CFRT Plywood Panels

Home > Materials > Plywood Sandwich Panels

Continuous fiber reinforced thermoplastic coated plywood

More durable fiberglass-reinforced plywood

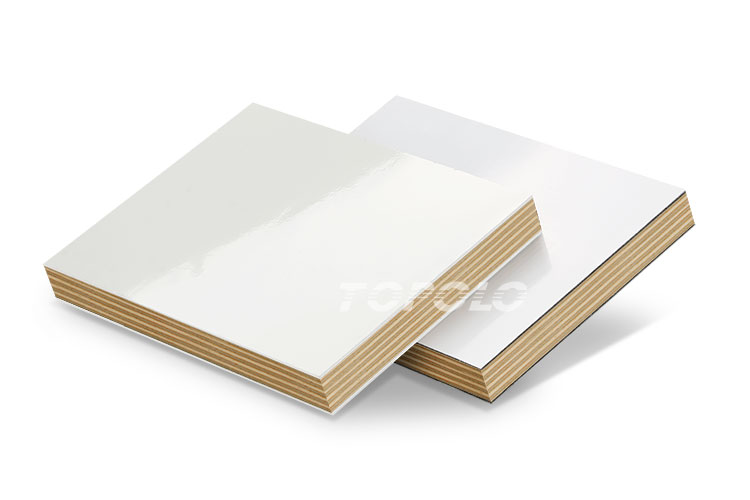

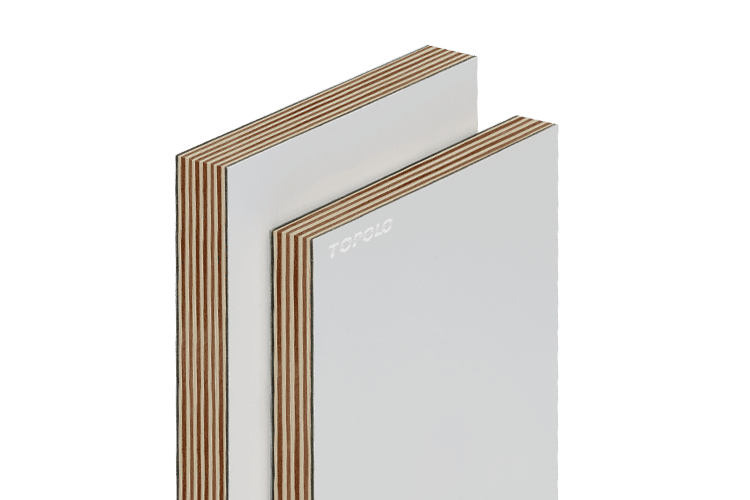

CFRT plywood panels are a new type of fiberglass reinforced covered plywood. They are made by combining multiple layers of CFRT (continuous fiber reinforced thermoplastic) with a plywood core. Compared to thermoset FRP covered plywood, CFRT plywood panels are more durable.

Specification

| Facing | CFRT sheet. (Thickness: 0.7-2.0mm) |

| Surface Treatment | Glossy, matte. |

| Core | Plywood. (Birch, pine, poplar, eucalyptus, oak, etc.) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Thickness | 5-50mm. |

| Length | ≤12000mm. |

| Width | ≤2800mm. |

Structural Diagram

CFRT Replace Thermosetting FRP for Facing

At present, most of the fiberglass reinforced plastics used for plywood sandwich panels on the market are thermosetting resin FRP. Thermosetting FRP has a relatively complex production process, which leads to its high cost and is unaffordable for many users. The new fiberglass reinforced sheet developed by TOPOLOGROUP – CFRT (Continuous Fiber Reinforced Thermoplastic) is a substitute for thermosetting FRP.

- It is far more durable and has greatly reduced costs due to the use of advanced thermoplastic composite process technology.

- CFRT is stronger than thermosetting FRP at the same thickness and can bear more loads. Therefore, to achieve the same mechanical properties, CFRT can be lighter and thinner than thermosetting FRP.

- CFRT is not easy to break, has a wear-resistant surface, and has lower maintenance and servicing costs than thermosetting FRP.

- The number of unidirectional tape layers can be increased according to the demand for structural strength.

- The only drawback is that thermoplastic FRP usually has a smooth and glossy gel coat surface, while the CFRT surface cannot achieve the same effect.

Waterproof Plywood

Marine plywood is a high-quality plywood designed for environments exposed to moisture, humidity, and other harsh conditions. It is made from durable hardwoods, with layers bonded together using a waterproof adhesive that will not delaminate in wet conditions. It is commonly used in marine applications, but its durability and water resistance make it suitable for a variety of other uses as well.

Common Applications

- The thermoplastic prepreg facing plywood sandwich panels is an excellent material for dry freight truck bodies due to its combination of strength, lightness, durability, and moisture resistance. It is particularly useful in environments where the truck needs to endure constant impact and exposure to various weather conditions, providing both performance and longevity for the vehicle.

- Fiberglass plywood is an excellent material for the bodies of budget-friendly RVs such as truck campers, caravans, and teardrop RVs.