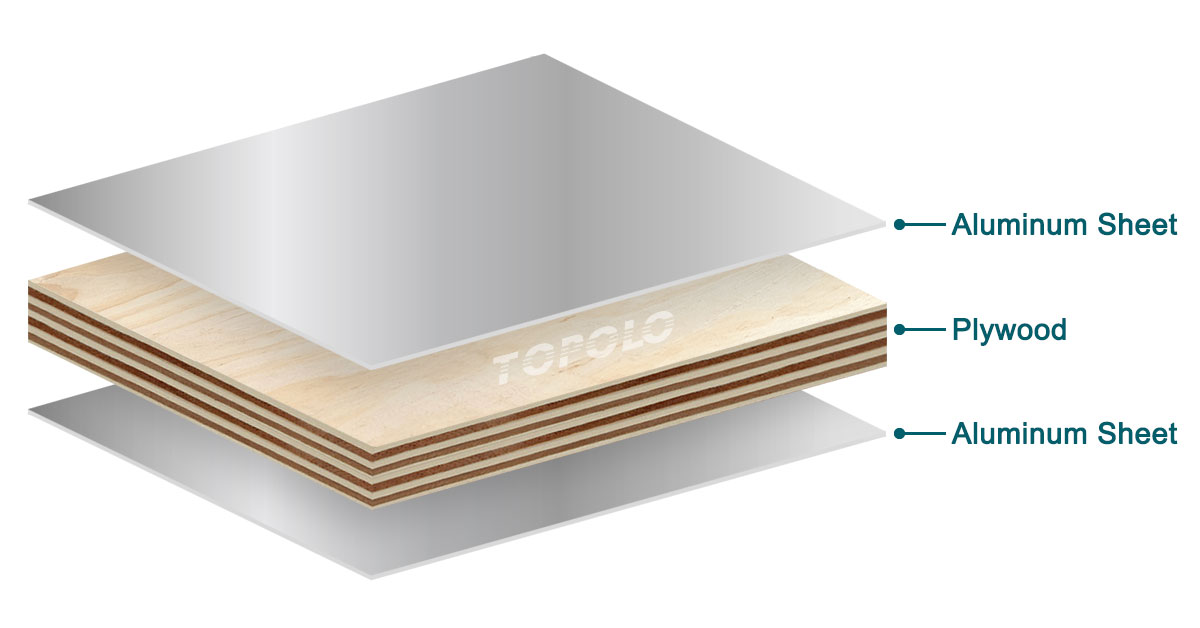

Aluminum plywood panels are composed of wood plywood sheets, coated on one or both sides with aluminum sheets, and bonded together with adhesives. Combining the advantages of wood and metal, they are often used in applications requiring lightweight, decorative, and strong properties.

Advantages of aluminum faced plywood

☑ Fireproof: Ordinary plywood panels have a fire rating of only B2, while aluminum-faced plywood achieves A.

☑ Moldproof: They effectively block moisture, eliminating the problem of wood becoming moldy and darkening.

☑ Termite-resistant: The aluminum sheet is durable and bite-resistant, providing a complete barrier against termites and other pests.

☑ Deformation-resistant: Their structural stability maintains the flatness of large panel surfaces.

☑ Easy to process: They can be sawed, drilled, and milled, making them easy to install.

Specification of Aluminum Plywood Panels

| Aluminum Sheet Grade | 1050, 1060, 1100, 3003, 3105, 3004, 5052, 5083, 5754, 6061, 6063, 6082, etc. |

| Surface Treatment | Anodizing, painting, embossing, brushing, sandblasting, polishing, etc. |

| Surface Color | RAL series. |

| Core | Plywood. (Birch, pine, poplar, eucalyptus, oak, etc.) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Total Thickness | 10-50mm. |

| Length | ≤12000mm. |

| Width | ≤2600mm. |

Common application of aluminum plywood panels

☑ Vehicle Manufacturing: Wall panels for trucks, trailers, and other vehicles.

☑ Architectural Decoration: Wall panels, ceiling panels, floor panels and door panels.

☑ Furniture Manufacturing: Cabinets, countertops, and decorative panels.

☑ Industrial Equipment: Equipment casings, protective panels, and packaging boxes.

Panel structural diagram

Waterproof plywood core

The core of the sandwich panel is made of plywood, a strong and flexible wood product composed of multiple layers of veneer. Plywood provides the necessary structural integrity and rigidity to the panel. Our plywood is treated to be fire and water resistant and suitable for marine environments.

Plywood performance parameters

| Parameter | Details |

|---|---|

| Material | Beech, camphor, willow, poplar, birch, eucalyptus, etc. |

| Glue Type | Phenolic resin adhesive. |

| Thickness | 4mm to 25mm. |

| Size | 1220mmx2440mm, 1250mmx2500mm, 1530x3150mm. |

| Density | 500-700 kg/m³. |

| Moisture Content | 6-14%. |

| Water Absorption Rate | <8%. |

| Flame Retardant Level | B1. |

| Boiling Water Test | No delamination after 72 hours in boiling water. |

| Modulus of Rupture (MOR) | 30-50 MPa depending on the type and thickness. |

| Modulus of Elasticity (MOE) | 6000-9000 MPa. |

Aluminum sheet grades and properties

Different grades of aluminum alloy sheets are used as the skin of sandwich panels. Some of them are softer and suitable for buffering and energy absorption, while others are harder and suitable for high-strength structural requirements.

| Series | Typical Alloy | Main Alloying Elements | Tensile Strength (MPa) | Corrosion Resistance | Workability | Heat-treatable |

|---|---|---|---|---|---|---|

| 1000 | 1060 | Pure aluminum | 95-125 | Excellent | Excellent | No |

| 3000 | 3003 | Manganese | 140-180 | Good | Good | No |

| 5000 | 5052 | Magnesium | 230-280 | Good | Good | No |

| 6000 | 6061 | Silicon, Magnesium | 240-290 | Good | Excellent | Yes |

| 7000 | 7075 | Zinc, Magnesium, Copper | 540-580 | Poor | Moderate | Yes |

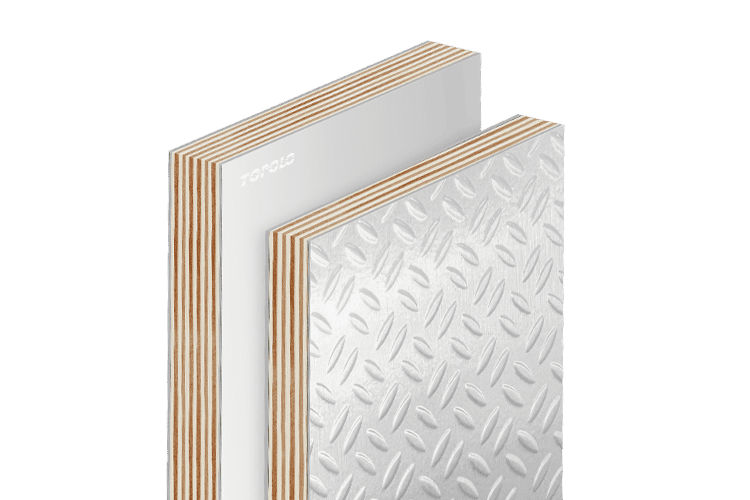

Aluminum surface treatments

Because aluminum is easy to process, the surface of aluminum plates can be processed into a variety of rich textures and colors while maintaining long-lasting physical and chemical stability, and applied in different scenarios. For example, the smooth polished surface is suitable for wall panels, ceilings, partitions, etc., while the diamond-shaped plates are suitable for floors.