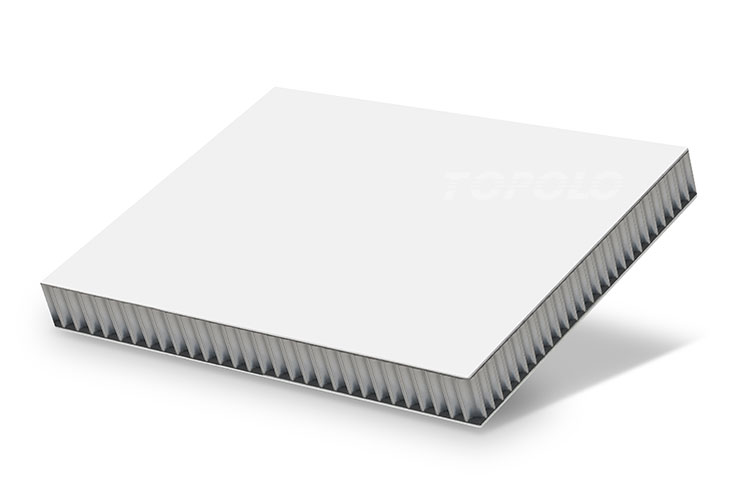

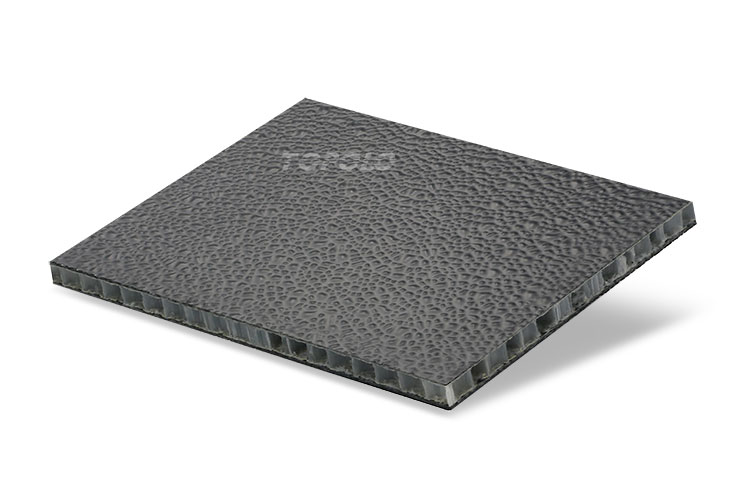

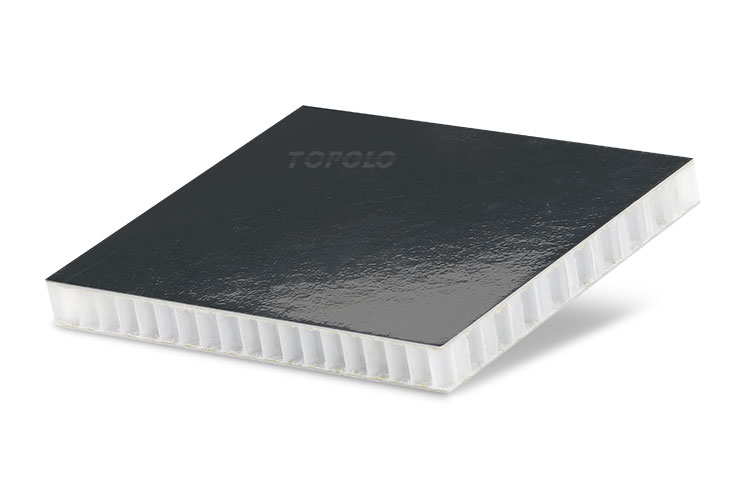

Polypropylene Honeycomb Sandwich Panels

Lightweighting is a major trend in modern engineering structural research. Among numerous lightweight materials, polypropylene honeycomb is favored by many engineers for its unique properties and structure. The core advantage of polypropylene honeycomb material lies in its biomimetic structural design. It mimics the structure of a natural honeycomb, forming a large number of regularly arranged hollow honeycomb cells within the material. This structure significantly reduces its weight while efficiently carrying external loads by distributing stress. Compared to traditional solid materials, polypropylene honeycomb exhibits superior mechanical properties per unit weight, providing an ideal solution for balancing lightweighting and high strength.

