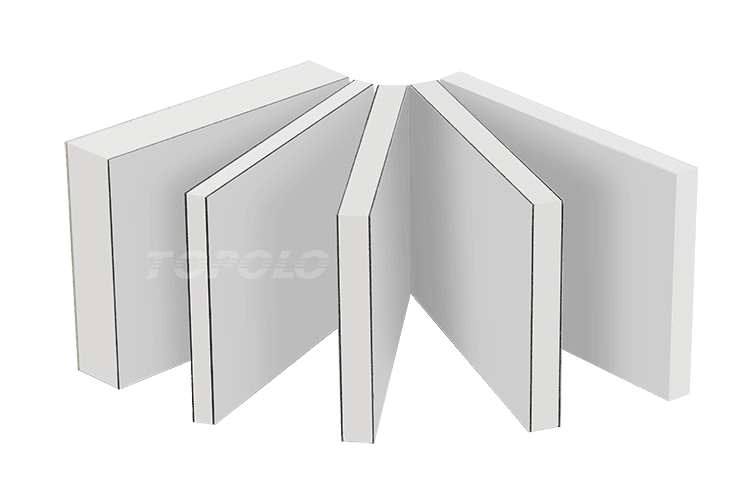

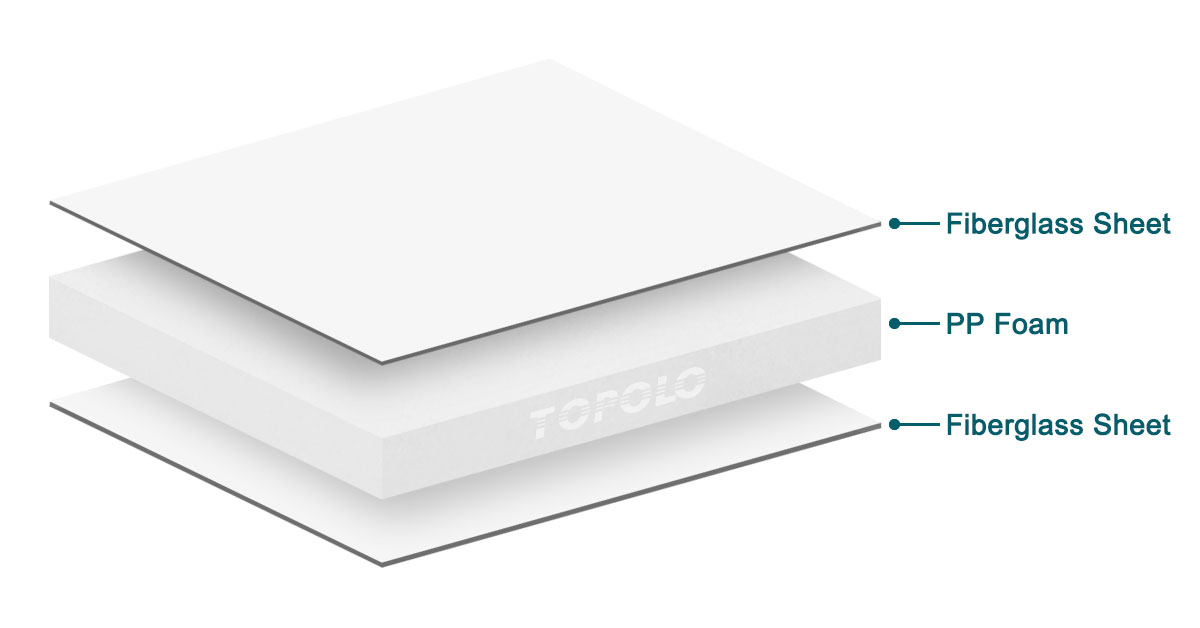

A fiberglass-reinforced plastic (FRP) skin is combined with a polypropylene (PP) foam core to create a high-strength, lightweight sandwich composite panel. This composite structure leverages the mechanical strength and impact resistance of FRP with the lightweight, thermal insulation, and energy-absorbing properties of PP foam, achieving a perfect combination of structural strength, functionality, and lightweight.

