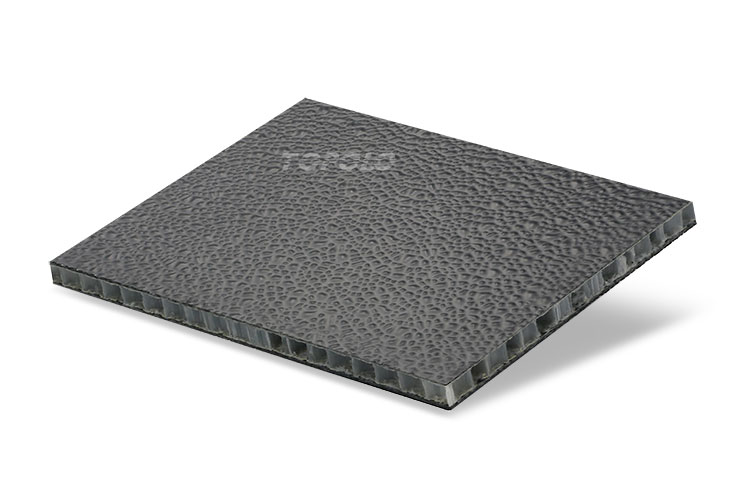

Anti-Slip Polypropylene Honeycomb Panels

Home » Materials » Polypropylene Honeycomb Panels

- Lightweight thermoplastic composite flooring

- Double-sided anti-slip – buy once, use twice

- 100% recyclable

- Efficient production

Feature Description

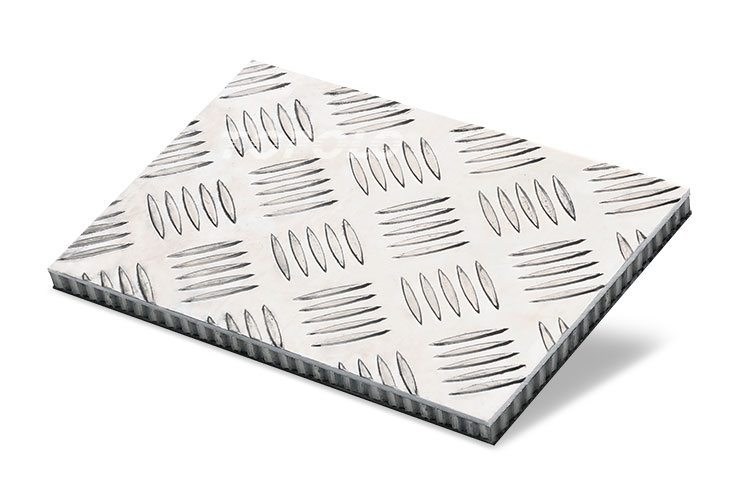

Lightweight

The honeycomb structure makes its density much lower than that of solid wood, plywood, aluminum, and steel anti-slip plates, making it very easy to operate, carry, and install.

Anti-slip

The protective texture is dense and neat, and dust, rain, etc. will not affect the anti-slip effect, effectively preventing operators from falling and goods from sliding.

