CFRT SHEETS

Home » Materials » Fiber Reinforced Composites

Continuous fiber reinforced thermoplastic laminated composite sheets

Lighter, stronger, more durable and more eco-friendly.

What is CFRT Sheet?

Continuous fiber-reinforced thermoplastic (CFRT) laminates are an advanced, lightweight composite material that is an upgrade from thermoplastic prepreg unidirectional tape. Continuous fibers are combined with thermoplastic resins to create durable, lightweight and durable prepreg tapes, which are then thermal laminated together at set angles to form CFRT sheets with improved performance. CFRT laminates are known for their excellent mechanical properties, including high strength-to-weight ratio, good impact resistance, and resistance to environmental factors such as moisture and chemicals. In addition, unlike thermosetting plastics that cannot be reused, as a thermoplastic composite material, CFRT is recyclable, reducing material waste and contributing to the sustainable development of the economy.

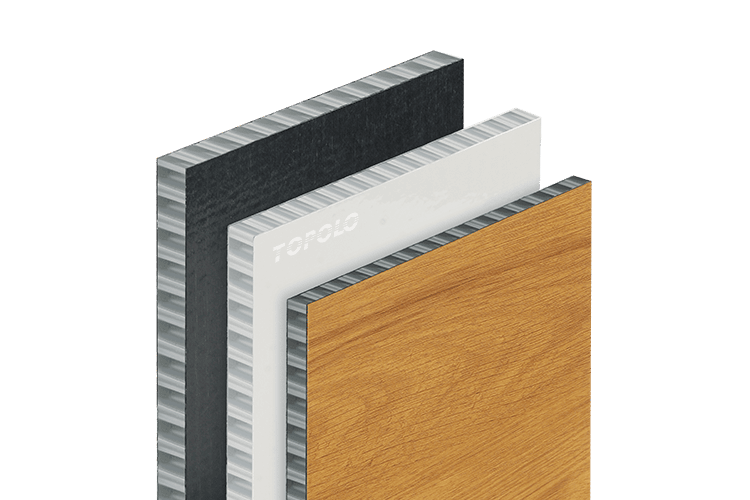

Thermoplastic Composite Laminate Structure

The characteristics of continuous fibers give thermoplastic unidirectional tapes excellent tensile strength in the fiber direction, but they are also very easy to tear in this direction. When thermoplastic unidirectional tapes are laid at different angles, they will improve mechanical properties in multiple directions, whether it is compression strength, tensile strength, shear strength or bending strength. The more layers of unidirectional prepreg tape, the higher its mechanical properties. Depending on its application requirements, up to ten layers or even more can be reached. However, the more layers, the better the performance. This requires a series of performance tests and demonstrations to select the most suitable and economical number of layers.

Specifications

| Cross-layer Number | 2-9 layers or customized. |

| Cross-ply Angle | 90°/0°. |

| Fiber Type | Continuous glass fiber. Continuous carbon fiber. |

| Fiber Content | 50% – 70%. |

| Resin Types | PP(Polypropylene). |

| PPS(Polyphenylene Sulfide). | |

| PE (Polyethylene). | |

| PA (Polyamide). | |

| PEI (Polyetherimide). | |

| PC (Polycarbonate). | |

| PEEK(polyetheretherketone). | |

| PET (Polyethylene Terephthalate). | |

| PSU (Polysulfone). | |

| Color | Black, white, natural or RAL series. |

| Surface Treatment | Laminated film (glossy/matte). Embossing (anti-slip) |

| Total Thickness | 0.7-2.0mm or customized. |

| Sheet Width | ≤2800mm. |

| Length | Roll: 200-500m/roll. Sheet: ≤12m. |

Applications of CFRT Sheets

CFRT sheets are used in applications that require lightweight processing while maintaining high-strength mechanical properties, and their role in economic development is becoming increasingly important.

CFRT sheets are used in automotive components, leveraging their high strength and lightweight properties to reduce vehicle weight. Such as:

- Doors

- Seat frames

- Bumpers

- Underbody skid plates, etc.

