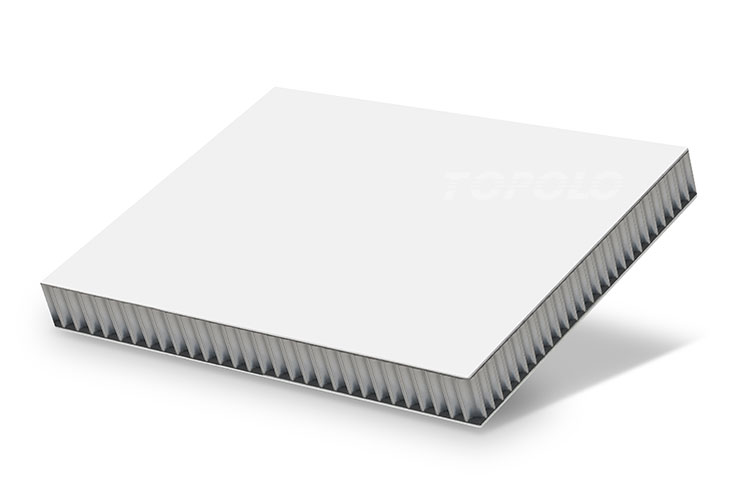

GRP/FRP Honeycomb Panels

Weather-resistant FRP Sheet + High Modulus Honeycomb Core

FRP honeycomb panels (also called GRP honeycomb panels) are lightweight yet strong composite panels. The core of these panels is made of PP (polypropylene) honeycomb, which provides excellent stiffness and strength while keeping weight low. The FRP (Fiberglass Reinforced Plastic) skins bonded to this core provide durability, corrosion resistance, and a smooth surface finish. It was created to replace traditional wood or metal panels and adapt to more application scenarios.

Product Features

Lightweight & High Strength

FRP honeycomb panels are a typical lightweight material providing extremely high strength-to-weight ratio.

Waterproof and moisture-resistant

It doesn’t rot like wood or rust like steel, and it maintains its structural stability in humid and rainy environments.

Structurally Stable

The hard texture of thermosetting FRP combined with the high modulus of polypropylene honeycomb can well maintain the stability of the panel structure and is not easy to bend or deform.

Weather resistance

FRP panels are added with anti-ultraviolet agents, which can withstand long-term exposure to strong ultraviolet rays without fading or decomposition.

Easy to clean

The surface of FRP is not easy to absorb dust, stains, etc., so it is very convenient to wash with water.