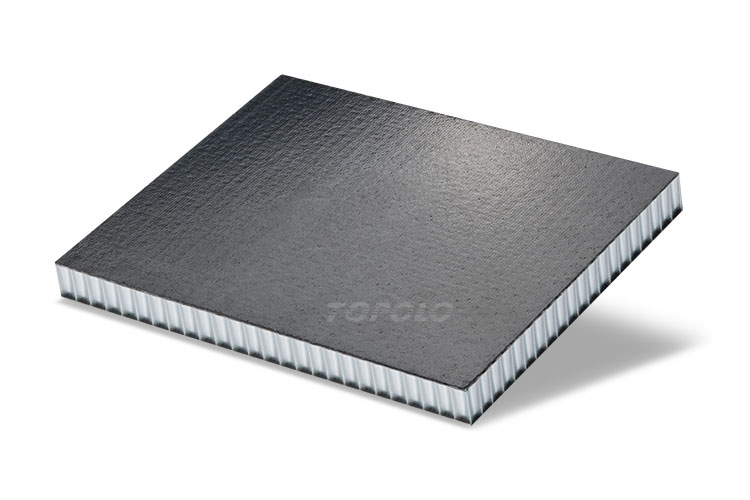

Structural strength

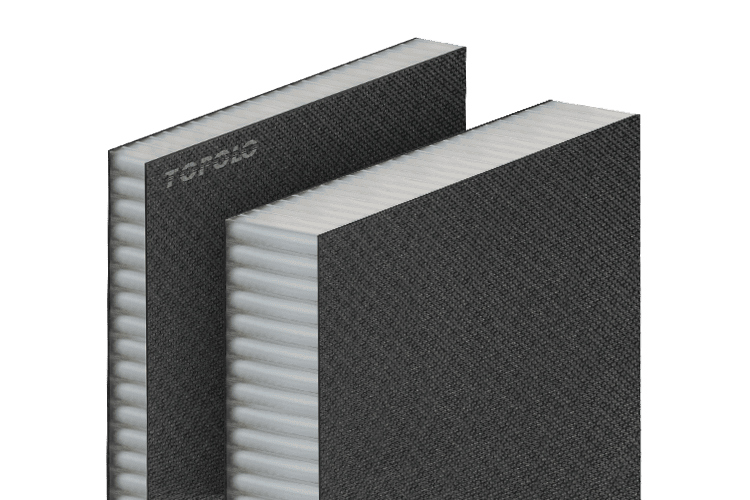

The CFRT (Continuous Glass Fiber Reinforced Thermoplastic) skin offers excellent compression, impact, and abrasion resistance, capable of withstanding impacts from sharp, rough, and extremely heavy objects. The CFRT combined with a high-modulus polypropylene honeycomb core provides unprecedented structural strength.

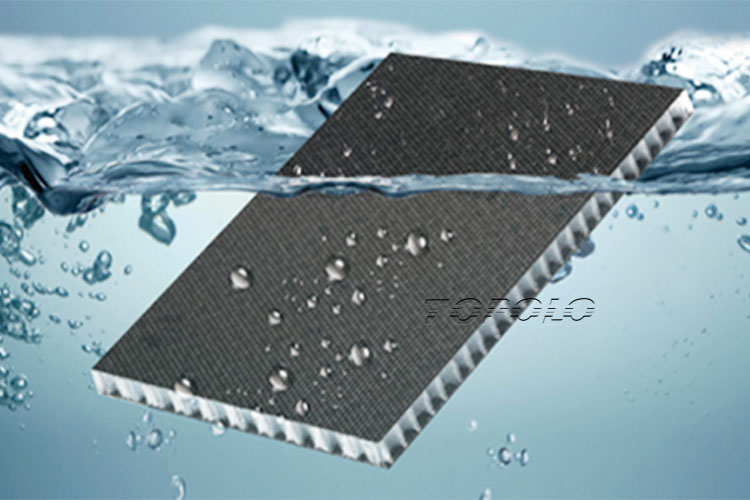

Durable

The thermoplastic material makes it completely waterproof and chemical-resistant. It can also be safely constructed in high temperature and heavy rain weather. Double-sided anti-slip, doubles the service life.

100% recyclable

Made entirely of recyclable thermoplastic polypropylene, it’s a focal point for sustainability.

Easy to process

It can be cut to any size required and fixed to the carrier using rivets, bolts or glue.

