Coated Steel Skin PU Foam Sandwich Panels

High-strength modular building wall panels

Home » Materials » Foam Sandwich Panels » PU Foam Sandwich Panels

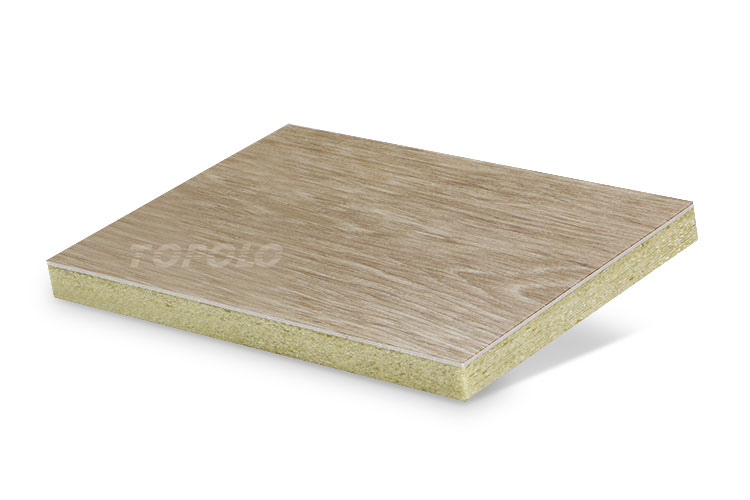

Coated steel skin polyurethane foam sandwich panels, a new building wall material that combines high strength and versatility, are gaining increasing popularity in modern architecture. Their unique “sandwich” structure—combining coated steel skins with a polyurethane foam core—achieves a unique combination of structural strength, thermal insulation, and fire resistance, making them an ideal choice for industrial plants, warehouses, logistics facilities, and mobile buildings.

Specifications

Structural Diagram

PU Foam Core

- Density: 28-50kg/m³.

- Thermal conductivity: ≤0.024W/(m.k).

- Bonding strength: ≥100kPa.

- Rate of dimensional change(70ºCx48h): 1mm.

- Compressive strength: ≥160kPa.

- Tensile strength: ≥205kPa.

- Elongation at break: ≥10%.

- Porosity by closed pore: ≥92%.

- Water absorption: ≤3%.

- Water vapor permeability; ≤5Hg/(Pa.m.s).

- Anti-permeability(1000mmx24h)(1000mm water column X24h hydrostatic pressure): ≤5mm.

Coated steel types

- GI, GL sheet

Galvanized steel is renowned for its exceptional corrosion resistance and durability. It’s a process in which hot-rolled or cold-rolled steel is coated with a layer of zinc or aluminum-zinc to protect it from rust. This coating is typically applied through a process called hot-dip galvanizing, where the steel is immersed in molten zinc or a mixture of aluminum and zinc. Steel coated with a mixture of zinc (Zn) and aluminum (Al), known as galvalume steel, offers superior corrosion resistance compared to traditional galvanized steel, especially under high temperatures and harsh environmental conditions.

Performance Parameters

| Thickness | 0.2mm – 6.0mm |

| Width | 600mm – 1500mm |

| Zinc Coating Weight | Z40, Z60, Z80, Z100, Z120, Z180, Z275 |

| Spangle Types | Normal Spangle; Minimized Spangle; No Spangle |

| Tensile Strength | 270-500 MPa |

| Yield Strength | 140-360 MPa |

- PPGI, PPGL sheet

PPGI (pre-painted galvanized steel) or PPGL (pre-painted galvanized steel) is a GI or GL steel sheet that has been pre-treated and then coated with one or more layers of organic paint, which is then baked and cured. This improves the aesthetics and weather resistance of the GI or GL steel sheet. This ensures the sheets can withstand harsh environmental conditions, including moisture, UV radiation and physical wear and tear.

Performance Parameters

| Thickness | 0.2mm – 6.0mm |

| Width | 600mm – 1500mm |

| Zinc Coating Weight | Z40, Z60, Z80, Z100, Z120, Z180, Z275 |

| Spangle Types | Normal Spangle; Minimized Spangle; No Spangle |

| Tensile Strength | 270-500 MPa |

| Yield Strength | 140-360 MPa |

| Surface Coating | Polyester (PE), polyvinylidene fluoride (PVDF) |

| Color | RAL color series |

Materials and Craftsmanship

- Weather-resistant coated steel skin.

- Highly insulating polyurethane foam.

- High-temperature resistant waterproof adhesive.

- One-piece composite sandwich panel manufacturing process.