Specification of FRP Honeycomb Panels

| Facing | Thermosetting FRP Sheet. (Thickness: 0.7-5.0mm) |

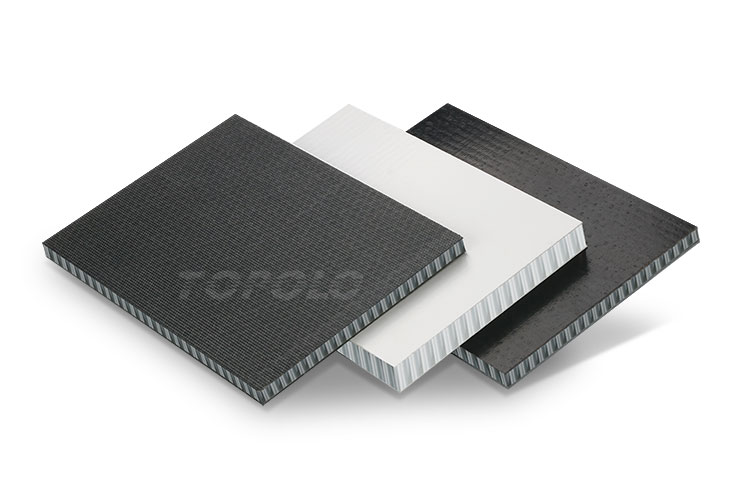

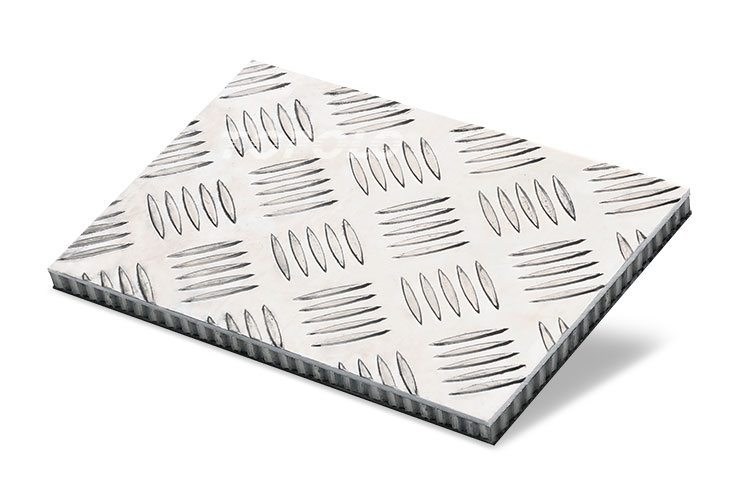

| Surface Treatment | Glossy, matte, embossed, rough, etc. |

| Surface Color | RAL series. (White, black, yellow, blue, brown, gray, etc.) |

| Core | PP (Polypropylene ) Honeycomb. (Density: 80-120kg/m³) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Thickness | 10-150mm. |

