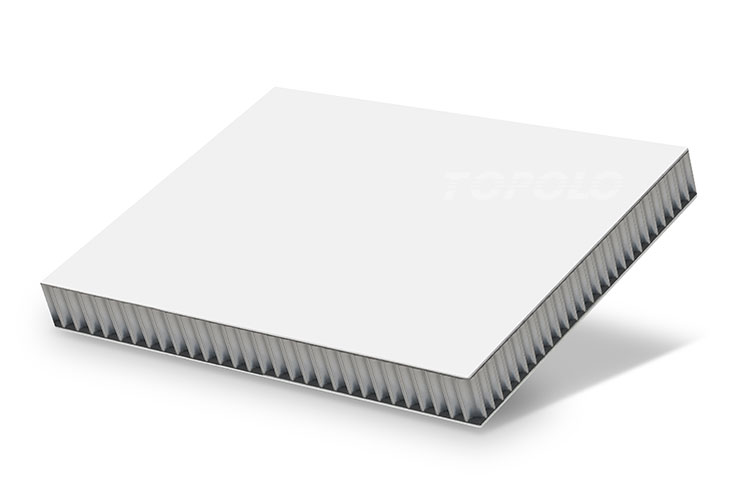

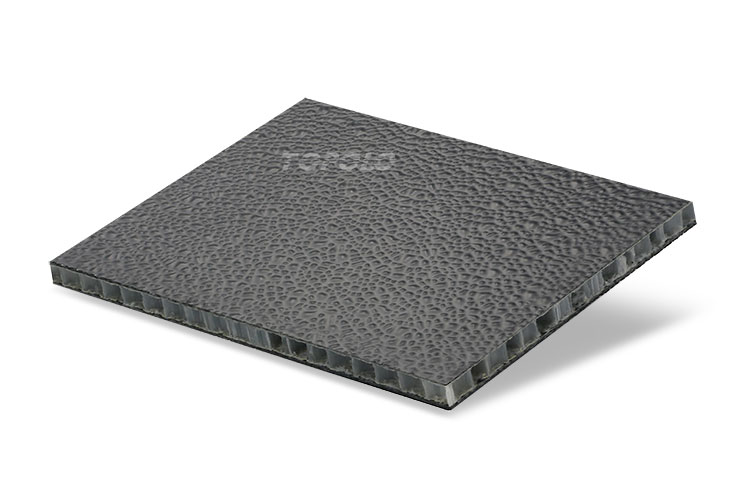

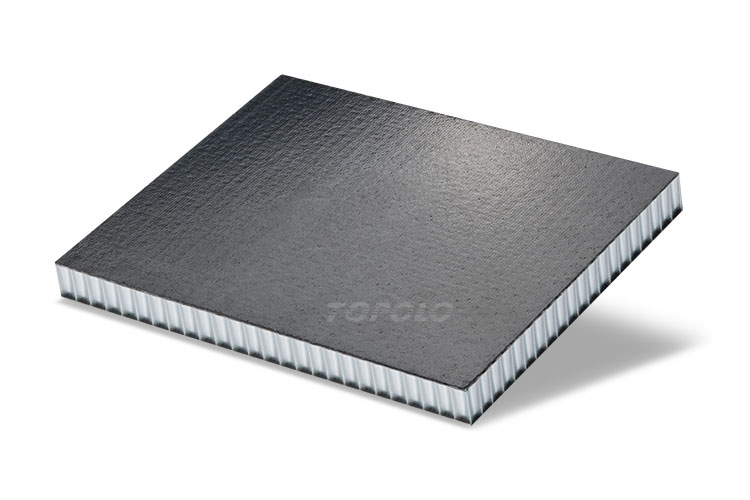

ACP Skin Polypropylene Honeycomb Panels

Polypropylene Honeycomb + Aluminum Composite Panels

Polypropylene honeycomb panels faced with ACP panels (Aluminum Composite Panels) provide higher structural strength compared to aluminum sheet facing. It solves the challenge of insufficient strength of aluminum facing honeycomb panels through the complementary material properties and structural synergy innovation.

- High specific strength and stiffness.

- Shear and impact resistance.

- High energy absorption capacity.

- Fire and weather resistance.