Lightweight & High Strength Composite panels

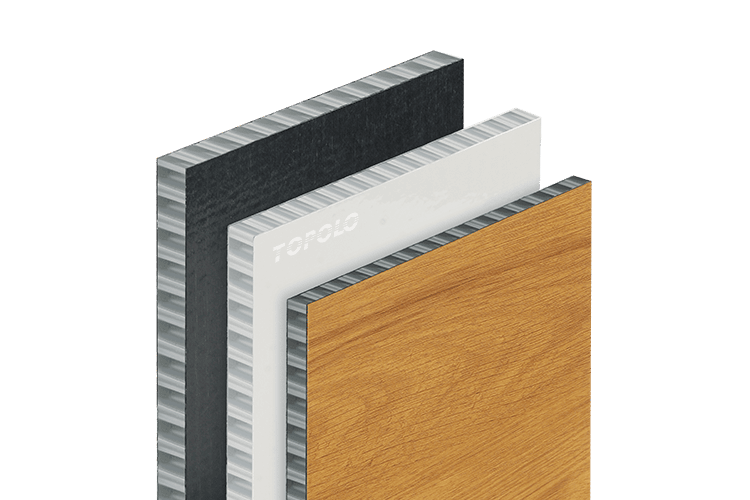

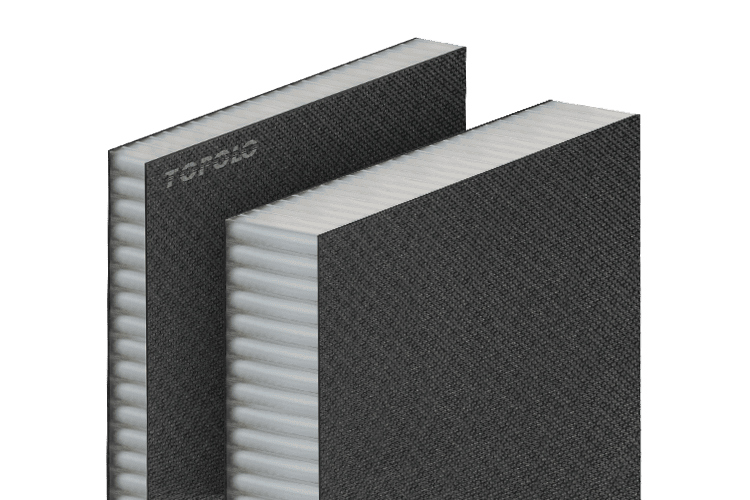

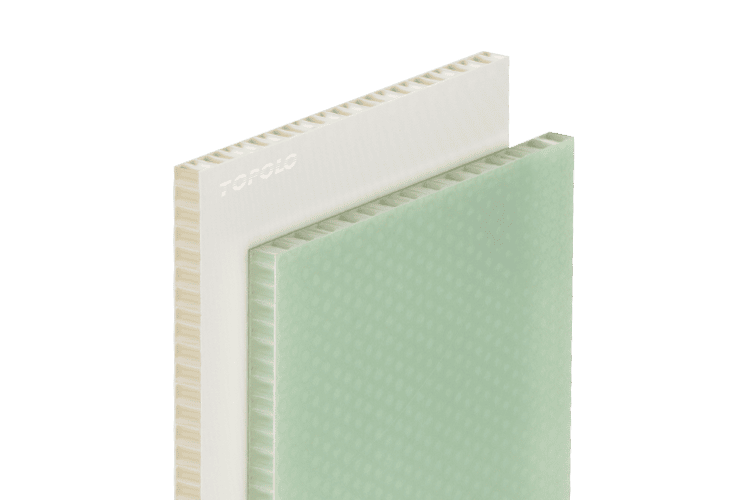

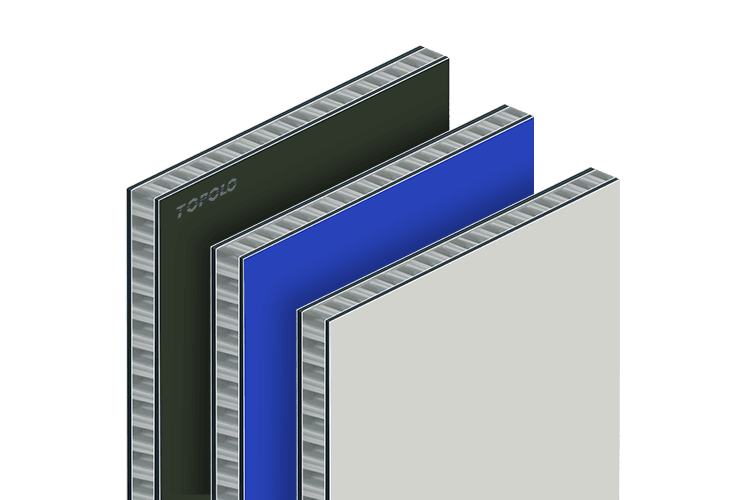

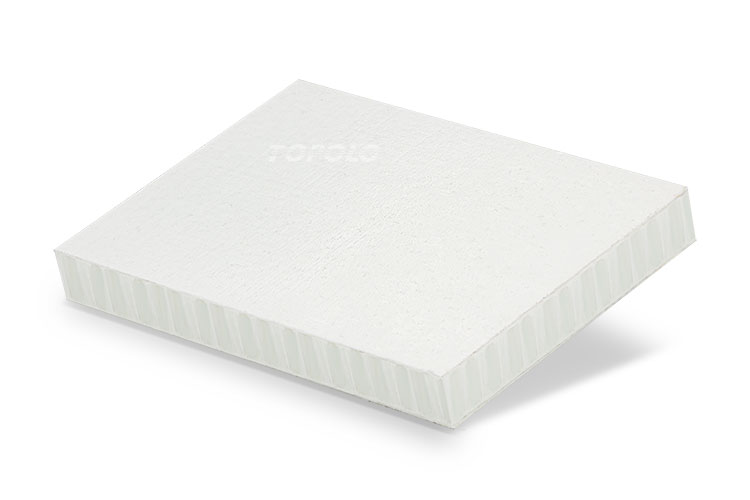

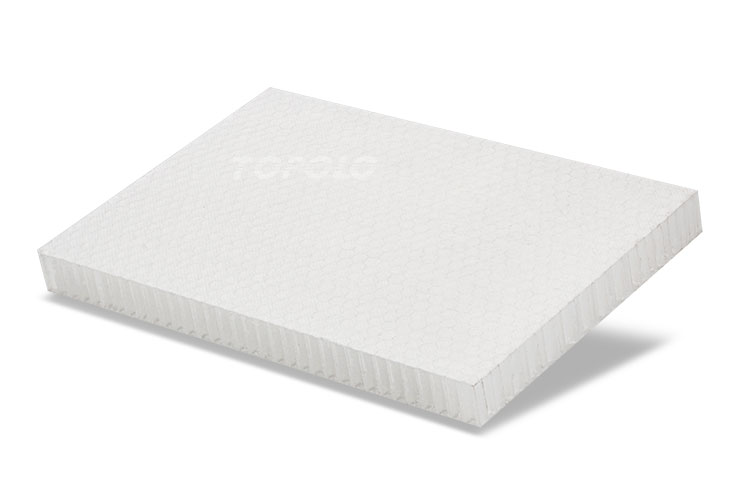

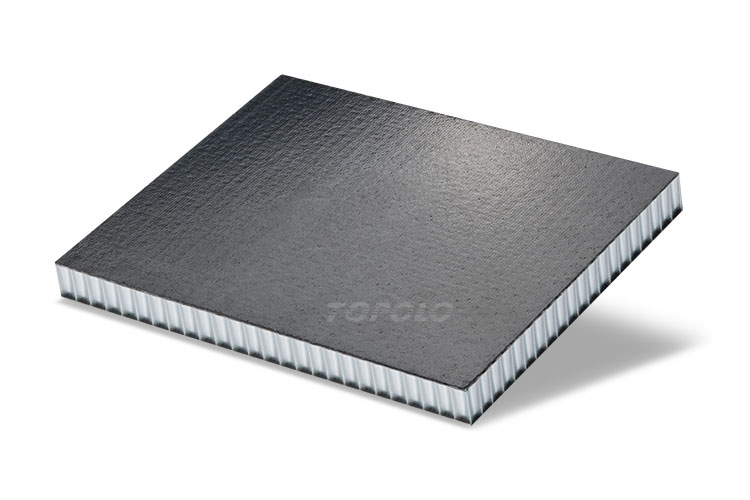

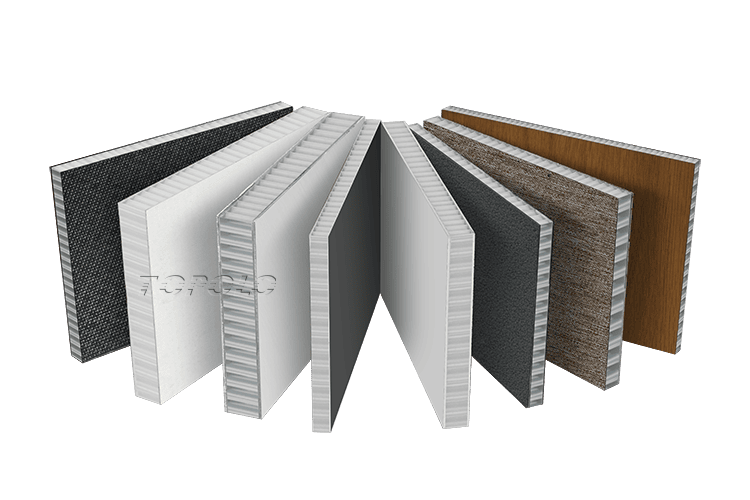

Composite sandwich panels with polypropylene honeycomb as the core material are characterized by their light weight and high strength. These sandwich panels typically consist of three layers: top and bottom layers of high-strength facesheet material, with a polypropylene honeycomb core in the middle. Through appropriate interface design, this composite structure fully utilizes the strengths of each component.

Working Principle

- The facings carry tensile, compressive, and bending loads, providing structural rigidity and strength.

- The honeycomb core, through its unique cellular structure, distributes the loads transferred from the facings throughout the structure.

