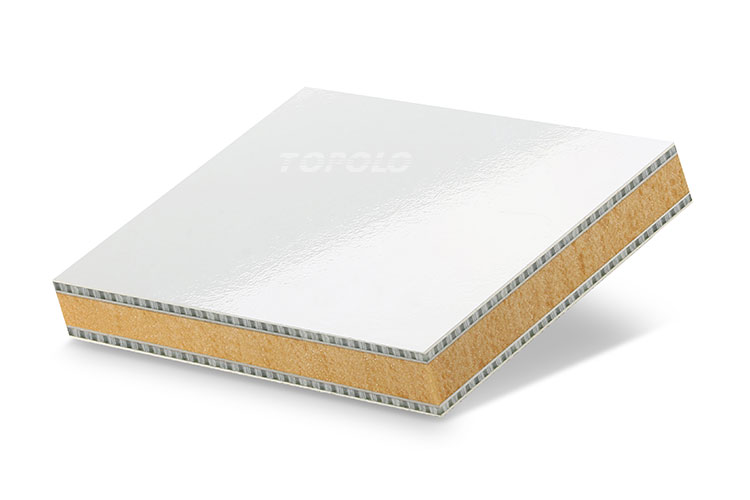

FRP Skin PVC Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels » PVC Foam Sandwich Panels

- Lightweight

- Thermal Insulation

- Moisture and Mold Resistant

- Compressive Strength

- Flame Retardancy

FRP skin PVC foam sandwich panels combine the properties of PVC (polyvinyl chloride) foam and FRP (fiberglass reinforced plastic) to produce panels with a range of excellent properties. The sandwich panel manufactured through a one-piece composite process has more stable performance and wider applications than spray foam sandwich panels.

We are a leading FRP sandwich panel manufacturer in China, providing customized solutions from design to production for global companies. Our factory is equipped with industry-leading composite panel production lines and utilizes unique production processes to meet individual customer design needs.

- We offer custom sizes, thicknesses, and colors.

- Panels can be cut to specific design requirements.

- Provide related accessories services.

Product Features

Lightweight

Compared to metal composite panels, the FRP + foam construction significantly reduces overall weight.

Thermal Insulation

The closed-cell structure of the PVC foam core traps air, creating a barrier to heat transfer and providing excellent insulation.

Moisture and Mold Resistant

The PVC foam core itself absorbs virtually no water, preventing expansion or rot. The impermeable FRP skin further prevents moisture penetration.

Compressive Strength

PVC foam’s compressive strength far exceeds that of other insulating core materials, making FRP + PVC constructions an ideal choice for applications requiring a balance of strength, durability, and functionality.

Flame Retardancy

PVC foam contains a significant amount of chlorine, a natural flame retardant. When exposed to flame, chlorine releases hydrogen chloride (HCl) gas, forming a flame retardant barrier that inhibits the spread of flames and reduces combustion speed.

Specifications

| Facing | Gelcoat FRP (Glass Fiber Reinforced Plastic) sheet. (Thickness: 0.7-5.0mm) |

| Core | PVC (Polyvinyl Chloride) foam. (Density: 40-250kg/m³) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Thickness | 10-150mm. |

| Length | ≤12000mm. |

| Width | ≤3200mm. |

| Frame Materials | Timbers, fiberglass profiles, aluminum profiles, sheet metal, etc. |

| Working Temperature | 40℃ to +80℃ |

Schematic Diagram

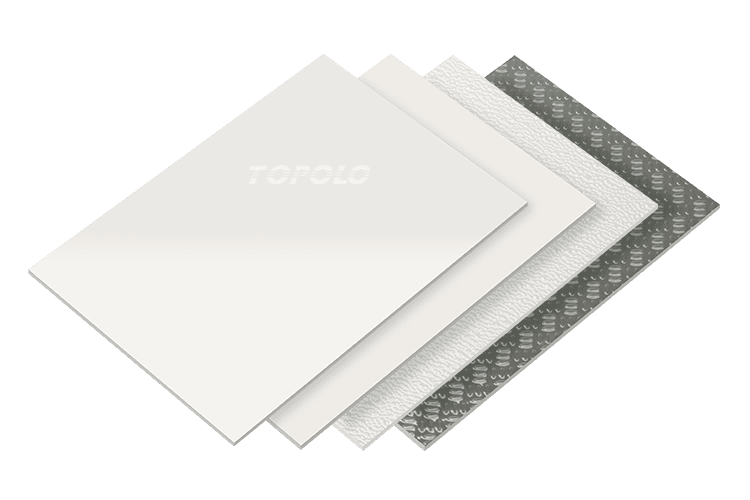

UV Resistant FRP Sheets

FRP sheet is a mixture of resin matrix and glass fiber. Its thickness, color, surface treatment, etc. can be customized according to needs. FRP panels can be manufactured in a variety of colors, textures, and finishes (such as matte, embossed, or rough).