Advantages of Combining Fiberglass and PP Foam

☑ High Strength and Toughness

The FRP skin provides excellent impact and abrasion resistance, while the PP foam core absorbs impact energy, further enhancing the overall structural toughness and durability.

☑ Lightweight Design

The low-density PP foam significantly reduces the weight of the composite panel, helping to improve transportation efficiency, reduce fuel consumption, and increase the load-bearing capacity of modular buildings and vehicles.

☑ Thermal Insulation

The closed-cell structure of PP foam provides excellent thermal insulation for the composite panel.

☑ Waterproof and Corrosion-Resistant

The FRP skin offers excellent water-proof and corrosion-resistant properties, allowing it to withstand long-term use in humid or corrosive environments without deformation or damage.

☑ Processability and Environmental Protection

The composite panel can be cut, drilled, and thermoformed to meet customized requirements. Furthermore, PP foam is recyclable, complying with environmental requirements.

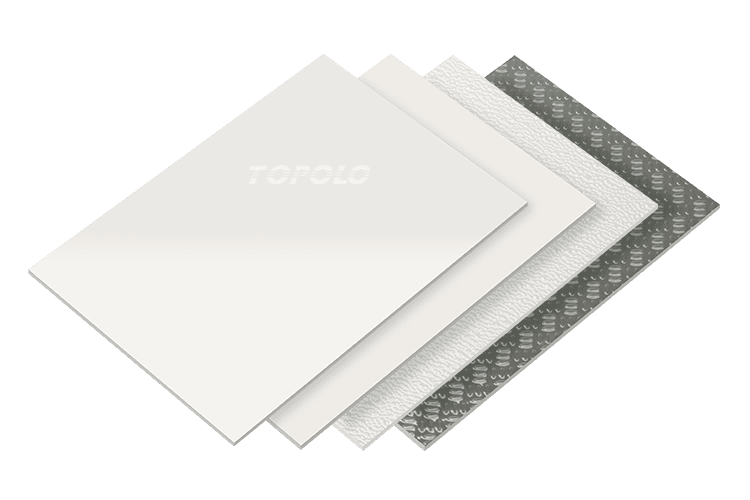

Types of FRP

- Irreversibly cross-linked through resin curing

- High strength and excellent rigidity

- Widely used in traditional high-strength composite panels

- Can be heat-formed and processed multiple times without damaging the fiber structure

- Impact- and tear-resistant, suitable for lightweight and recyclable composite panels

- More suitable for modular and removable structures

PP Foam Types for Composite Panels

- Low density, high toughness

- Excellent energy absorption

- Suitable for impact and shock absorption structures

- Homogeneous closed-cell structure

- High strength and deformation resistance

- Suitable for load-bearing and high-strength composite panels

- Can be molded into complex structures

- High impact and chemical resistance

- Suitable for customized panels and modular designs

Applications of Fiberglass PP Foam Sandwich Panels

This composite panel excels in lightweighting, durability, and functionality, making it an ideal material for modern transportation and modular mobile buildings.

- Reduce vehicle weight, improve fuel efficiency and load capacity.

- Provide thermal insulation, waterproofing, and lightweight wall and flooring.

Easy to transport and assemble, while providing strength, insulation, and waterproofing.

Get Your Custom Composite Panels

As one of the most dynamic fiberglass foam sandwich panel manufacturers in China, TOPOLOGROUP specializes in providing lightweight composite panel solutions. We produce a wide variety of foam-core composite panels to meet diverse application scenarios and functional requirements. With advanced production equipment, strict quality control and flexible customization capabilities, TOPOLOGROUP provides customers with reliable, durable and environmentally friendly composite panel solutions, making it your ideal composite panel partner.