Specifications

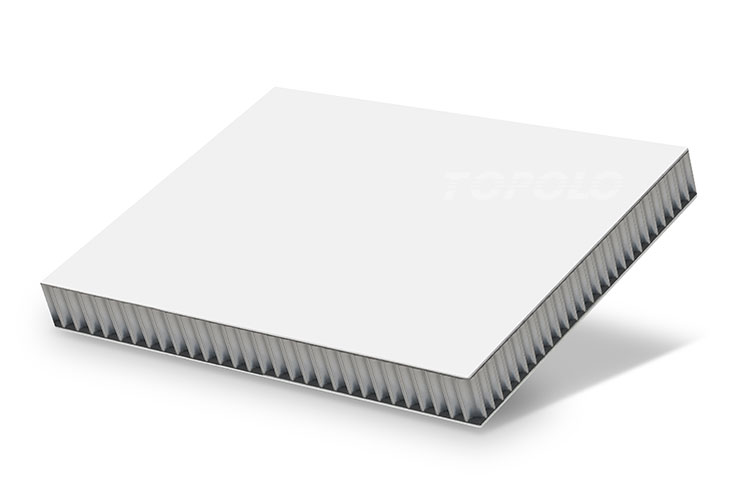

Structural Diagram

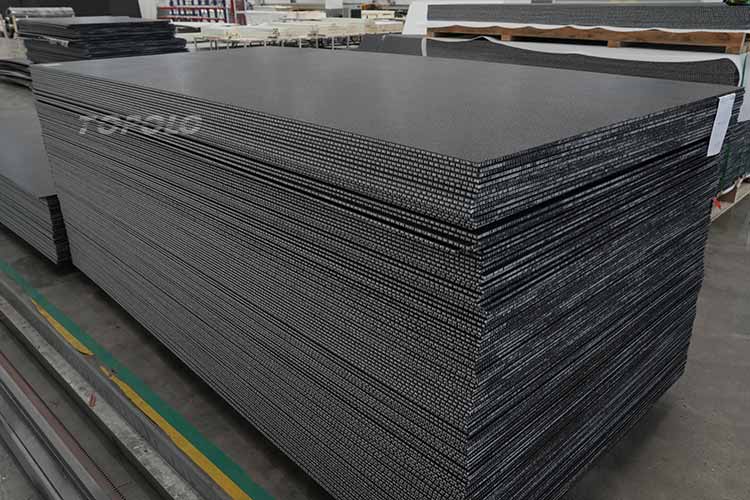

Efficient Production Process

The CFRT sheets are introduced onto the upper and lower surfaces of the honeycomb core, softened by a preheating roller conveyor with anti-skid belts, and then the skin and core are continuously pressed together. After passing through a cooling roller conveyor, they are shaped and an anti-skid texture is pressed onto the surface. This is a very efficient production process with a maximum speed of 6.0m/min.

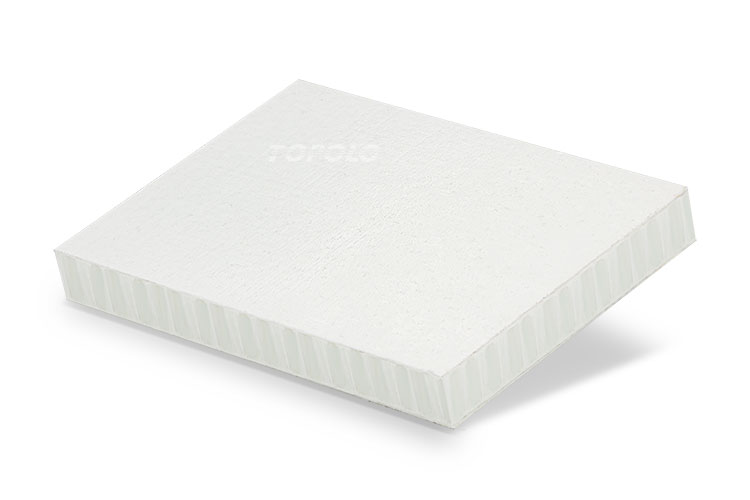

Anti-slip CFRT Sheets

- Multi-layer continuous fiber prepreg tape composite

CFRT sheet is made of multiple layers of continuous glass fiber reinforced thermoplastic prepreg tapes, which are laid at an angle of 0°/90°. The fibers inside the sheet form a dense mesh structure, which greatly enhances the cohesion of the material.

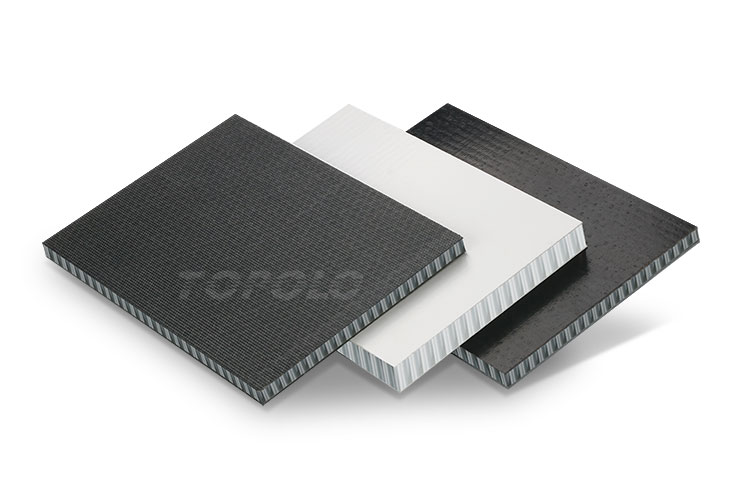

- Fabric-grained anti-slip texture

The anti-slip texture on the CFRT surface is created by pressing it with a non-slip belt. (Due to the joints between the belts, belt marks will appear approximately every 12 meters.)