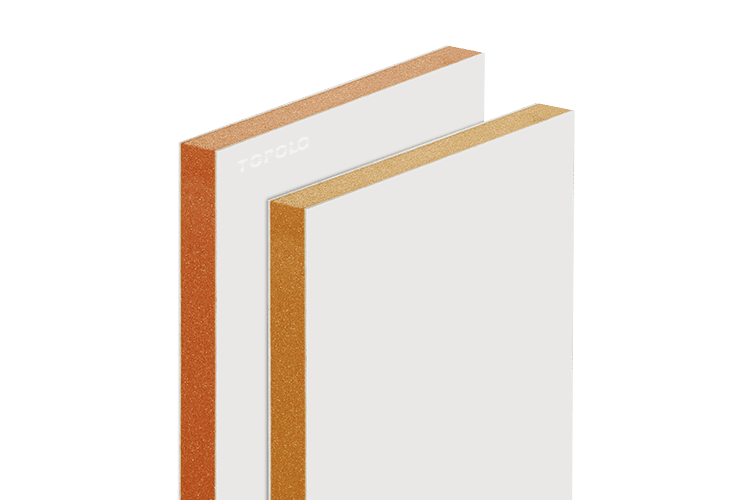

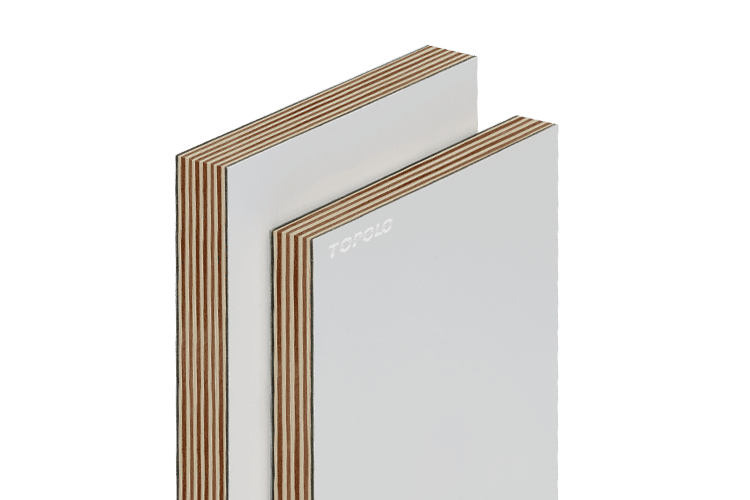

CFRT sheets are used as skins for honeycomb sandwich panels, foam sandwich panels, and plywood panels, which can be used to build lightweight and durable box bodies. Such as:

- Refrigerated box.

- Dry cargo box.

- Ambulance box, etc.

CFRT sheets, due to their excellent strength, durability, and lightweight properties, have become an important material for manufacturing aircraft components, reducing aircraft weight. Such as:

- Fuselage.

- Wings.

- Floor, etc.

- CFRT sheets are lightweight and high-strength, making them a great aerodynamic material. They are used in skirts and tails for vehicles, boats, and aircraft, guiding airflow, reducing wind resistance, and increasing speed and endurance.

- CFRT sheets are being used as roofs, walls, and floors in buildings, replacing metal or wood, and are being widely adopted in industry, agriculture, and animal husbandry.

- CFRT sheets are used to manufacture high-performance sports equipment such as skateboard shells and pickleball paddles.

Leading CFRT Sheet Manufacturer China

TOPOLOGROUP is a leading manufacturer of continuous fiber-reinforced thermoplastic composite sheets in China, providing proven composite sheet solutions for a wide range of industries. We also produce CFRT composite panels (honeycomb core, foam core, and plywood core).

- Advanced Equipment: Our fully automated thermoplastic composite lamination line can laminate 2-10 layers of thermoplastic prepreg unidirectional tape at a time.

- Efficient Production: Daily output reaches thousands of square meters.

- High Specifications: CFRT sheets are available in widths up to 2.8 meters and thicknesses ranging from 0.7 to 10 mm.

CFRT Sheets – New FRP/GRP Sheets

Polypropylene resin fiberglass CFRT sheet is a lighter and more durable FRP (fiberglass reinforced plastic) sheet that can replace thermosetting FRP sheet, aluminum sheet and other materials as the skin material of composite panels.

- By coating high-performance decorative films, it can get a smoother and flatter surface.

- By bonding a layer of spun-bond non-woven fabric, it can be better composited with other material systems, such as foam, honeycomb core, plywood, etc.

- It can be composited with thermoplastic materials without the use of adhesives by the thermoplastic composite lamination process.

Common Surface Treatment for CFRT Sheets

CFRT sheets can be embossed for superior anti-slip properties or coated with a protective film for a more decorative finish.

CFRT Sandwich Panels

To get more information about our continuous fiber reinforced thermoplastic laminates and get professional solutions, please consult us.