Flat GRP/FRP Sheet Rolls

High Quality Fiberglass Reinforced Sheets

What is GRP/FRP Sheet?

FRP sheet, short for Fiberglass Reinforced Plastic Sheet, is a composite material composed of glass fiber and resin. It is also known as GRP sheet (Glass Reinforced Plastic Sheet) or GFRP sheet (Glass Fiber Reinforced Polymer Sheet). The glass fiber absorbs most of the external forces, contributing to the material’s strength and rigidity. The resin (usually the thermoset type), as the “matrix,” primarily bonds the glass fibers together, transmits external forces to the fibers, and protects them from environmental damage (such as moisture and chemicals).

FRP Sheets – The Star Product of Lightweight Sheet

Flat FRP, available in rolls or sheets, is used as a cladding material for composite or sandwich panels, replacing metal, wood, or plastic. They are lighter than metal and more durable than wood, and their high modulus properties provide excellent performance in many areas.

Product Features

Lightweight & High Strength

- Lightweight: Compared with metal or other traditional building materials, FRP panels are much lighter, making them easier to transport and install.

- High strength: Despite their light weight, FRP panels are very strong and can withstand certain mechanical shocks and loads, making them suitable for a variety of structural applications.

Corrosion Resistance

- Chemical resistance: FRP materials have excellent resistance to chemicals such as acids, alkalis, and salts, making them very suitable for environments such as chemical plants and laboratories.

- Waterproof and moisture-proof: The structure of FRP panels makes them very waterproof and can maintain their physical properties and appearance even in humid environments.

Electrical insulation

- FRP materials have good electrical insulation and are suitable for places with strict requirements for electrical insulation.

Easy to Process

- Customizable: FRP panels can be customized according to customer needs, including color, thickness, size, etc.

- Easy to cut and install: It can be easily cut, drilled, and fixed, making it easy to construct and install on site.

Specifications of FRP Sheet Rolls

| Fiber Type | Fiberglass felt. Fiberglass cloth. |

| Resin Type | Unsaturated polyester resin (UPR). Vinyl ester resin (VE). Epoxy resin (EP) |

| Fiberglass Content | 30-70%. |

| Surface Treatment | Gelcoat or no. |

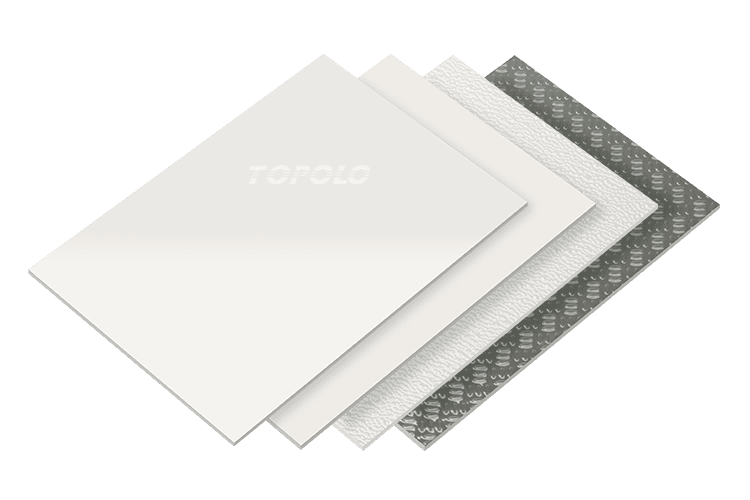

| Surface Color | RAL series. (White, black, yellow, gray, etc) |

| Width | ≤3200mm. |

| Thickness | 0.7-5.0mm. |

| Length | 100-250m/roll. |

Common Performance Parameters of FRP Sheets

| Thickness | 1.0mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm |

| Weight(Kg/m2) | 1.5 | 2.25 | 3 | 3.75 | 4.5 |

| Glass content(%) | 19 | 25 | 29 | 30 | 30 |

| Tensile strength(Mpa) | 60 | 80 | 92 | 95 | 97 |

| Elongation at break(%) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Elastic modulus(Gpa) | 5.5 | 7 | 7.3 | 7.6 | 7.8 |

| Izod impact strength(KJ/m2) | 45 | 55 | 70 | 80 | 95 |

Gel Coat Improves the Performance of FRP Panels

Gel coat is a high-performance coating made from unsaturated polyester resin, vinyl ester resin or other high-performance resins with pigments and additives. Gel coat FRP has significant advantages over uncoated FRP.

