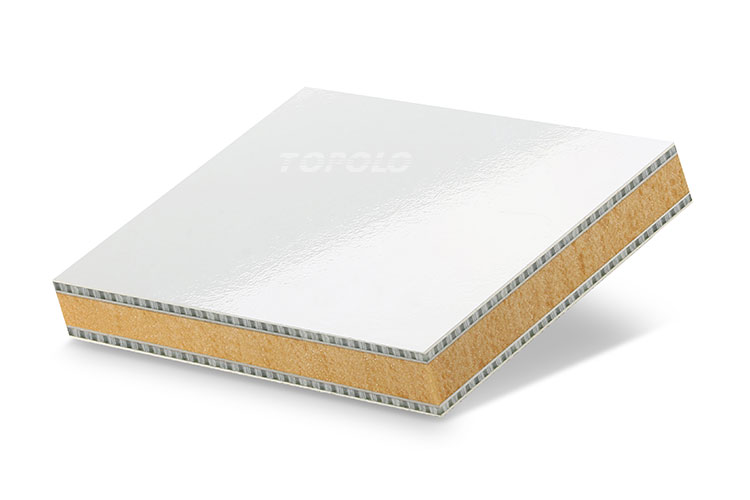

Aluminum Skin PVC Foam Sandwich Panels

Lightweight & strong composite panels

Home » Materials » Foam Sandwich Panels » PVC Foam Sandwich Panels

Aluminum skin PVC foam sandwich panels are a high-performance composite material used in applications requiring lightweight, durable, and thermally insulating properties. These panels consist of two aluminum sheets sandwiched between a PVC foam (polyvinyl chloride foam) core.

Lightweight

The density of aluminum sheet and PVC foam is relatively low, which makes the overall weight of sandwich panels light, easy to carry, install and construct, and also reduces the weight of the finished product.

Thermal insulation

PVC foam has good thermal insulation performance, which can effectively prevent the transfer of heat, reduce the role of thermal insulation, and reduce the energy consumption of air conditioning and heating equipment.

Non-flammable

PVC foam is not easy to burn, and the flame retardant level reaches B1, and the aluminum sheet itself will not burn, which is safer than wood and plastic. The project uses this composite panel to increase the safety index on site.

Waterproof and moisture-proof

Aluminum sheet has a certain waterproof performance, and PVC foam is not easy to absorb water. In a humid environment, the sandwich panel can maintain structural stability for a long time.

Corrosion resistance

Aluminum sheet has good corrosion resistance and can resist the erosion of oxygen, moisture and chemicals in the air. PVC foam also has a certain chemical corrosion resistance, which makes the sandwich panel adaptable to high pH environment.

Aesthetics

Aluminum skin can be painted and surface treated in various colors, with a colorful appearance, showing different styles.

Specifications

| Aluminum Sheet Grade | 1050, 1060, 1100, 3003, 3105, 3004, 5052, 5083, 5754, 6061, 6063, 6082, etc. |

| Surface Treatment | Anodizing, painting, embossing, brushing, sandblasting, polishing, etc. |

| Core | PVC (Polyvinyl Chloride) foam. (Density: 40-250kg/m³) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Thickness | 10-150mm. |

| Length | ≤12000mm. |

| Width | ≤2600mm. |

Schematic Diagram

Aluminum sheet grades and properties

Different grades of aluminum alloy sheets are used as the skin of sandwich panels. Some of them are softer and suitable for buffering and energy absorption, while others are harder and suitable for high-strength structural requirements.

| Series | Typical Alloy | Main Alloying Elements | Tensile Strength (MPa) | Corrosion Resistance | Workability | Heat-treatable |

|---|---|---|---|---|---|---|

| 1000 | 1060 | Pure aluminum | 95-125 | Excellent | Excellent | No |

| 3000 | 3003 | Manganese | 140-180 | Good | Good | No |

| 5000 | 5052 | Magnesium | 230-280 | Good | Good | No |

| 6000 | 6061 | Silicon, Magnesium | 240-290 | Good | Excellent | Yes |

| 7000 | 7075 | Zinc, Magnesium, Copper | 540-580 | Poor | Moderate | Yes |

Aluminum surface treatments

Because aluminum is easy to process, the surface of aluminum plates can be processed into a variety of rich textures and colors while maintaining long-lasting physical and chemical stability, and applied in different scenarios. For example, the smooth polished surface is suitable for wall panels, ceilings, partitions, etc., while the diamond-shaped plates are suitable for floors.

