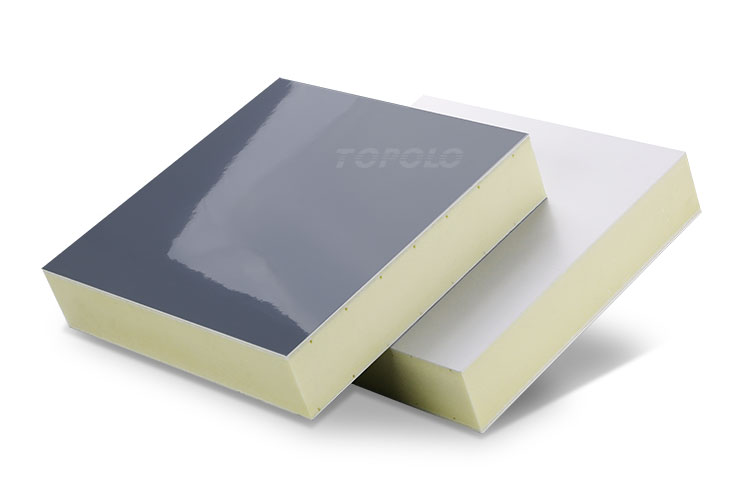

Coated Steel Skin XPS Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels » XPS Foam Sandwich Panels

- High strength

- Durability

- Affordable

Coated steel skin XPS foam sandwich panels are composed of coated steel skin as the surface layer and XPS (extruded polystyrene) foam as the core material. Due to its excellent performance, it has been widely used in construction, vehicles and other fields that have strict requirements on structural strength and thermal insulation.

Specifications

| Skin | GI (Galvanized steel) sheet. GL (Galvalume steel) sheet. PPGI (Pre-painted Galvanized) steel sheet. PPGL (Pre-painted Galvalume) steel sheet. |

| Core | XPS (Extruded Polystyrene) foam. (Density: 35-50kg/m³) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Thickness | 10-150mm. |

| Length | ≤12000mm. |

| Width | ≤1500mm. |

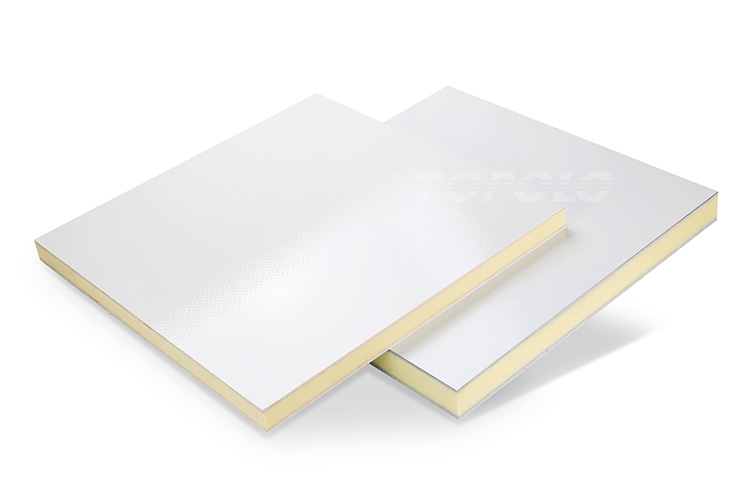

Structural Diagram

Galvanized steel skin sandwich panels

Pre-painted steel skin sandwich panels

100% virgin XPS foam core

XPS foam is a lightweight closed-cell foam with excellent thermal insulation, waterproofness, moisture resistance, and compression resistance. It is an ideal choice for manufacturing high-performance composite panels.

- The cells are densely packed, uniform, and of uniform size.

- The color is uniform and bright.

- The surface is smooth and resistant to breakage.

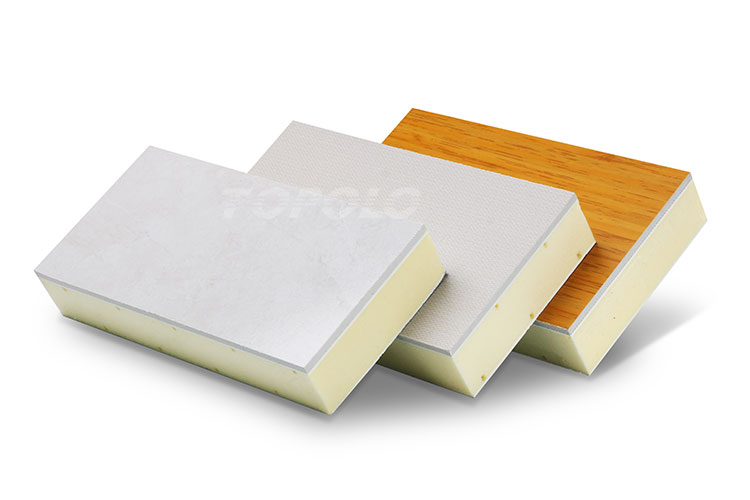

Coated steel types

- GI, GL sheet

Galvanized steel is renowned for its exceptional corrosion resistance and durability. It’s a process in which hot-rolled or cold-rolled steel is coated with a layer of zinc or aluminum-zinc to protect it from rust. This coating is typically applied through a process called hot-dip galvanizing, where the steel is immersed in molten zinc or a mixture of aluminum and zinc. Steel coated with a mixture of zinc (Zn) and aluminum (Al), known as galvalume steel, offers superior corrosion resistance compared to traditional galvanized steel, especially under high temperatures and harsh environmental conditions.

Performance Parameters

| Thickness | 0.2mm – 6.0mm |

| Width | 600mm – 1500mm |

| Zinc Coating Weight | Z40, Z60, Z80, Z100, Z120, Z180, Z275 |

| Spangle Types | Normal Spangle; Minimized Spangle; No Spangle |

| Tensile Strength | 270-500 MPa |

| Yield Strength | 140-360 MPa |

- PPGI, PPGL sheet

PPGI (pre-painted galvanized steel) or PPGL (pre-painted galvanized steel) is a GI or GL steel sheet that has been pre-treated and then coated with one or more layers of organic paint, which is then baked and cured. This improves the aesthetics and weather resistance of the GI or GL steel sheet. This ensures the sheets can withstand harsh environmental conditions, including moisture, UV radiation and physical wear and tear.

Performance Parameters

| Thickness | 0.2mm – 6.0mm |

| Width | 600mm – 1500mm |

| Zinc Coating Weight | Z40, Z60, Z80, Z100, Z120, Z180, Z275 |

| Spangle Types | Normal Spangle; Minimized Spangle; No Spangle |

| Tensile Strength | 270-500 MPa |

| Yield Strength | 140-360 MPa |

| Surface Coating | Polyester (PE), polyvinylidene fluoride (PVDF) |

| Color | RAL color series |

Common Applications

Refrigeration equipment

- Used in refrigerated vehicles and cold storage equipment to keep the goods at the required temperature during transportation and storage.

Modular Buildings

- Wall panels, roof panels, and partitions for commercial buildings, industrial facilities, and residential structures.

Industrial facilities

- Cleanrooms, food processing plants, and pharmaceutical plants—these places have stringent requirements for hygiene, insulation, and ease of cleaning.

Agricultural buildings

- Barns, greenhouses, and livestock sheds require insulation to regulate interior temperatures and protect livestock or crops.

We also produce coated steel sandwich panels with PU (polyurethane), PET (polyethylene terephthalate), and PVC (polyvinyl chloride) foam cores. Please contact us for more information.