☑ Improved Durability

Gelcoat effectively blocks rain, moisture, industrial dust, and weak acids and alkalis, protecting the underlying fiberglass from moisture and corrosion. (Ordinary FRP sheets lack a gelcoat, making the fibers susceptible to sunlight and aging.)

☑ Improved Weather Resistance

For FRP sheets used in outdoor applications, gelcoat with added UV inhibitors provides enhanced weather resistance and a longer service life. FRP is less susceptible to fading or aging even with prolonged exposure to sunlight.

☑ Improved Aesthetic Appeal

After curing, the gel coat layer achieves a mirror-like finish with a smooth, non-fibrous surface and no air pockets, resulting in a superior appearance and texture. Colorants can be added upon request. This not only improves the product’s texture and visual appeal but also makes the overall design more in line with modern aesthetic requirements.

Fiberglass felt reinforcement vs fiberglass woven reinforcement

Glass fiber as reinforcement material can exist in different forms, such as felt, woven fabric and other types.

Fiberglass Felt

Product Features: Resistant to deformation and a smooth surface.

Chopped glass fiber offers uniform texture, excellent air permeability, and excellent compatibility with the resin. It is randomly distributed within the resin. This FRP sheet can be made thicker, resulting in a smooth, flat surface and high hardness, making it less prone to deformation after molding.

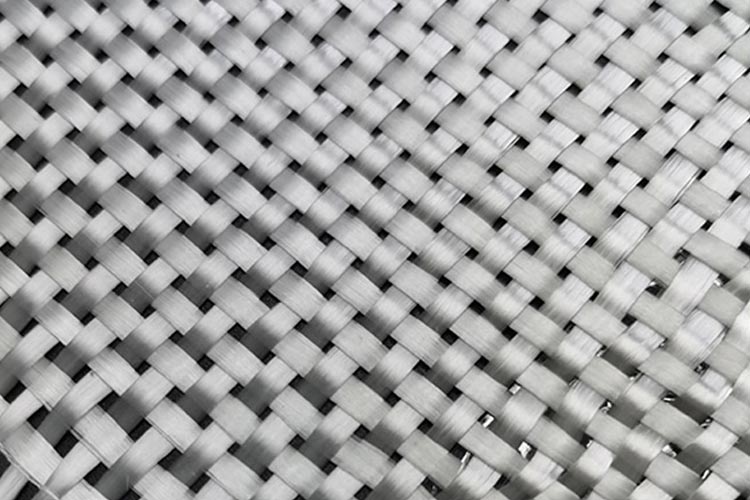

Fiberglass Woven Cloth

Product features: Bending resistance and tear resistance.

Fiberglass fabrics are woven using textile technology to create specific structures (such as plain, twill, and satin). They offer high strength, high modulus, and structural stability, improving the tensile, bending, and tear resistance of FRP sheets. This type of FRP is thinner, but its surface smoothness is inferior to that of fiberglass felt FRP.

