Specification

| CFRT Sheet | Fiber Type: Continuous Glass Fiber. | |

| Resin Type: Thermoplastic Polypropylene. | ||

| Fiber Content: 60-75%. | ||

| Density: 1.54-1.63 g/cm³. | ||

| Thickness: 0.7-2.0mm or customized. | ||

| Unidirectional Tape Layers: 2-9. | ||

| Surface Treatment (Optional) | Matte/Glossy protective film. | |

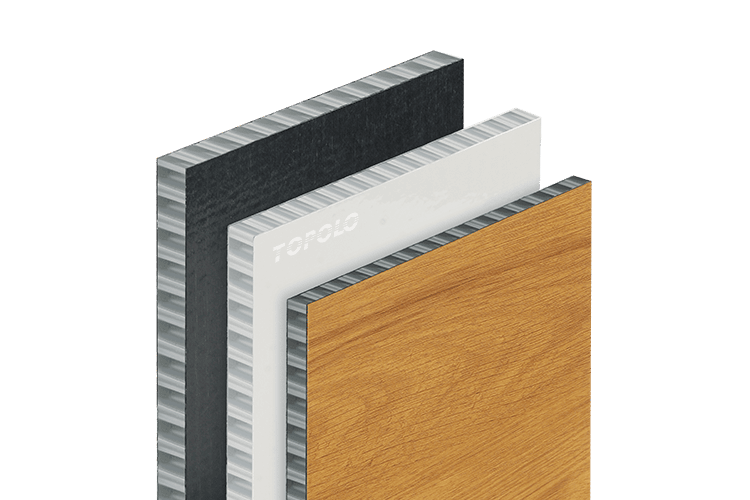

| Core Material & Composite Method | Thermal Composite | PET (Polyethylene terephthalate) foam. (Density: 60-300kg/m³. |

| PP (Polypropylene ) Honeycomb. (Density: 80-120kg/m³). | ||

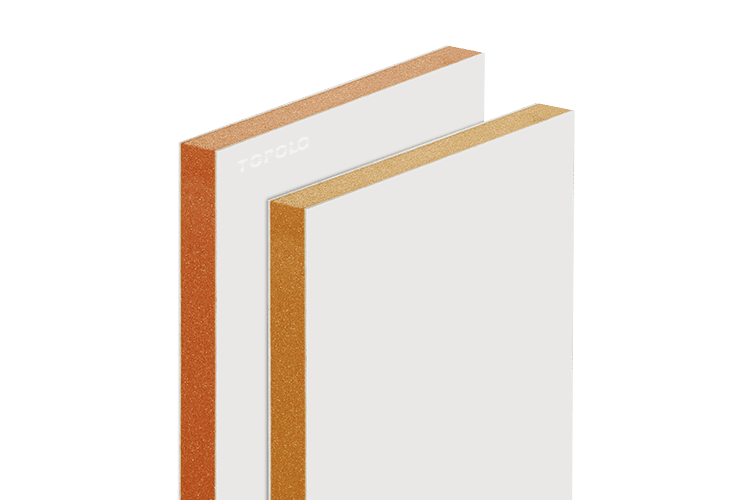

| Adhesive bonding | XPS (Extruded Polystyrene) foam. (Density: 35-50kg/m³). | |

| PU (Polyurethane) foam. (Density: 28-50kg/m³). | ||

| PVC (Polyvinyl Chloride) foam. (Density: 40-250kg/m³). | ||

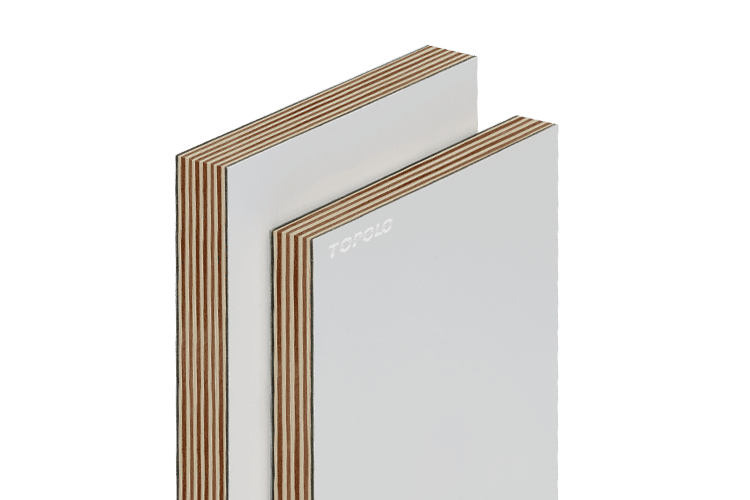

| Plywood. (Birch, pine, poplar, eucalyptus, oak, etc). | ||

| Panel Thickness | 5.0-150mm. | |

| Pane Length | ≤12000mm. | |

| Pane Width | ≤2800mm. | |

CFRT – Continuous Fiber Reinforced Thermoplastic

Continuous fiber reinforced thermoplastic (CFRT) laminate sheets are an advanced lightweight composite material. Continuous fibers are combined with thermoplastic resins to create durable, lightweight and durable prepreg tapes, which are then thermal laminated together at set angles to form CFRT sheets with improved performance.