Specification

| Facing | Aluminum Composite panels. (Thickness: 2.0-6.0mm) |

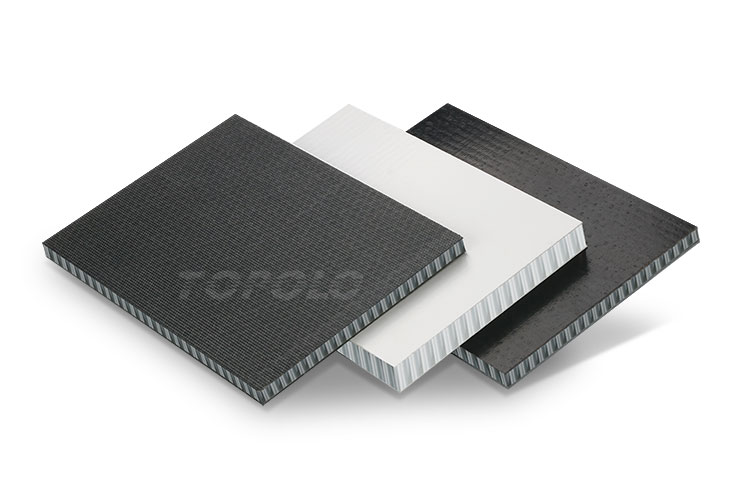

| Surface Treatment | Glossy, matte. |

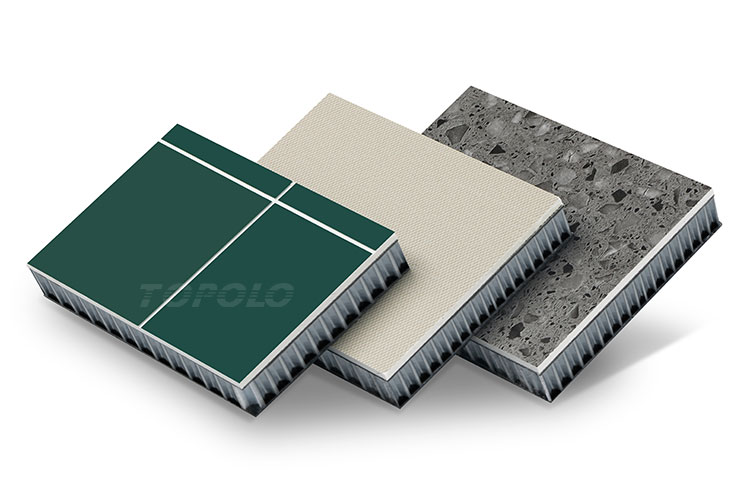

| Surface Color | RAL series. (White, black, yellow, blue, brown, gray, etc.) |

| Core | PP (Polypropylene ) Honeycomb. (Density: 80-120kg/m³) |

| Composite Method | Unsaturated polyester adhesive, polyurethane adhesive, etc. |

| Thickness | 10-150mm. |

| Length | ≤8000mm. |

| Width | ≤1500mm. |

| Working Temperature | -40℃ to +80℃ |

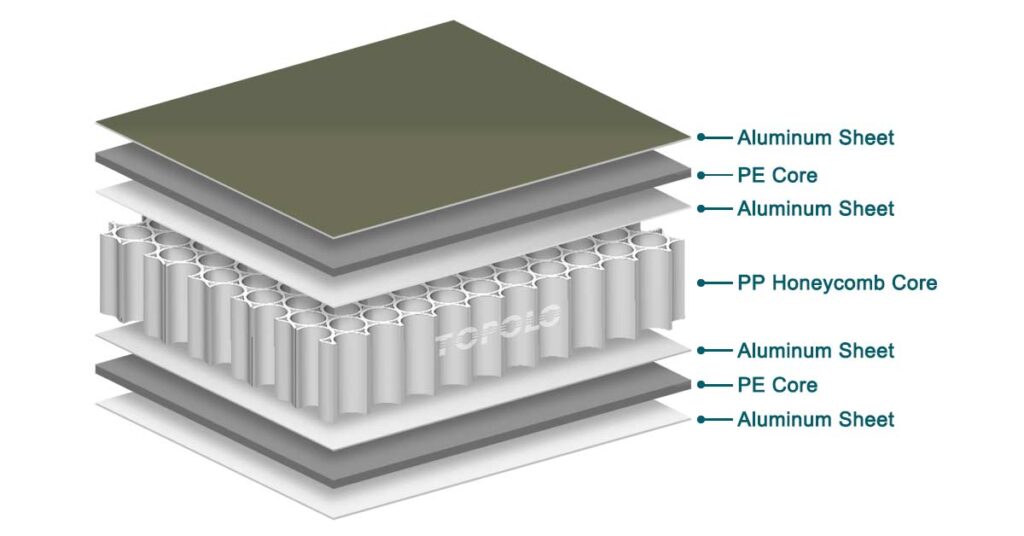

Structural Diagram

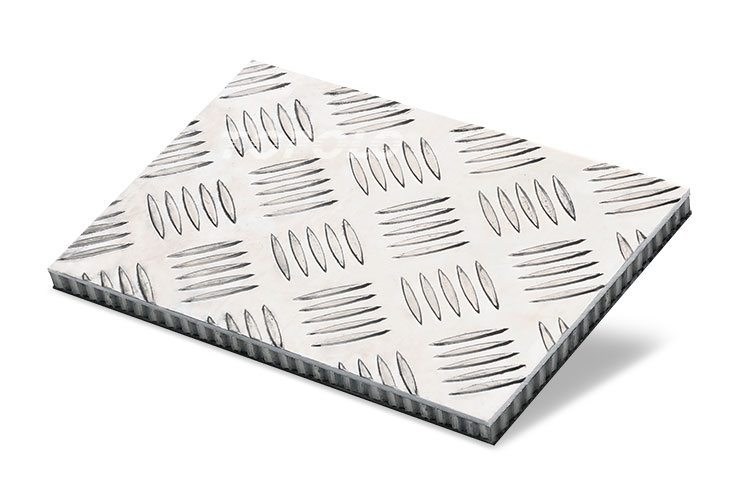

Aluminum Composite Panels

Aluminum composite panels are constructed by laminating aluminum layers with a PE (Polyethylene) core material using a polymer adhesive. They perfectly blend the texture of metal with the lightweight properties of plastic. This composite structure, comprised of vastly different materials, retains the core strengths of the original materials while cleverly addressing their respective performance shortcomings, resulting in a series of exceptionally comprehensive properties.