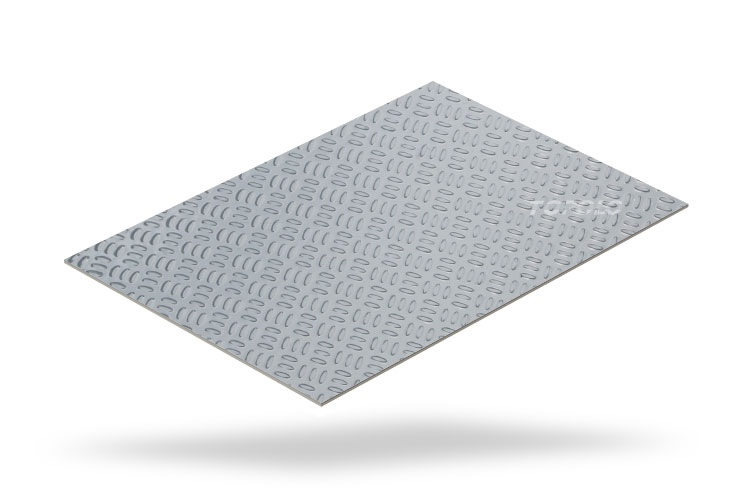

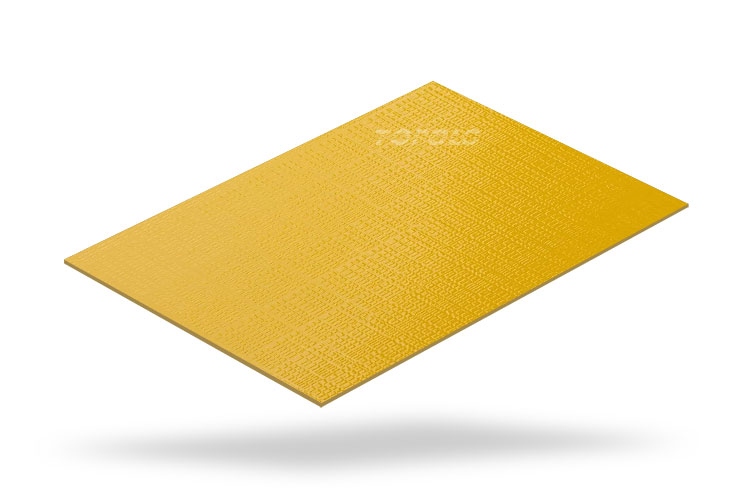

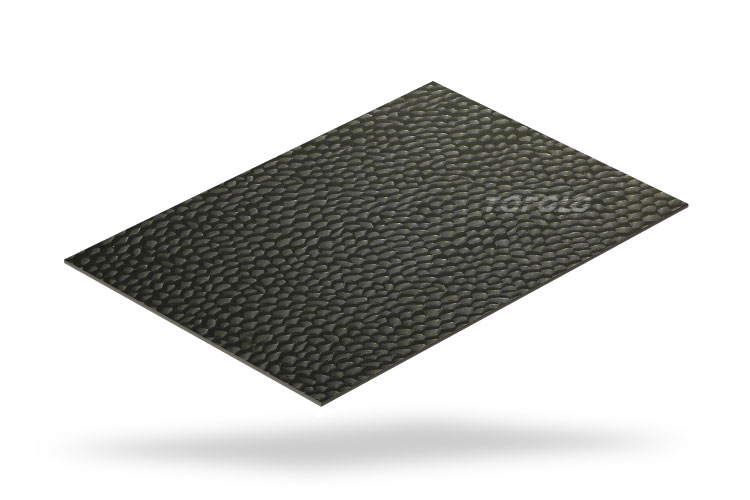

Surface Texture for FRP Sheets

The surface of FRP panels can be processed into various colors and textures to enhance the product’s external aesthetics. More

Application of Flat FRP Sheets

As a finishing material, flat fiberglass sheets are widely used in walls, ceilings, floors, or partitions due to their durability, lightness, and ease of cleaning. They are particularly popular in the construction of RVs, box trucks, enclosed trailers, mobile homes, cold rooms, insulated rooms, clean rooms, commercial kitchens, and other fields.

Leading FRP Sheet Manufacturer in China

TOPOLOGROUP is equipped with a continuous production line for wide, flat FRP panels. Roll widths of up to 3.2 meters are available, with thicknesses ranging from 0.7 to 5.0 mm, and lengths are unlimited. The product utilizes a blend of alkali-free glass fiber mat and age-resistant resin, resulting in excellent toughness and flexural strength. The FRP surface is finished with a high-end, age-resistant gel coat, with a thickness of up to 0.6 mm.

New Thermoplastic FRP Sheets

CFRT (Continuous Fiber Reinforced Thermoplastic) Sheet

- Tear-resistant

- Scratch-resistant

- Durable

- Recyclable

Different from thermosetting FRP sheets, thermoplastic FRP sheets with continuous fiber reinforcement are outstanding in the durability of the material. CFRT sheets are made of multiple layers of continuous fiber pre-impregnated unidirectional tapes laid at set angles (usually 0°, 90°). In addition, the number of layers of unidirectional tapes is determined according to the use requirements, usually 2-9 layers. This crisscrossing internal fiber structure is like a net, providing the sheet with an extremely high elastic modulus. CFRT sheets of the same thickness are far superior to thermosetting FRP sheets in physical properties such as compressive strength, tensile strength, shear strength, and bending strength. In addition, unlike thermosetting plastics that cannot be reused, CFRT, as a thermoplastic composite material, can be recycled, thereby reducing material waste and promoting sustainable economic development.

GRP/FRP Sandwich Panels

TOPOLOGROUP is also a professional sandwich panel manufacturer focusing on composite material solutions. It can produce FRP/GRP sandwich panels in various structural forms according to different application requirements, including lightweight and thermal insulating foam core panels, strong and durable plywood core panels, and high-strength and lightweight honeycomb core panels.