Polyurethane Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels

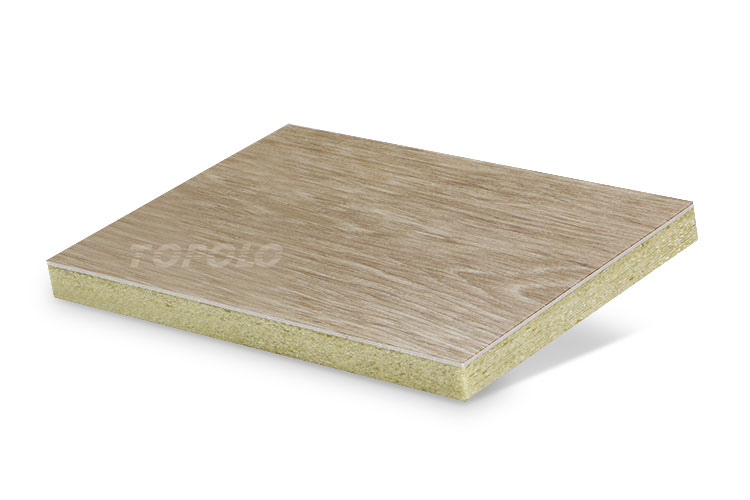

Thermal insulation composite panels

PU (polyurethane) foam is a core material with excellent thermal insulation performance, so PU sandwich panels are the first choice for many box builders to build thermal insulation boxes.

As a professional flat sandwich panel manufacturer, TOPOLOGROUP relies on rich manufacturing experience, advanced production equipment and excellent technology to customize PU sandwich panels for enterprises and individuals around the world. These panels have shown reliability and stability in local engineering projects.

Specifications

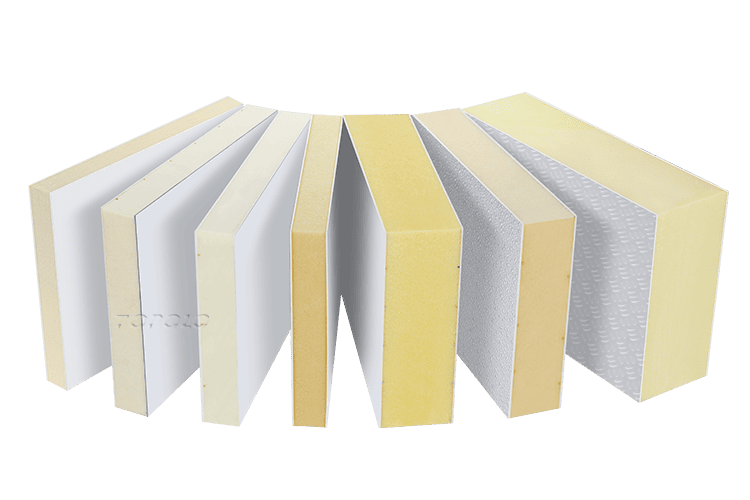

| Facing | FRP (Glass Fiber Reinforced Plastic) sheet. |

| CFRT (Continuous fiber reinforced thermoplastic) sheet. | |

| Aluminum sheet. | |

| Coated steel sheet. (GI, GL, PPGI, PPGL) | |

| Core | PU (Polyurethane) foam. (Density: 28-50kg/m³) |

| Composite Method | Adhesive. |

| Thickness | 10-150mm. |

| Length | ≤12000mm. |

| Width | ≤3200mm. |

Skin Types of Polyurethane Foam Sandwich Panels

When designing PU sandwich panels, a wide variety of surface materials can be taken into account. Relying on high-performance adhesives, polyurethane foam cores can be used with different surface materials, such as metal (aluminum, steel), plastic (FRP, CFRT), so that makes the final panel meet different application requirements. If you require unique surface materials to be applied to PU sandwich panels, we will custom make these panels for you.

Common Application of PU Foam Sandwich Panels

Truck & Trailer Bodies

- Used in the bodies of refrigerated trucks and insulated trucks, etc., to help maintain a low temperature environment and ensure the transportation and storage of perishable items.

Modular Buildings

- Used as exterior wall panels, roof panels and interior wall panels, especially suitable for buildings that require insulation, such as cold storage, refrigerated warehouses, offices and commercial buildings.

Agricultural Greenhouses

- Used in greenhouses and agricultural buildings, it provides excellent thermal insulation performance, helps regulate indoor temperature and prolongs the crop growing season.

Industrial Facilities

- Used in the shell of industrial equipment, providing insulation and waterproofing functions.

How We Provide High Standard PU Foam Sandwich Panels

- High-quality raw materials

- Optimized design

- Advanced technology

01. Insulated PU (polyurethane) Foam Core

The PU foam core has extremely low thermal conductivity and water absorption due to its unique closed-cell cell structure.

- Density: 28-50 kg/m³.

- Thermal Conductivity: 0.020-0.030 W/m·K.

- Compression Strength: 200-600 kPa.

- Water Absorption: < 1%.

- Hardness: 25-70 Shore A.

- Bending Strength: 200-500 kPa.

02. PU foam sandwich panels are made by spray adhesive technology

In this process, adhesive is sprayed onto the skin and core materials, then pressure is applied under vacuum and high pressure to bond them together. Compared to other sandwich panel manufacturing methods, adhesive-bonded sandwich panels offer a flexible, efficient, and cost-effective solution, allowing for customization of thickness, size, structure, strength, and other factors to meet the user’s application requirements.

03. How to increase the structural strength of PU foam sandwich panels

PU foam is very fragile, so when building large-scale, high-load-bearing strength sandwich panels, relying solely on the “foam + skin” structure cannot achieve the performance requirements.

“Skeleton” materials are embedded inside to enhance the structural strength of the panel.

A set of evenly distributed “skeletons” made of wood, steel pipes, aluminum profiles or high-strength plastics are embedded inside the PU foam sandwich panel. In order to ensure the lightweight of the panel, our engineers carefully designed the structure to reasonably balance the strength and weight of the panel.

04. High-precision CNC machining

High-precision CNC machining is faster, more accurate, and more consistent.

Rely on computer numerical control processing to achieve precise and fast cutting, drilling, milling, engraving and other operations on PU foam sandwich panels to ensure the dimensional consistency of large batches of panels.

- The size deviation is within 1mm.

- The thickness deviation is within 0.1mm.

To learn more about PU foam sandwich panels and get relevant solutions, please contact us. In addition, we also provide XPS, PET, and PVC foam sandwich panels.