Specification of Polypropylene Honeycomb Sandwich Panels

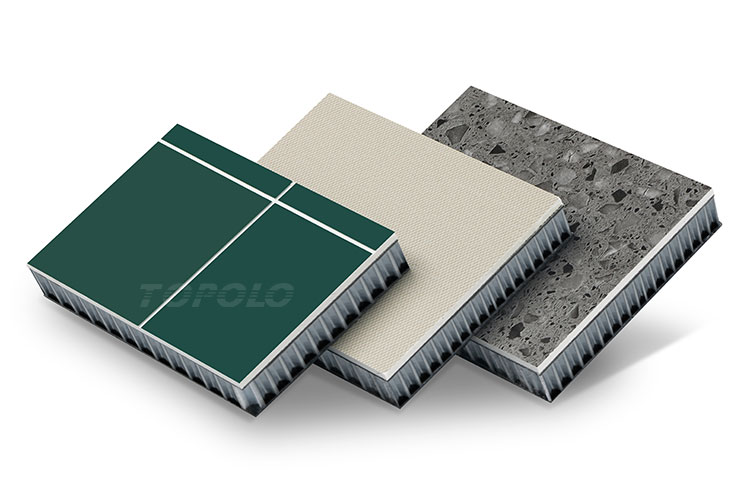

| Facing | GRP/FRP (Fiberglass Reinforced Plastic) sheets. |

| CFRT (Continuous Fiber Reinforced Thermoplastic) sheets. | |

| Carbon fiber prepreg sheets. | |

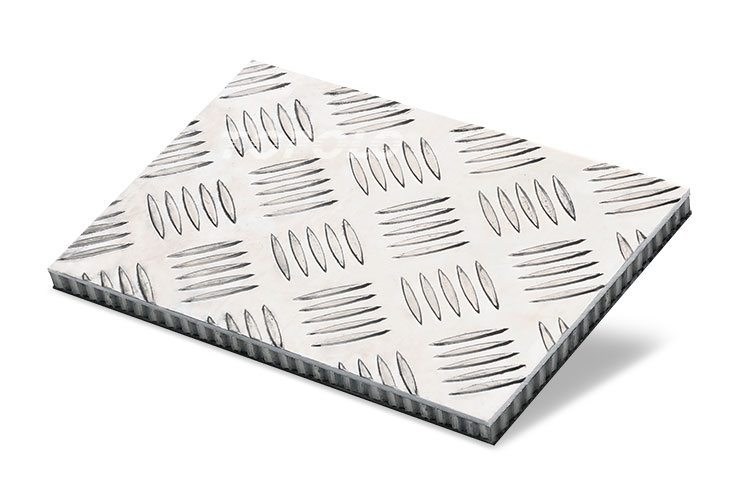

| Aluminum sheets. | |

| ACP (Aluminum Composite) panels, etc. | |

| Core | PP (Polypropylene) Honeycomb. |

| Composite methods | Adhesive bonding, thermal composite. |

| Thickness | 10-150mm. |

| Length | Max 12000mm. |

| Width | Max 3200mm. |

Performance Parameter of Polypropylene Honeycomb Core

| Cell size(mm) | 8 | 10 | 12 |

| Density(kg/m³) | 80 | 75 | 70 |

| Compressive Strength(MPa) | 1.66 | 1.58 | 1.47 |

| Compressive Modulus(MPa) | 45.7 | 41.2 | 38.9 |

| Shear Modulus(MPa) | 0.50 | 0.45 | 0.40 |

| Operating Temperature(℃) | -40-80 | -40-80 | -40-80 |

| Thermal insulation U value | 2.2 | 2.2 | 2.2 |

Discover Our Honeycomb Panel Products

Application Scenario

The “lightweight & high-strength” characteristics of polypropylene honeycomb sandwich panels give them broad application prospects in aerospace, rail transportation, automobile manufacturing, architectural decoration, shipbuilding and other fields.

- Dry freight trucks, dry cargo trailers, dropside trucks, etc.

- Caravans, teardrop trailers and more.

- The interior facilities of cruise ships and yachts.

- Mobile buildings, stages, scaffolding, building formwork, etc.

- Cabinets, partitions, ceilings, tabletops, etc.

- Aircraft floors, boarding aisles, terminal interior facilities, etc.

- Pickleball paddles, portable ping pong tables, etc.

- Floors and partitions of high-speed railways, subways and buses.

Composite Methods for Honeycomb Sandwich Panels

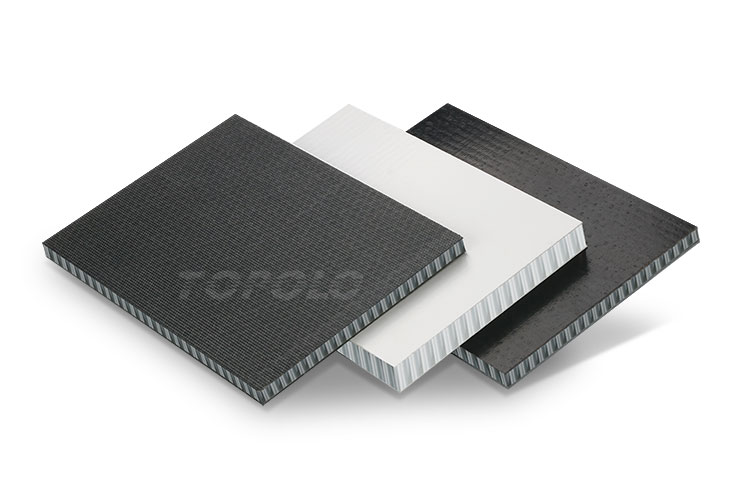

Adhesive Composite Honeycomb Panels

