The woven roving glass fibers are embedded in a polymer matrix. The resulting panels are both lightweight and very strong, with excellent resistance to moisture, chemicals, and environmental conditions.

Specification

- Panel Width: Up to 3200mm.

- Roll Length : 60-200m.

- Thickness: 1.5mm, 2.0mm or customized.

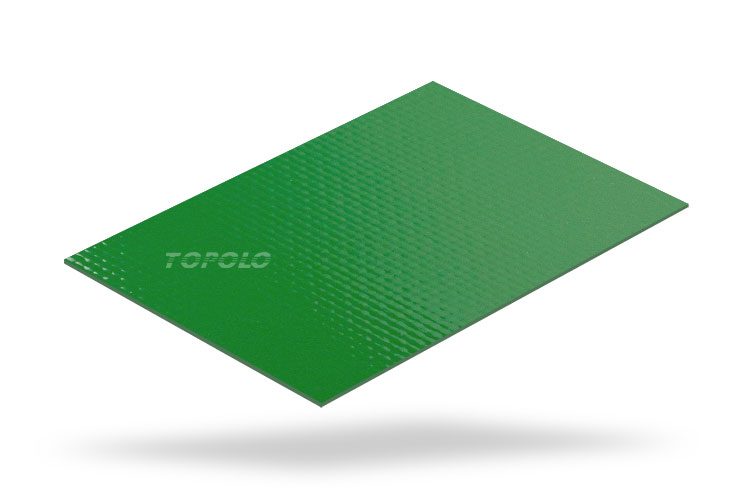

- Surface: Gel Coat.

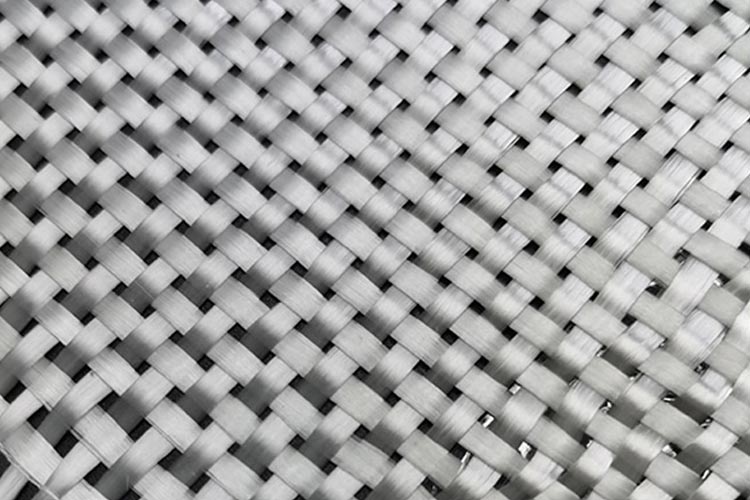

- Fiber Type: Woven roving.

- Resin Type: Unsaturated polyester.

- Color: White, Grey, Black, Yellow, Red, Blue, Green, etc.

DESCRIPTION

Product Features

- Lightweight.

- Bending Resistant.

- Tear Resistant.

- Scratch Resistant.

What is plain woven roving fiberglass?

Plain roving weave is a fabric made of continuous strands of glass fibers woven in a simple up-and-down pattern. It is the basic fiberglass fabric used in composite material manufacturing. It offers high strength, high modulus, and structural stability, which improves the tensile, flexural, and tear resistance of FRP sheets. This type of FRP sheet is thinner, but its surface is not as smooth as that of fiberglass mat.

Structural Diagram

Performance Parameters

| Thickness | mm | 1.50 | 2.00 | 2.00 (Double Woven Roving) |

| Density | g/cm1 | 1.50 | 1.50 | 1.5 |

| Weight | g/m2 | 2250 | 3000 | 3000 |

| Glass Content | % | 30 | 30 | 31 |

| Hardness | Barcol | 40/42 | 40/42 | 40/42 |

| Tens ile Strength | Mpa | 105 | 110 | 145 |

| Tensile Modulus | Mpa | 7150 | 7420 | 9980 |

| Flexural Strength | Mpa | 150 | 158 | 217 |

| Shear Srength | Mpa | 95 | 100 | 120 |

Woven Roving Fiberglass vs Chopped Strand Fiberglass Mat

Woven roving fiberglass is stronger, more durable, and ideal for high-performance FRP panels.

Chopped strand fiberglass mat is more flexible, easier to handle, and provides a smoother surface for FRP. panels

Application

It can be combined with foam core materials (such as PET, PVC, and XPS), honeycomb core materials, and plywood core materials to create lightweight, high-strength sandwich panels.

- Construction: Wall panels, roof panels, skylights, and decorative panels.

- Transportation: Refrigerated trucks, dry vans, and recreational vehicles.