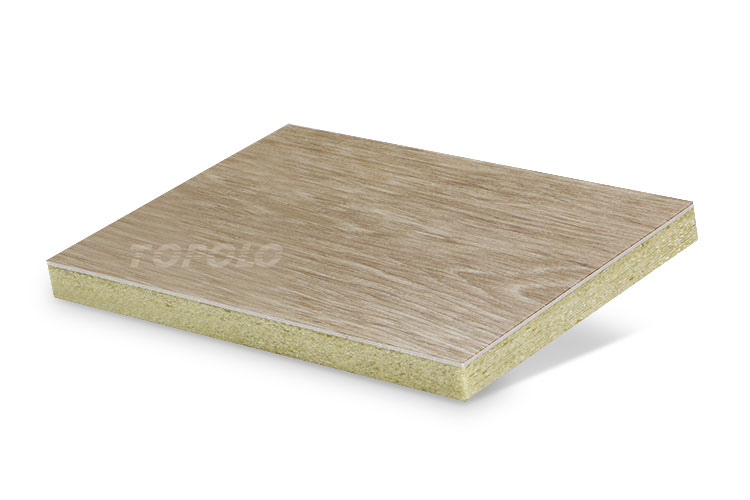

CFRT Skin PU Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels » PU Foam Sandwich Panels

New thermal insulation fiberglass composite panels

- Lightweight

- High Strength

- Thermal Insulation

- Weather Resistant

- Affordable

This composite material combines closed-cell polyurethane (PU) foam with continuous fiber-reinforced thermoplastic (CFRT) sheets via an adhesive. It combines the high strength and toughness of CFRT with the thermal insulation properties of polyurethane foam. It can replace thermoset FRP, aluminum, and steel skin foam sandwich panels in many applications. In addition to its excellent mechanical properties and weather resistance, large-scale application of this composite panel can significantly reduce budget costs.

CFRT skin PU foam sandwich panels are a major breakthrough in the application of thermal insulation materials. TOPOLOGROUP overcomes the problem of easy delamination of PU foam composite sandwich panels. The PU foam core is tightly combined with the CFRT surface layer, the structure is stable, and it can withstand extreme high temperature and high humidity environments. The panel surface adopts a unique anti-aging treatment to effectively resist ultraviolet rays and extend the service life.

Specifications

| Facing | CFRT – Continuous Fiber Reinforced Thermoplastic. (Thickness: 0.7-2.0mm or Customized) |

| Surface Treatment | Matte/Glossy/Rough. |

| Core | PU (Polyurethane) foam. (Density: 28-50kg/m³) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Thickness | 10-150mm. |

| Length | ≤12000mm. |

| Width | ≤2800mm. |

| Frame Materials | Timbers, composite profiles, etc. |

| Working Temperature | -40°C to 80°C |

Schematic Diagram

PU Foam Core

- Density: 28-50kg/m³.

- Thermal conductivity: ≤0.024W/(m.k).

- Bonding strength: ≥100kPa.

- Rate of dimensional change(70ºCx48h): 1mm.

- Compressive strength: ≥160kPa.

- Tensile strength: ≥205kPa.

- Elongation at break: ≥10%.

- Porosity by closed pore: ≥92%.

- Water absorption: ≤3%.

- Water vapor permeability; ≤5Hg/(Pa.m.s).

- Anti-permeability(1000mmx24h)(1000mm water column X24h hydrostatic pressure): ≤5mm.

CFRT skin

- Composition: 2-3 layers of thermoplastic unidirectional tape.

- Glass fiber content: 60-70%.

- Fiber type: Continuous glass fiber.

- Resin type: Thermoplastic polypropylene resin.

- Thickness: 0.7-2.0mm.

- Surface treatment (optional): Polymer film (glossy/matte).

CFRT surface treatment

- There is no protective film on the CFRT surface, which retains the natural color of the thermoplastic unidirectional tape and has a relatively rough surface.

- A polymer film is laminated on the surface of natural color CFRT. These films make the CFRT surface smooth and flat and greatly improve the aesthetics.

- The black CFRT surface is laminated with a polymer film, so its color is darker.

Structural Reinforcement and Performance Improvement

We know that PU foam is fragile and easily damaged. Relying solely on it as the core material for sandwich panels is insufficient to withstand higher strength challenges or meet the demands of diverse applications. Increasing the thickness of the foam core and skin to enhance structural strength is impractical. A common approach is to add a “skeleton” to the foam core. The unique feature of PU foam sandwich panels is that this “skeleton” is made of non-metallic, low-thermal-conductivity materials, such as waterproof wood and composite profiles. This ensures structural strength while also avoiding heat transfer issues.

Applications

CFRT skin PU foam sandwich panels are gradually replacing traditional metal sandwich panels and becoming the preferred material for refrigerated trucks, trailer boxes and insulated building wall panels.

Such as:

- Refrigerated truck bodies.

- Refrigerated trailers.

- Ice cream truck bodies.

- Clean rooms.

- Ice fishing trailers.

- Cryotherapy rooms.

- Caravans.

- Mobile cold storage rooms.

- Mobile homes.

- Mobile shelters.

- Industrial equipment housings.

- Insulated farmhouses, etc.

Production and Processing

We are a professional foam core composite panel manufacturer in China, leading the way in both product quality and production capacity in China.

- Professional material experts customize reliable solutions for each client’s project

- All raw materials are tested through multiple processes to meet production standards.

- Leading thermoplastic composite sheet production line.

- High-precision five-axis CNC machining can meet high-standard post-processing needs.

In addition, we also produce CFRT sandwich panels with XPS (Extruded Polystyrene), PET (Polyethylene Terephthalate), and PVC (Polyvinyl Chloride) foam cores. For more product information, please contact us.