| Length | ≤12000mm. |

| Width | ≤3200mm. |

| Working Temperature | -40℃ to +80℃ |

Structural Diagram

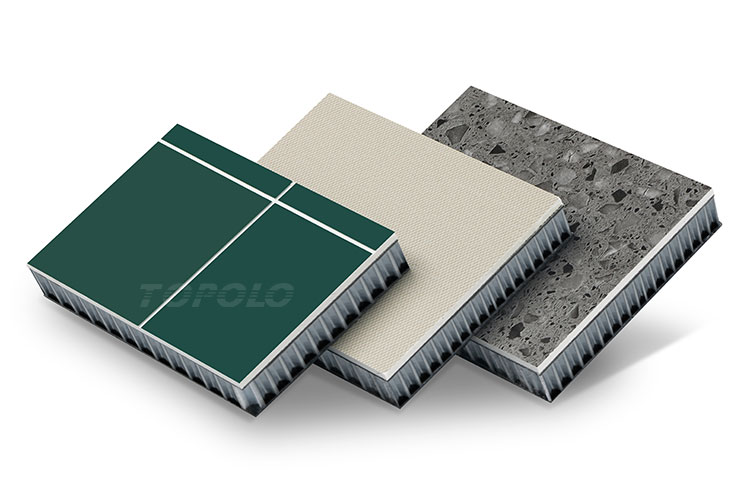

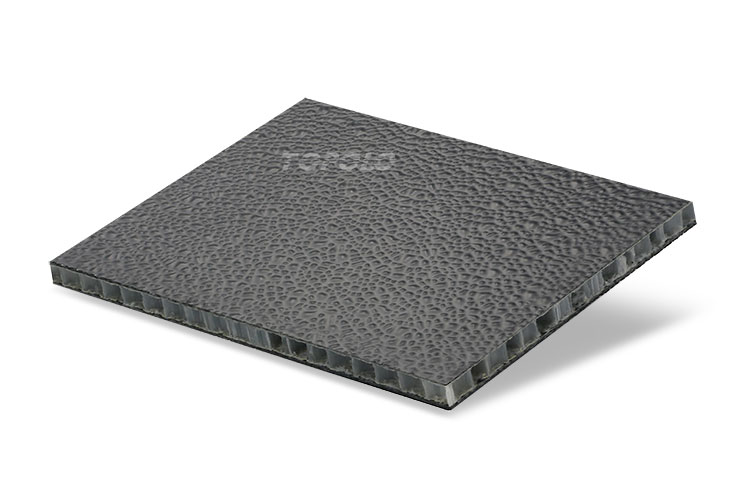

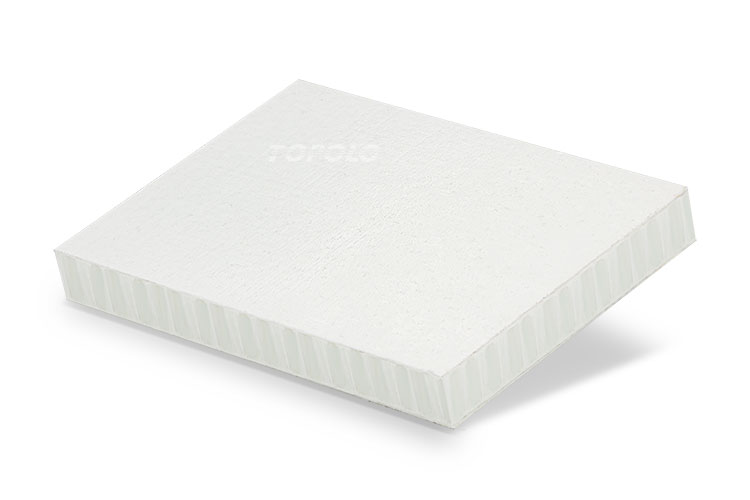

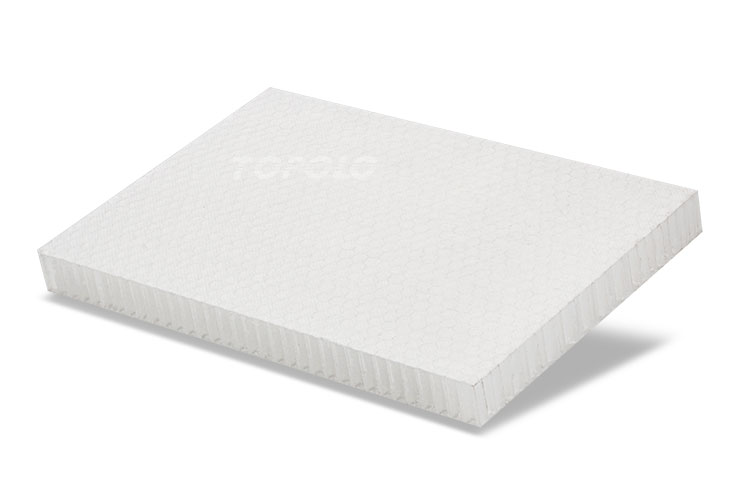

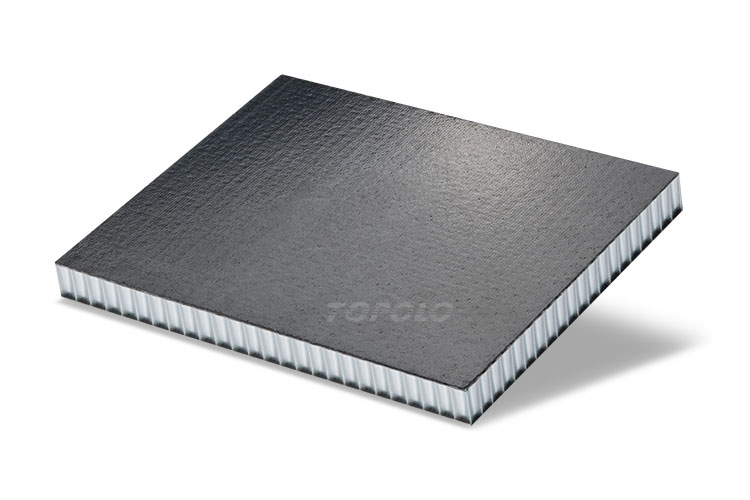

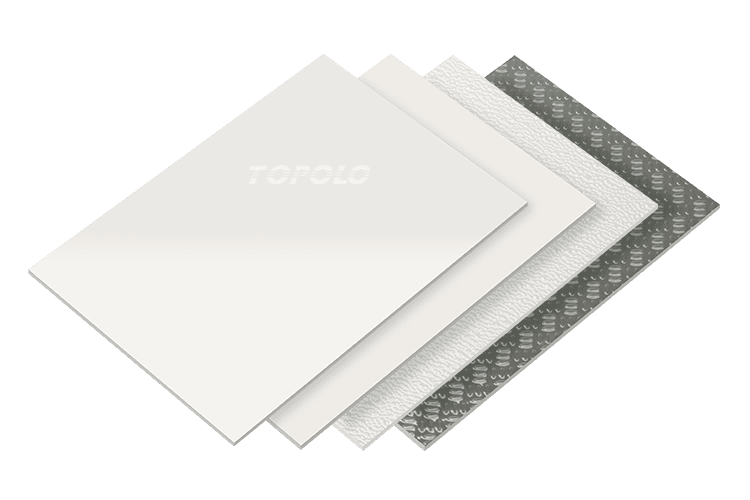

FRP Facing – Various Surface Styles

FRP(GRP) Sheet is a high-strength material made of glass fiber and resin matrix through a composite process. It has excellent characteristics such as light weight, high strength, corrosion resistance and aging resistance. Its surface can be processed into various styles, such as glossy, matte, non-slip, embossed, etc.

Common Performance parameters of FRP sheets

| Thickness | 1.0mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm |

| Weight(Kg/m2) | 1.5 | 2.25 | 3 | 3.75 | 4.5 |

| Glass content(%) | 19 | 25 | 29 | 30 | 30 |

| Tensile strength(Mpa) | 60 | 80 | 92 | 95 | 97 |

| Elongation at break(%) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Elastic modulus(Gpa) | 5.5 | 7 | 7.3 | 7.6 | 7.8 |

| Izod impact strength(KJ/m2) | 45 | 55 | 70 | 80 | 95 |

Lightweight Polypropylene Honeycomb Core

Polypropylene honeycomb is a lightweight, rigid thermoplastic used as the core of sandwich panel structures. Like aluminum honeycomb, it is also recyclable. Different honeycomb cell sizes have different densities and provide different mechanical strengths. Our honeycomb core is made of high modulus thermoplastic polypropylene plastic, which is flexible and not easily deformed.