CFRT – Thermosetting FRP Alternative

- Lightweight.

- High modulus.

- Durable.

- Recyclable.

- Low-cost.

The purpose of developing CFRT sheets is to replace some applications of thermosetting FRP sheets, achieve better performance and reduce manufacturing costs, and achieve better economic benefits and environmental protection. CFRT laminate sheets are known for their excellent mechanical properties, including high strength-to-weight ratio, good impact resistance, and resistance to environmental factors such as moisture and chemicals. In addition, unlike thermosetting plastics that cannot be reused, as a thermoplastic composite material, CFRT is recyclable, reducing material waste and contributing to the sustainable development of the economy.

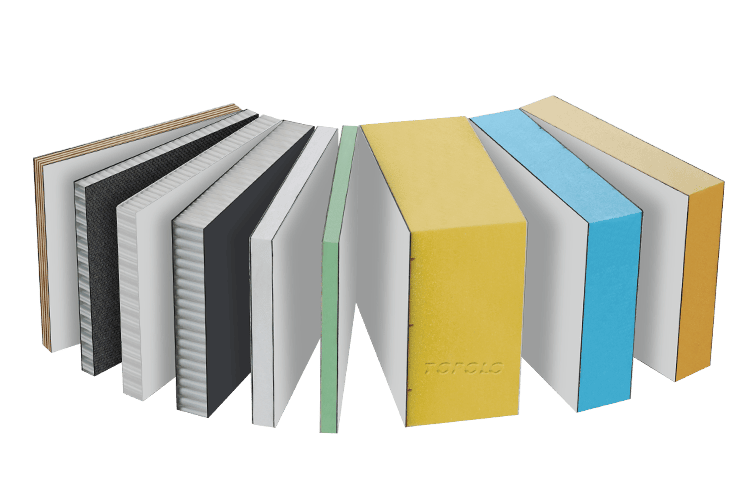

Type of CFRT Sandwich Panels

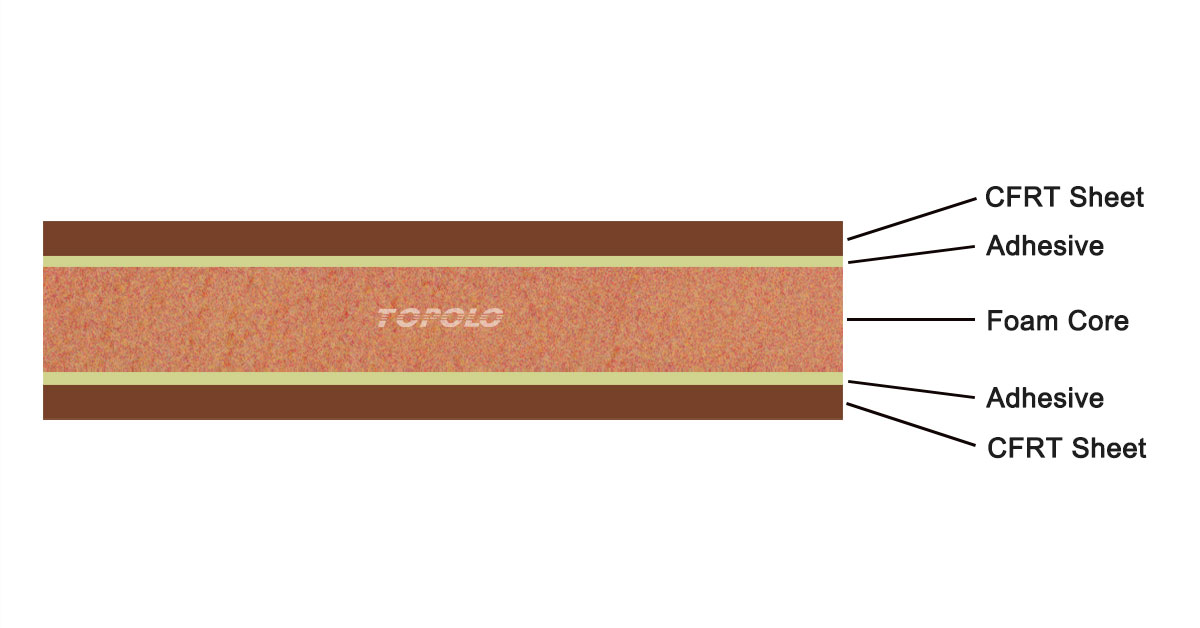

CFRT sheets can be combined with different types of core materials (plywood, polypropylene honeycomb, foam, etc.) through adhesives or thermoplastic composite technology to form high-performance composite panels. These composite panels have excellent mechanical properties and structural stability and are widely used in aerospace, automotive, construction and other fields.