Adhesives are used to bond materials of different properties. The skin and honeycomb core are bonded together using glue, then pressure is applied and the panels are fixed in place for a period of time. This method is primarily used to bond polypropylene honeycombs with non-thermoplastic skin materials such as FRP/GRP, carbon fiber, and metal skins.

Thermoplastic Composite Honeycomb Panels

This is a new method for producing honeycomb composite panels, primarily for thermoplastic skin materials (CFRT). Since the polypropylene honeycomb is a thermoplastic, it can be effectively bonded to the thermoplastic CFRT through heating. Compared to adhesive-bonded honeycomb sandwich panels, this method offers a more efficient production process, resulting in a secure, stronger bond and greater resistance to cracking.

Leading Manufacturer – TOPOLOGROUP

As China’s leading manufacturer of new lightweight composite panels, TOPOLOGROUP uses innovative material technologies to produce high-specification polypropylene honeycomb sandwich panels, providing lightweight solutions for various industries. TOPOLOGROUP has established professional production lines for thermoplastic composite honeycomb panels and adhesive composite honeycomb panels, and both product quality and output are among the best in China.

High-precision Machining

The polypropylene honeycomb sandwich panels that are finished off the composite production line are often not usable directly and require modification or further processing to become finished products that meet the standards of the final application. The structure of honeycomb panels makes machining significantly more difficult than with traditional solid materials, especially for large or thin-walled panels. TOPOLOGROUP’s high-precision, 5-axis, synchronous CNC machining platforms easily handle cutting, drilling, and other machining operations.

For more information about polypropylene honeycomb sandwich panels, please contact us.