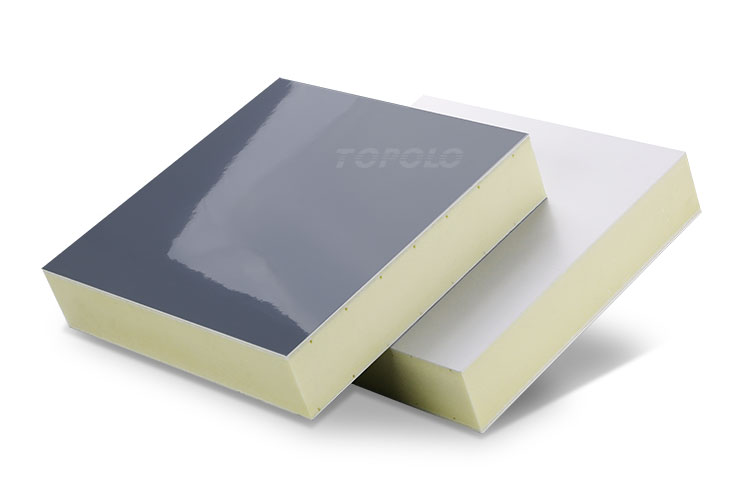

FRP Skin XPS Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels » XPS Foam Sandwich Panels

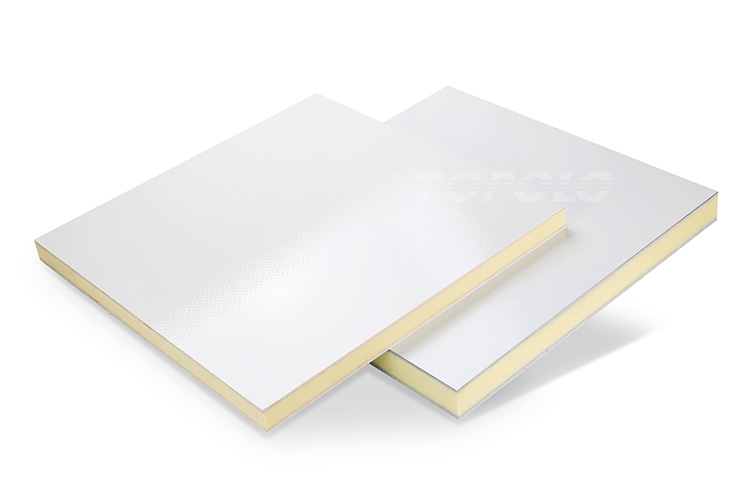

FRP skin XPS foam sandwich panels combine the characteristics of rigid XPS (extruded polystyrene) foam and FRP (glass fiber reinforced plastic also called GRP or GFRP), with excellent performance, light weight, thermal insulation, waterproof and moisture-proof, easy to process, easy to clean, aesthetic, etc., and are widely used in various industries.

Product Features

Extremely lightweight, greatly reducing load and increasing efficiency

The density of XPS foam is low (generally less than 50kg/m³), and the reduction in the weight of the composite board can significantly reduce the carrier load, making it easier to carry and assemble.

Highly efficient heat insulation, long-term temperature control and stability

The low thermal conductivity of XPS foam (usually ≤0.035 W/(m・K)) and the synergistic barrier effect of the FRP skin can effectively block the transfer of cold and hot energy and achieve long-term stable temperature control.

Full-effect waterproof, weather-resistant and corrosion-resistant

FRP is extremely hydrophobic and difficult for water to adhere; the XPS foam core is a closed-cell structure with extremely low water absorption (usually ≤1.5%). Even if it is soaked for a long time, it will not absorb water and expand, fundamentally avoiding deformation and mildew caused by moisture. Therefore, FRP skin XPS foam sandwich panels are suitable for high humidity and high salt fog environments, and can resist water vapor erosion and chemical corrosion.

