Aluminum Skin PU Foam Sandwich Panels

Home » Materials » Foam Sandwich Panels » PU Foam Sandwich Panels

Durable composite panels for vehicles and buildings

Flat aluminum skin PU (polyurethane) foam sandwich panels are a new type of laminated composite panel. Unlike aluminum sandwich panels produced by the injection molding method, they are made by processing pre-expanded PU foam into the desired dimensions, then bonding it to aluminum sheet with an adhesive, and then laminating it under high pressure in a vacuum environment. This process results in a smooth surface and tight adhesion, surpassing injection molding products in structural strength, practicality, and aesthetics.

Specifications

| Aluminum Sheet Grade | 1050, 1060, 1100, 3003, 3105, 3004, 5052, 5083, 5754, 6061, 6063, 6082, etc. |

| Surface Treatment | Anodizing, painting, embossing, brushing, sandblasting, polishing, etc. |

| Surface Color | RAL color series. |

| Core Material | PU (Polyurethane) foam. (Density: 28-50kg/m³). |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Panel Thickness | 10-150mm. |

| Panel Length | ≤12000mm. |

| Panel Width | ≤2600mm. |

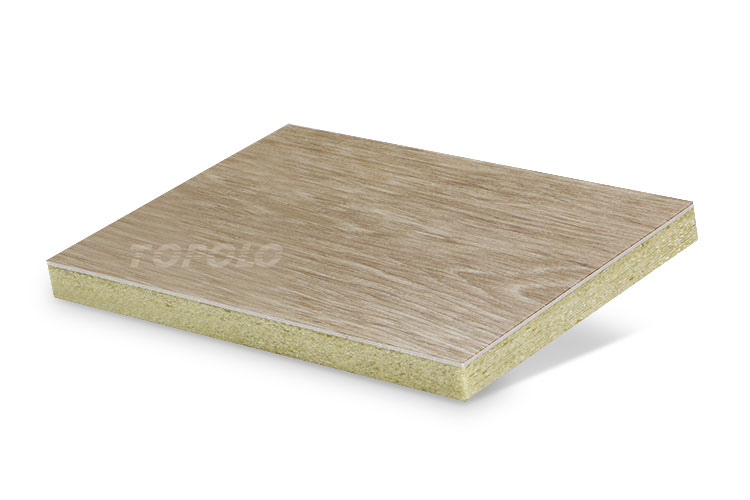

Structural Diagram

Aluminum sheet grades and properties

Different grades of aluminum alloy sheets are used as the skin of sandwich panels. Some of them are softer and suitable for buffering and energy absorption, while others are harder and suitable for high-strength structural requirements.

| Series | Typical Alloy | Main Alloying Elements | Tensile Strength (MPa) | Corrosion Resistance | Workability | Heat-treatable |

|---|---|---|---|---|---|---|

| 1000 | 1060 | Pure aluminum | 95-125 | Excellent | Excellent | No |

| 3000 | 3003 | Manganese | 140-180 | Good | Good | No |

| 5000 | 5052 | Magnesium | 230-280 | Good | Good | No |

| 6000 | 6061 | Silicon, Magnesium | 240-290 | Good | Excellent | Yes |

| 7000 | 7075 | Zinc, Magnesium, Copper | 540-580 | Poor | Moderate | Yes |

Aluminum surface treatments

Because aluminum is easy to process, the surface of aluminum plates can be processed into a variety of rich textures and colors while maintaining long-lasting physical and chemical stability, and applied in different scenarios. For example, the smooth polished surface is suitable for wall panels, ceilings, partitions, etc., while the diamond-shaped plates are suitable for floors.

PU Foam Core

- Density: 28-50kg/m³.

- Thermal conductivity: ≤0.024W/(m.k).

- Bonding strength: ≥100kPa.

- Rate of dimensional change(70ºCx48h): 1mm.

- Compressive strength: ≥160kPa.

- Tensile strength: ≥205kPa.

- Elongation at break: ≥10%.

- Porosity by closed pore: ≥92%.

- Water absorption: ≤3%.

- Water vapor permeability; ≤5Hg/(Pa.m.s).

- Anti-permeability(1000mmx24h)(1000mm water column X24h hydrostatic pressure): ≤5mm.

Applications

Aluminum skin PU foam sandwich panels are mostly used in various refrigeration equipment and buildings, especially those that require a strong enough supporting structure.

Such as:

- Refrigerated truck bodies for special purposes.

- Cold rooms and cold storages.

- Insulation shells for outdoor equipment.

- Wall panels and roof panels for factories, warehouses, etc.

- Agricultural and animal husbandry buildings.

TOPOLOGROUP also produces aluminium sandwich panels with XPS (Extruded Polystyrene), PET(Polyethylene Terephthalate) and PVC (Polyvinyl Chloride) foam cores. Please contact us for more information.