Common Performance Parameters of Polypropylene Honeycomb Core

| Cell size(mm) | 8 | 10 | 12 |

| Density(kg/m³) | 80 | 75 | 70 |

| Compressive Strength(MPa) | 1.66 | 1.58 | 1.47 |

| Compressive Modulus(MPa) | 45.7 | 41.2 | 38.9 |

| Shear Modulus(MPa) | 0.50 | 0.45 | 0.40 |

| Operating Temperature(℃) | -40-80 | -40-80 | -40-80 |

| Thermal insulation U value | 2.2 | 2.2 | 2.2 |

Application of FRP Honeycomb Panels

FRP honeycomb panels are commonly used in various industries as wall panels, roof panels, partitions, floors, etc. Such as:

Our Customized Services

We are a professional FRP honeycomb panel manufacturer in China and provide customized services (customized size, thickness, surface color, and surface texture). Our factory is equipped with industry-leading composite panel production lines and adopts unique production processes to meet clients’ personalized design requirements.

- Extraordinary size customization

The size of the honeycomb composite panel can reach 12mx3.2m. (The current maximum size of the container is 40 feet (12.03 meters)

- One-piece vacuum composite process

The sandwich panel is laminated under high pressure in a vacuum environment. The surface of the panel after molding is flat and tightly combined, and the strength is far superior to the sandwich panel laminated in the air.

- High-precision machining

High-precision CNC processing can meet any personalized design needs and maintain the consistency of product precision.

To get more information about FRP honeycomb panels and find the perfect solution for your project, please contact us.