, when combined with skins of different materials, can give full play to the characteristics of each material to form a composite panel with differentiated characteristics and exclusive application scenarios.

FRP Skin PVC Foam Core Sandwich Panels

FRP (Glass Fiber Reinforced Plastic, also known as GRP) is a composite material with glass fiber as reinforcement and resin as matrix. It is lightweight, waterproof, and heat-insulating. When combined with PVC foam core, it forms a composite panel with multiple advantages.

CFRT Skin PVC Foam Core Sandwich Panels

CFRT (Continuous Fiber Reinforced Thermoplastic) is a new high-performance FRP material. It is made of multiple layers of thermoplastic UD tapes laid at different angles. It has high tensile and compressive strength and is very durable.

Aluminum Skin PVC Foam Core Sandwich Panels

The skin of the sandwich panel with aluminum alloy sheet is a lightweight and durable choice, with a variety of choices in aluminum sheet color and texture.

Applications

Given the excellent performance of PVC foam sandwich panels, it is widely used in high-standard and luxurious products.

RV bodies

- Truck camper bodies

- Off-road trailers.

- Expedition trucks.

- Caravans. .

- Teardrop trailers.

- Rooftop tents, etc.

Truck & trailer bodies

- Refrigerated trucks.

- Dry cargo trucks.

- Ambulance boxes.

- Food trailers.

- Day-old chicken transport trucks.

- Airline containers.

- Portable trailers, etc.

Buildings

(Wall panels, partitions, roof panels, door panels of permanent or movable buildings.)

- Factory buildings.

- Outdoor temporary housing.

- Clean rooms.

- Cold rooms.

- Warehouses.

- Hotels.

- Industrial equipment housings, etc.

Furniture

- Cabinets.

- Bed panels.

- Desktop panels.

- Partitions, etc.

Marines

(Floor panels, wall panels, roof panels, etc. of rooms for boats.)

- Yachts.

- Cruise ships.

- Fishing boats.

- Patrol boats, etc.

Public transportation

(Floors, partitions)

- Subway.

- Light rail.

- Tram.

- High-speed rail.

- Bus.

Materials and Processing

High-quality raw materials

- PVC foam is colorless, odorless, uniform in specifications and color.

- The skin material meets various mechanical and chemical performance tests.

Advanced composite technology

High-pressure vacuum composite technology allows the foam core and skin material to achieve high-strength bonding and extremely flat surface of the sandwich panel. The maximum size of our composite panels can reach 12mx3.2m.

High-precision CNC machining

High-precision CNC machining can achieve precise molding of complex-shaped panels in one processing. Our factory is equipped with multiple high-precision CNC machining platforms, which are designed to meet the needs of large-scale and high-difficulty panel processing.

Other Foam Sandwich Panels

We also produce XPS (extruded polystyrene), PET (polyethylene terephthalate), PU (polyurethane) foam core sandwich panels. Or customize composite materials of various foam systems according to your needs.