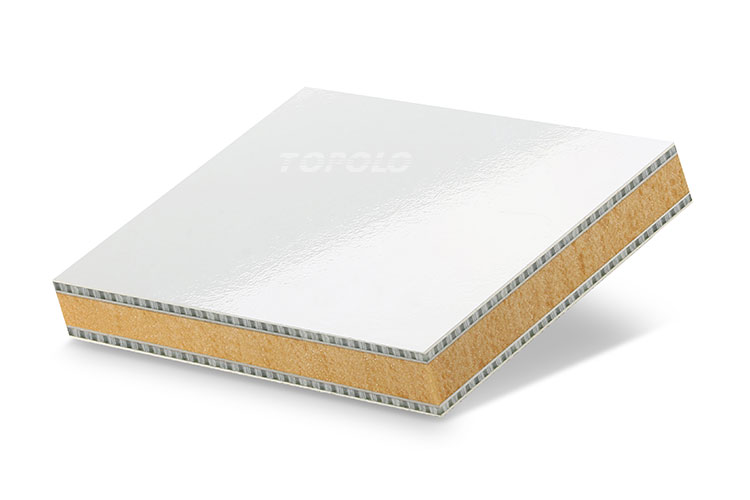

CFRT Skin PVC Foam Sandwich Panels

More durable foam sandwich panels

Home » Materials » Foam Sandwich Panels » PVC Foam Sandwich Panels

- Lightweight

- High strength and durability

- Corrosion and moisture-proof

- Thermal insulation

- Flame resistant

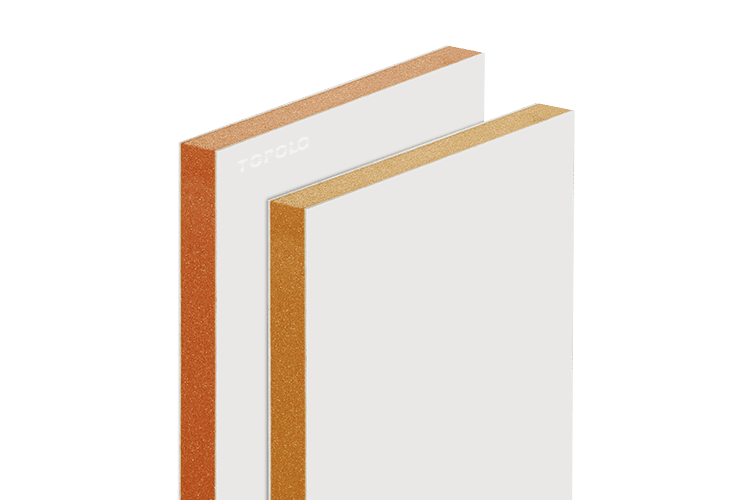

The material is a composite of rigid PVC foam and CFRT (continuous fiber reinforced thermoplastic). CFRT is used instead of thermosetting FRP (glass fiber reinforced plastic) to achieve a more durable and strong sandwich panel structure.

Specifications

| Facing | CFRT(Continuous Fiber Reinforced Thermoplastic ) composite sheet. (Thickness: 0.7-2.0mm or Customized) |

| Surface Treatment | Glossy, matte, embossed, rough. |

| Core | PVC (Polyvinyl Chloride) foam. (Density: 40-250kg/m³) |

| Composite Method | Thermoplastic lamination or adhesive lamination. |

| Thickness | 10-150mm or Customized. |

| Length | ≤12000mm. |

| Width | ≤2800mm. |

Structural Diagram

Outer Layer – CFRT Sheets

Continuous fibers are combined with thermoplastic resins to create durable, lightweight and durable UD prepreg tapes, which are then thermal laminated together at set angles to form CFRT sheets with improved performance. CFRT laminates are known for their excellent mechanical properties, including high strength-to-weight ratio, good impact resistance, and resistance to environmental factors such as moisture and chemicals.

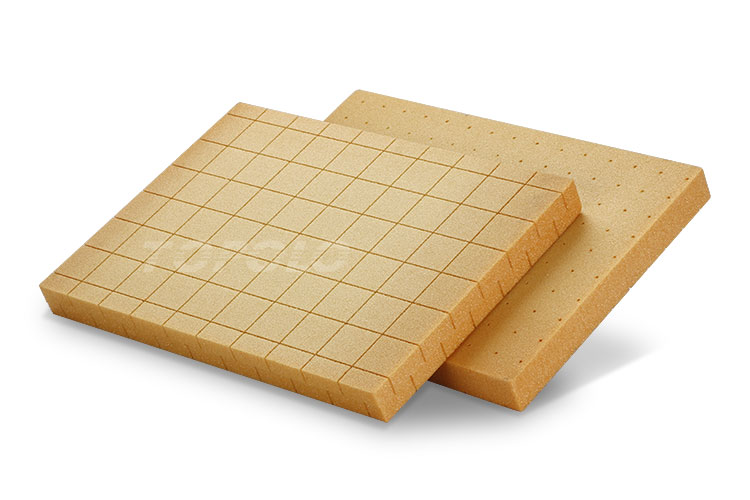

Closed-cell PVC Foam Core

Closed-cell PVC foam is a rigid material with a closed cell structure. Due to its low thermal conductivity and unique honeycomb structure, it performs better than other rigid foams (XPS, PU, PET, EPS) in terms of structural strength, thermal insulation, waterproofing and other properties, and has a balanced overall performance.

PVC Foam Performance Parameters

| Item | P60 | P80 | P100 | P130 | P200 | P250 |

| Density ( kg/m3) | 60 | 80 | 100 | 130 | 200 | 250 |

| Tensile Strength(Mpa) | 1.8 | 2.5 | 3.5 | 4.8 | 7.1 | 9.2 |

| Tensile Modulus(Mpa) | 75 | 95 | 130 | 175 | 250 | 320 |

| Compressive Strength(Mpa) | 0.9 | 1.4 | 2.0 | 3.0 | 4.8 | 6.2 |

| Compressive Modulus(Mpa) | 72 | 90 | 135 | 170 | 240 | 300 |

| Shear Strength(Mpa) | 0.76 | 1.15 | 1.6 | 2.2 | 3.5 | 4.5 |

| Shear Mpdulus(Mpa) | 20 | 27 | 35 | 50 | 85 | 104 |

| Shear Strain(%) | 20 | 30 | 40 | 40 | 40 | 40 |

Application of CFRT Skin PVC Foam Sandwich Panels

CFRT skin PVC foam sandwich panels are used in applications that require lightweight and high strength, such as truck bodies, RVs, marine, building, and other demanding industries.

- Truck Bodies and Trailers: For dry freight, refrigerated transport, and specialized vehicles.

- RV Composite Panels: For body construction of motorhomes, caravans, expedition trucks, truck campers, hardshell roof tents, teardrop trailers, off-road trailers, etc.

- Modular Buildings: Walls, floors, ceilings, partitions, etc.

- Boxes: aviation box, industrial and agricultural equipment shell, etc.

We also offer CFRT sandwich panels with PU (Polyurethane), PET (Polyethylene Terephthalate) and XPS (Extruded Polystyrene) foam cores. For more information on composite materials, please contact us.