Composite Methods of CFRT Sandwich Panels

Adhesive Bonding

Just like the processing method of thermosetting FRP sandwich panels, CFRT sheets can be bonded with materials of different systems by relying on strong adhesives. The skin and core materials are bonded together with glue, and then pressure is applied to fix the panel for a period of time before it is formed.

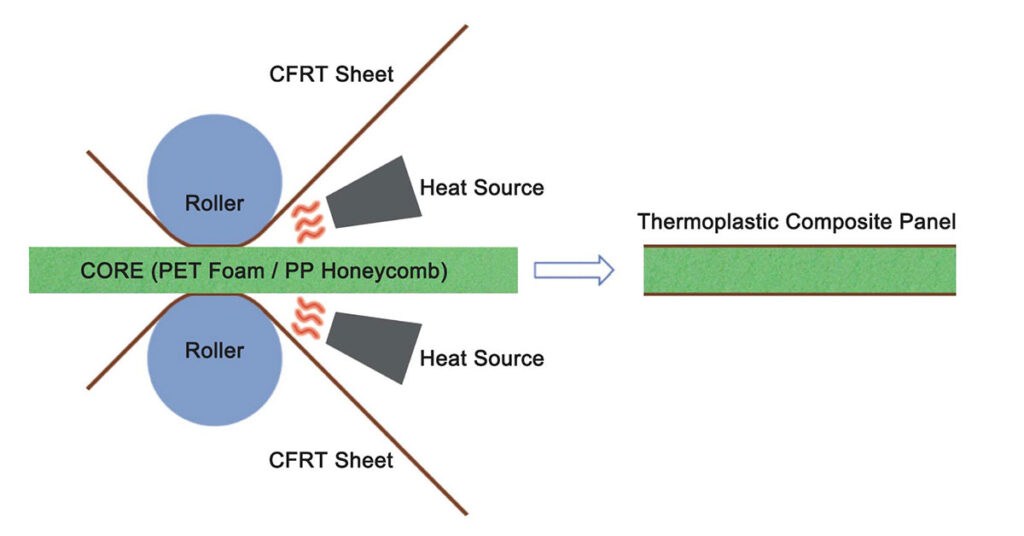

Thermal Composite

Thermal lamination is primarily used for laminating thermoplastic materials, where the CFRT sheets and core material are melted and fused together by heating. Compared to adhesive bonding, this method provides a more efficient production process, resulting in a stronger, more secure bond with higher resistance to cracking.

Learn About Our CFRT Sandwich Panel Products

Applications and Advantages

Box Truck Bodies & Box Trailers

CFRT sandwich panels have a wide range of application prospects for box truck bodies, especially in refrigerated trucks and dry cargo truck bodies. Using CFRT sandwich panels can not only reduce the weight of the vehicle body, but also significantly improve the structural strength and durability.

RV Bodies

As an alternative to thermosetting FRP sandwich panels, CFRT sandwich panels provide a new option for RV manufacturers, especially with unique advantages in improving RV performance, reducing weight, improving durability and environmental protection.

Building Materials

Honeycomb core CFRT sandwich panels are replacing wood and metal in building materials, offering a lighter and more durable alternative. This is particularly true in applications requiring temporary load-bearing, frequent movement, and outdoor exposure. Typical applications include scaffolding, temporary stages, ramps, and stairways.

TOPOLOGROUP – High Standard CFRT Composite Panel Manufacturer

Competitive Advantages and Capabilities

Diverse products

TOPOLOGROUP offers a wide range of CFRT sandwich panels, covering different application areas. Whether it is for lightweight, high-strength structures of transportation such as trucks and RVs, or industrial equipment that requires high heat and corrosion resistance, we can provide customized solutions.

Full specification coverage

TOPOLOGROUP’s CFRT sandwich panels cover multiple sizes and thicknesses from light to heavy, from standard to high specifications, which can meet the personalized needs of different industries for material specifications. Whether it requires thinner panels for light equipment or thicker panels for high-strength, high-load application scenarios, we can provide suitable product specifications.

Leading production technology and innovation

TOPOLOGROUP adopts internationally advanced CFRT manufacturing technology and has independently developed core technologies to ensure that its products are at the industry-leading level in various performance indicators. With continuous technological innovation, TOPOLOGROUP can not only meet existing market needs, but also foresee and solve challenges in future industry development and provide customers with more competitive products.

Environmental protection and sustainable development

TOPOLOGROUP adheres to the concept of environmental protection in the production of CFRT, using recyclable materials and optimizing production processes to reduce energy consumption and waste generation. This not only helps the company reduce its environmental footprint, but also meets increasingly stringent environmental regulations.