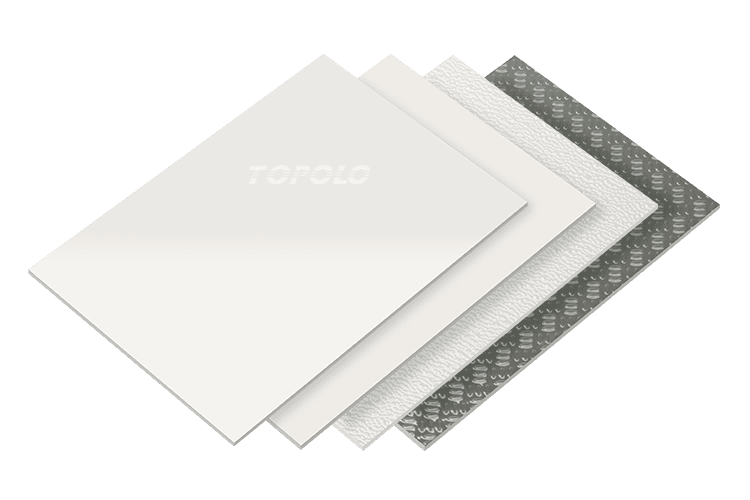

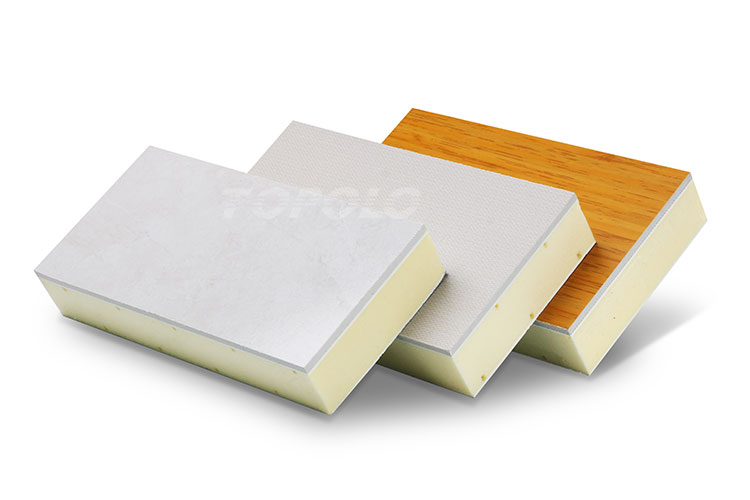

Flexible surface style adaptation

The surface adopts customized gel coating FRP, which is not only flat and glossy, but also can be customized in a variety of colors and textures according to needs, easily matching the decoration style of different scenes. In addition, the color stability of FRP skin is strong, and it is not easy to fade after long-term use, and it keeps its brightness as long as new.

Convenient cleaning, extremely low maintenance cost

The surface of FRP is smooth and non-porous, and stains (such as dust, oil, and fingerprints) are difficult to penetrate and adhere. Ordinary dust can be rinsed with clean water or wiped with a wet cloth. Stubborn stains can be quickly removed by rubbing with a neutral detergent.

Easy to process and assemble

FRP skin XPS foam sandwich panels are very suitable for various cutting-type machining while maintaining machining accuracy and stability of finished product quality.

Specifications

Basic Structural Diagram

Details

How to enhance the structural strength of the panel?

Pre-embedded “skeleton”

- Build an internal support frame to enhance load-bearing capacity

Pre-embedded frame inside the foam core panel is like implanting “skeleton” into the panel, which can fundamentally improve the anti-deformation ability and dimensional stability, especially suitable for large-size panels.

Adding an energy-absorbing layer

- Build an internal support frame to enhance load-bearing capacity

On the side of the panel that is often subjected to force, add an energy-absorbing layer (usually plywood, composite materials, etc.) between the skin and the foam core. Just like adding a “cushion” to the panel, it can absorb external impact forces (such as collision, extrusion, vibration) through material deformation or energy conversion, reducing damage to the internal core structure.

Applications

Vehicle box bodies

- Camping RVs.

- Refrigerated trucks.

- Refrigerated trailers.

- Ambulances.

- Catering trailers.

- Day-old chicken trucks, etc.

Buildings

- Mobile homes.

- Cold rooms.

- Clean rooms.

- Grow rooms.

- Farms.

- Industrial equipment enclosures, etc.

Marine

- Yachts.

- Fishing boats.

- Cruise ships.

- Floating structures, etc.

Production and Processing

High-quality raw materials

- We select food-grade FRP sheets and flame-retardant foam core materials and undergo rigorous testing to ensure that material performance meets standards, quality is flawless, and specifications are uniform.

Advanced manufacturing technology

- The sandwich panels are formed under high pressure in a vacuum environment to ensure a flat surface, tight bonding, and strength far exceeding that of ordinary composite panels.

Customized size

- Our composite panels can be manufactured in a maximum size of 12m x 3.2m, which is consistent with the current largest container size of 40 feet (12.03 meters).

High-precision machining

- Using high-precision CNC processing, we can manufacture panels of any shape to meet personalized design requirements while maintaining consistent product accuracy and quality.