- The surface of FRP is treated with UV protection.

- Flame retardant is added to FRP.

- Alkali-free glass fiber is used as the reinforcement material of FRP.

Common Performance Parameters of FRP sheets

| Thickness | 1.0mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm |

| Weight(Kg/m2) | 1.5 | 2.25 | 3 | 3.75 | 4.5 |

| Glass content(%) | 19 | 25 | 29 | 30 | 30 |

| Tensile strength(Mpa) | 60 | 80 | 92 | 95 | 97 |

| Elongation at break(%) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Elastic modulus(Gpa) | 5.5 | 7 | 7.3 | 7.6 | 7.8 |

| Izod impact strength(KJ/m2) | 45 | 55 | 70 | 80 | 95 |

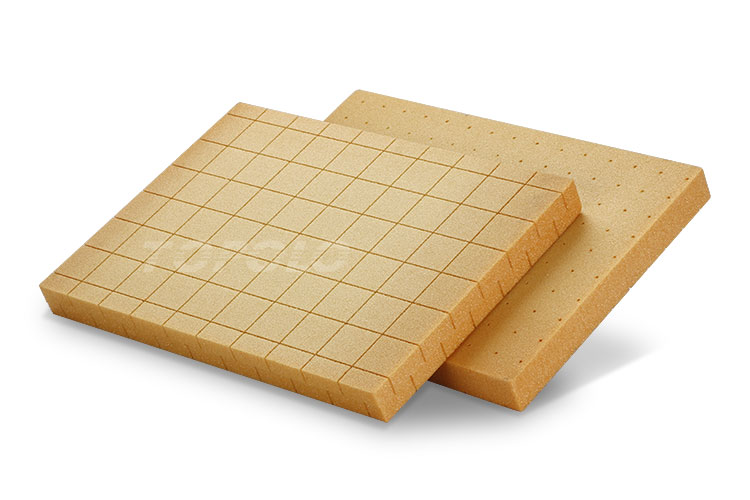

Closed-cell PVC Foam Core

Closed-cell PVC foam is a rigid material with a closed cell structure. Due to its low thermal conductivity and unique honeycomb structure, it performs better than other rigid foams (XPS, PU, PET, EPS) in terms of structural strength, thermal insulation, waterproofing and other properties, and has a balanced overall performance.

PVC Foam Performance Parameters

| Item | P60 | P80 | P100 | P130 | P200 | P250 |

| Density ( kg/m3) | 60 | 80 | 100 | 130 | 200 | 250 |

| Tensile Strength(Mpa) | 1.8 | 2.5 | 3.5 | 4.8 | 7.1 | 9.2 |

| Tensile Modulus(Mpa) | 75 | 95 | 130 | 175 | 250 | 320 |

| Compressive Strength(Mpa) | 0.9 | 1.4 | 2.0 | 3.0 | 4.8 | 6.2 |

| Compressive Modulus(Mpa) | 72 | 90 | 135 | 170 | 240 | 300 |

| Shear Strength(Mpa) | 0.76 | 1.15 | 1.6 | 2.2 | 3.5 | 4.5 |

| Shear Mpdulus(Mpa) | 20 | 27 | 35 | 50 | 85 | 104 |

| Shear Strain(%) | 20 | 30 | 40 | 40 | 40 | 40 |

Application of FRP Skin PVC Foam Sandwich Panels

FRP skin PVC foam sandwich panels are reliable structural materials used in wall panels, partitions, roof panels, and floor materials for various box bodies and buildings. Such as:

- Refrigerated truck bodies.

- Cold rooms.

- Public transportation.

- RVs.

- Temporary housing.

- Yachts and boats.

- Building facades.

- Industrial equipment enclosures.