CFRT Skin XPS Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels » XPS Foam Sandwich Panels

New FRP/GRP composite materials

New Trends in Glass Fiber Reinforced Composite Panels

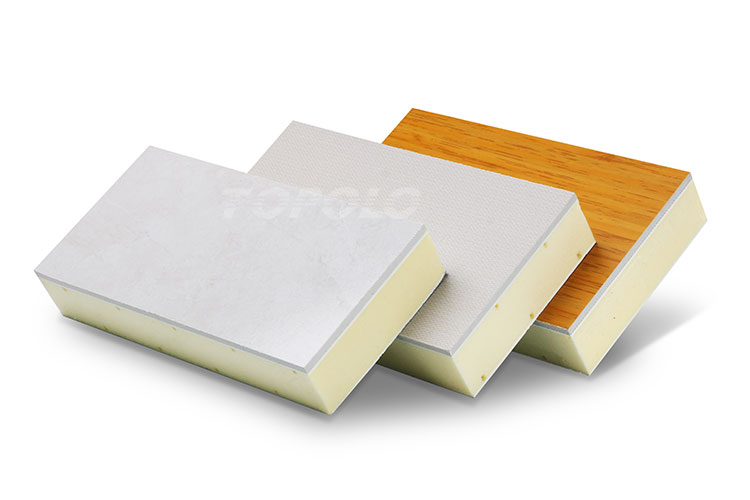

The CFRT skin XPS foam sandwich panel is a new thermal insulation composite panel developed by TOPOLOGROUP for vehicle bodies. It consists of two layers of CFRT (continuous fiber reinforced thermoplastic) sheets, an XPS foam core, and several frame materials. As an alternative to thermosetting FRP/GRP foam core sandwich panels, it offers equivalent functionality and, in some cases, surpasses them.

Using thermoplastic CFRT instead of thermosetting FRP as the surface layer of the XPS foam sandwich panel can bring many benefits.

Specifications

Schematic Diagram

Details

About CFRT surface treatment

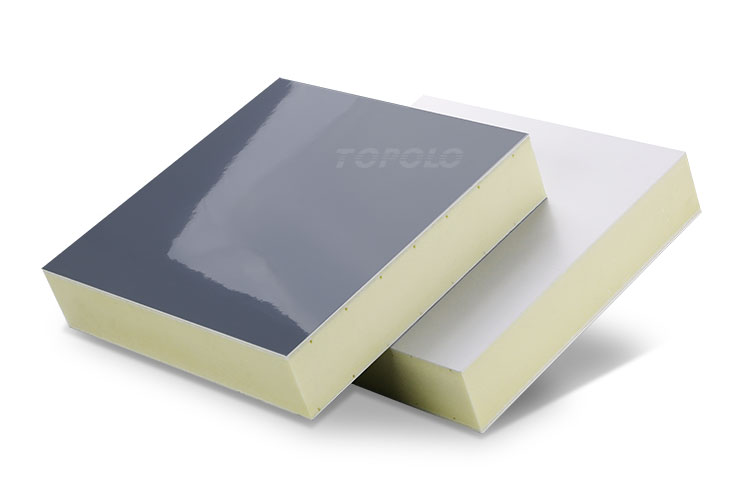

- Features: The surface of CFRT is covered with a polymer protective film, which makes its surface smooth and flat, achieving a glossy effect comparable to gel-coated FRP or metal panels.

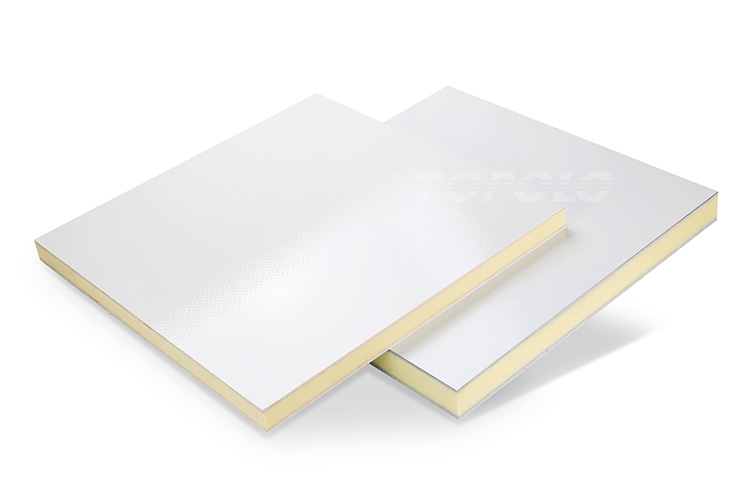

- Features: There is no coating on the surface of CFRT, showing the polypropylene resin itself, and the surface is relatively rough.

How to Enhance the Strength of CFRT Skin Foam Sandwich Panels

Although CFRT sheets possess excellent mechanical strength, to compensate for the inherent limitations of the XPS foam core and improve the panel’s resistance to deformation, a common practice is to embed a “skeleton” material (such as wood, composite materials, or metal) within the panel to provide structural support, thereby meeting the manufacturing requirements for larger, higher-strength panels.

Common Applications

CFRT skin XPS foam sandwich panels are used to build insulated box bodies to provide continuous and stable thermal insulation and safety protection.

Cargo vehicle bodies

- Refrigerated trucks.

- Refrigerated trailers.

- Portable trailers.

- Ambulance boxes.

- Livestock transporters.

- Poultry transporters, etc.

Camping RV bodies

- Expedition trucks.

- Off-road trailers.

- Truck campers.

- Caravans, etc.

Production and Processing

- The foam sandwich panels, laminated under high pressure, have a smooth surface and are tightly bonded.

- Fast, high-precision panel processing on a machining platform, including edge trimming, cutting, drilling, and polishing.

If you are interested in the composite panel, please tell us your application requirements and we will customize the solution that best suits your project.