- Decorative: It offers a luxurious feel and rich, vibrant decorative effects.

- Durability: It is resistant to weather, corrosion, and impact.

- Safety: It offers outstanding fire and moisture resistance, as well as effective sound insulation, heat insulation, and earthquake resistance.

Specification of ACP Panels

| Panel Thickness | 2mm, 3mm, 4mm, 5mm, 6mm. |

| Aluminum Grade | 1100, 3003, 5005, etc. |

| Aluminum Thickness | 0.08mm-0.50mm. |

| Surface Treatment | Wood grain, brushed, mirror, anodized, powder coating, etc. |

| Surface Color | RAL Series. |

| Surface Coating | PE/PVDF. |

| Core | PE (Polyethylene) plastic. |

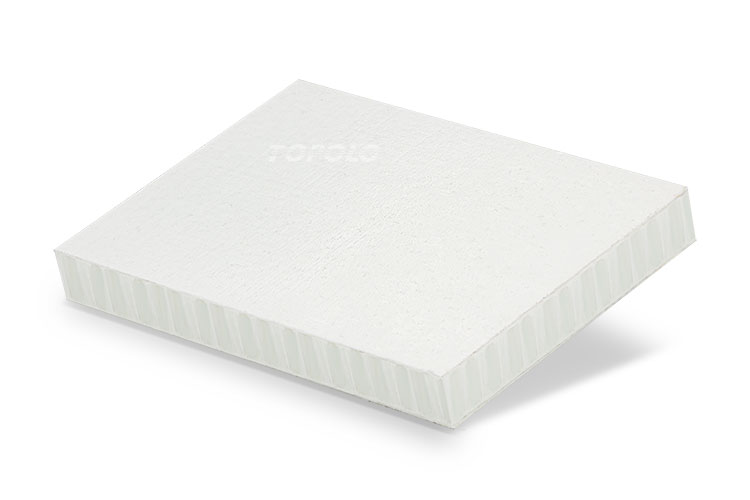

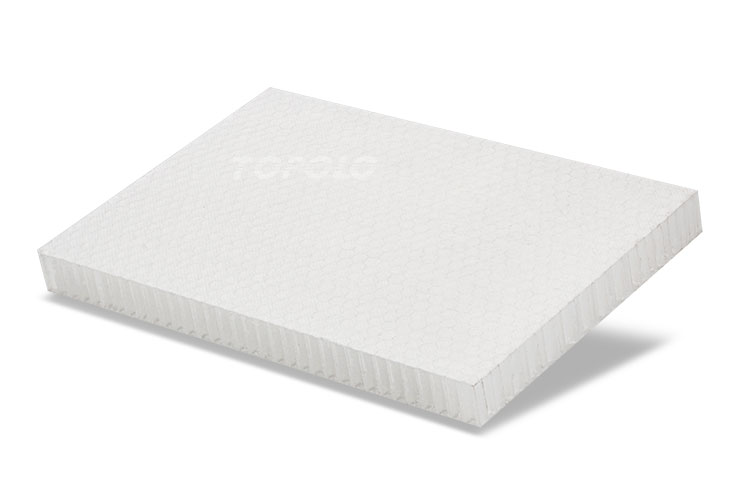

Lightweight Polypropylene Honeycomb Core

Polypropylene honeycomb is a lightweight, rigid thermoplastic used as the core of sandwich panel structures. Like aluminum honeycomb, it is also recyclable. Different honeycomb cell sizes have different densities and provide different mechanical strengths. Our honeycomb core is made of high modulus thermoplastic polypropylene plastic, which is flexible and not easily deformed.

Common Performance Parameters of Polypropylene Honeycomb Core

| Cell size(mm) | 8 | 10 | 12 |

| Density(kg/m³) | 80 | 75 | 70 |

| Compressive Strength(MPa) | 1.66 | 1.58 | 1.47 |

| Compressive Modulus(MPa) | 45.7 | 41.2 | 38.9 |

| Shear Modulus(MPa) | 0.50 | 0.45 | 0.40 |

| Operating Temperature(℃) | -40-80 | -40-80 | -40-80 |

| Thermal insulation U value | 2.2 | 2.2 | 2.2 |

Honeycomb Panel Series

Applications

ACP skin polypropylene honeycomb panels are commonly used in buildings and vehicles.

Buildings and vehicles

- building Curtain walls.

- Interior ceilings and partitions.

- Modular buildings and temporary facilities.

Vehicles

- Box truck bodies.

- Recreational vehicle bodies.

- Trailers.