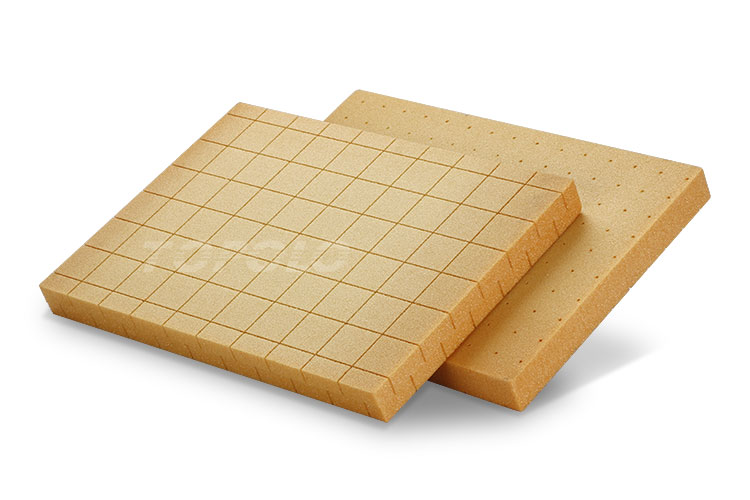

Closed-cell PVC Foam Core

Closed-cell PVC foam is a rigid material with a closed cell structure. Due to its low thermal conductivity and unique honeycomb structure, it performs better than other rigid foams (XPS, PU, PET, EPS) in terms of structural strength, thermal insulation, waterproofing and other properties, and has a balanced overall performance.

PVC Foam Performance Parameters

| Item | P60 | P80 | P100 | P130 | P200 | P250 |

| Density ( kg/m3) | 60 | 80 | 100 | 130 | 200 | 250 |

| Tensile Strength(Mpa) | 1.8 | 2.5 | 3.5 | 4.8 | 7.1 | 9.2 |

| Tensile Modulus(Mpa) | 75 | 95 | 130 | 175 | 250 | 320 |

| Compressive Strength(Mpa) | 0.9 | 1.4 | 2.0 | 3.0 | 4.8 | 6.2 |

| Compressive Modulus(Mpa) | 72 | 90 | 135 | 170 | 240 | 300 |

| Shear Strength(Mpa) | 0.76 | 1.15 | 1.6 | 2.2 | 3.5 | 4.5 |

| Shear Mpdulus(Mpa) | 20 | 27 | 35 | 50 | 85 | 104 |

| Shear Strain(%) | 20 | 30 | 40 | 40 | 40 | 40 |

Common Application of Aluminum Skin PVC Foam Sandwich Panels

Construction field

It is widely used in the exterior walls, roofs, partitions, ceilings and other parts of buildings, such as large buildings such as industrial plants, warehouses, shopping malls, office buildings, gymnasiums, exhibition halls, as well as civil buildings such as houses and villas. It can also be used in temporary buildings, such as mobile board houses, construction site walls, etc.

Refrigeration and insulation field

Due to its good thermal insulation performance, it can be used in the manufacture of refrigeration and insulation equipment such as cold storage, refrigerated trucks, and insulated boxes. It can effectively maintain a low temperature environment, reduce cold loss, and improve the refrigeration effect.

Transportation field

It can be used in the manufacture of body, carriage, cabin and other parts of vehicles such as cars, trains, and ships, which plays a role in reducing weight, heat insulation, sound insulation and noise reduction, and improving the performance and comfort of vehicles.

TOPOLOGROUP also produces aluminium sandwich panels with XPS (Extruded Polystyrene), PET(Polyethylene Terephthalate), and PU (Polyurethane) foam cores. Please contact us for more information.