Common Performance parameters of CFRT sheets

| Resin Type | Thermoplastic Polypropylene |

| Reinforcement Fiber | Continuous Glass Fiber |

| Using Temperature | ≤100°C |

| Fiber Content | 60-75% |

| Density | 1.54-1.63 g/cm³ |

| Thickness (mm) | 0.7-2.0 mm or customized |

| Unidirectional Tape Layers | 2-9 |

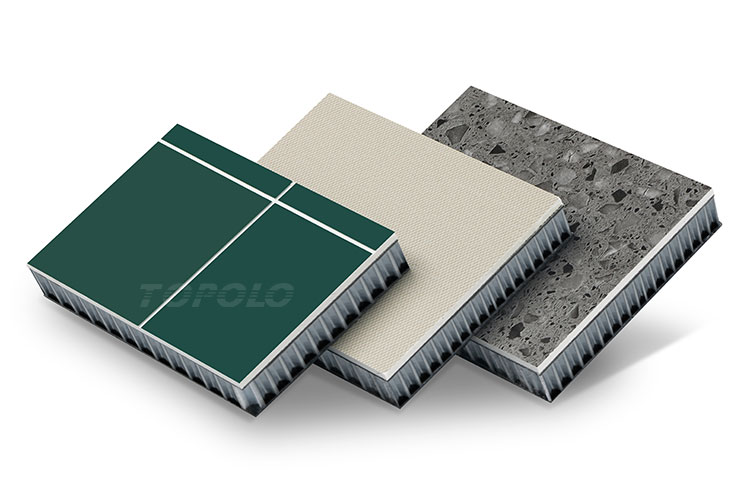

| Laminating Film (Optional) | Polyester Film (Matte/Glossy/Patterned) |

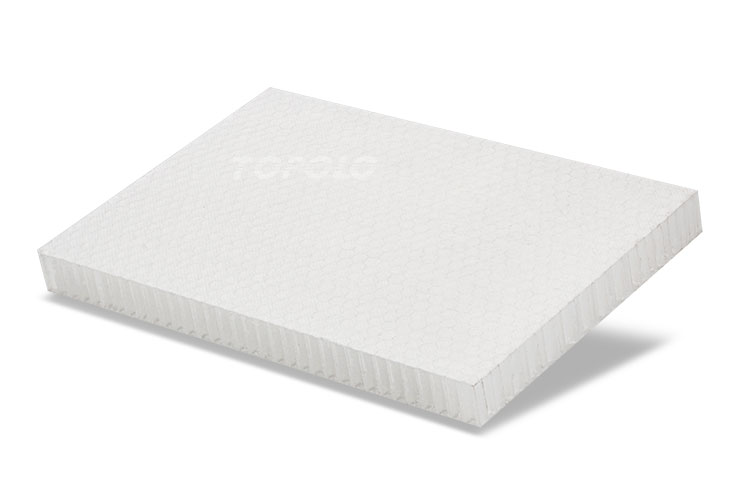

High Modulus Polypropylene Honeycomb

Polypropylene honeycomb is a lightweight, waterproof, strong thermoplastic designed based on the bionic principle of honeycomb. It is a very popular core material for lightweight sandwich panel structures.

Common Performance Parameters of Polypropylene Honeycomb Core

| Cell size(mm) | 8 | 10 | 12 |

| Density(kg/m³) | 80 | 75 | 70 |

| Compressive Strength(MPa) | 1.66 | 1.58 | 1.47 |

| Compressive Modulus(MPa) | 45.7 | 41.2 | 38.9 |

| Shear Modulus(MPa) | 0.50 | 0.45 | 0.40 |

| Operating Temperature(℃) | -40-80 | -40-80 | -40-80 |

| Thermal insulation U value | 2.2 | 2.2 | 2.2 |

Applications

Vehicle floors

- Dry freight truck floors.

- Dropside truck floors.

- Tipper truck floors.

- Trailer ramp doors.

Building floors

- Scaffolding floors.

- Walkways.

- Stair treads.

- Temporary stages.

Core Performance Comparison

| Comparison Dimension | Anti-slip Thermoplastic Honeycomb Panel | Anti-slip Plywood | Anti-slip Aluminum Plate |

| Weight | Light | Heavy | Medium |

| Strength | High | Medium | High |

| Waterproofness | Excellent | Poor | Good |

| Comprehensive Cost | Medium-high | Medium-low | High |

| Durability | Long (10-15 years) | Short (3-8 years) | Medium-long (8-12 years) |

Choose Our Customized Solutions

Tell us about your application requirements and learn more about thermoplastic composite honeycomb panels.