Home » Sandwich Panels » Honeycomb Panel Series

Specifications

- Thickness: 10-50mm.

- Width: ≤2.8m.

- Length: ≤12m.

- Facing: CFRT sheet. (Customized: 0.7-2.0mm)

- Surface Color: White, black .

- Surface Treatment: Flat, Anti-slip.

- Core: Polypropylene (PP) honeycomb. (Density: 80-120kg/m³)

DESCRIPTION

As a fully recyclable composite material, PP (polypropylene) honeycomb panels offer a modern and sustainable solution for constructing dry freight truck bodies. They combine lightweight performance, mechanical strength, and durability, providing multiple advantages for both manufacturers and operators.

☑ Lightweight Efficiency

The honeycomb core structure minimizes weight without sacrificing strength, reducing the total vehicle mass. This improves fuel economy, increases payload capacity, and lowers operating costs.

☑ Exceptional Durability

PP honeycomb panels are resistant to water, corrosion, and most chemicals. They do not absorb moisture, swell, or rot, ensuring long-term performance even in demanding road and weather conditions.

☑ High Compression Strength

The rigid honeycomb design provides outstanding compressive and impact resistance. This enhances structural stability, keeping the truck body firm and safe under heavy loads.

TOPOLOGROUP – PP Honeycomb Composite Panel Manufacturer in China

TOPOLOGROUP manufactures fiberglass reinforced polypropylene honeycomb panels designed for constructing various types of dry freight truck bodies. These panels combine strength, lightweight structure, and durability, making them ideal for side walls, roofs, partitions, and floors.

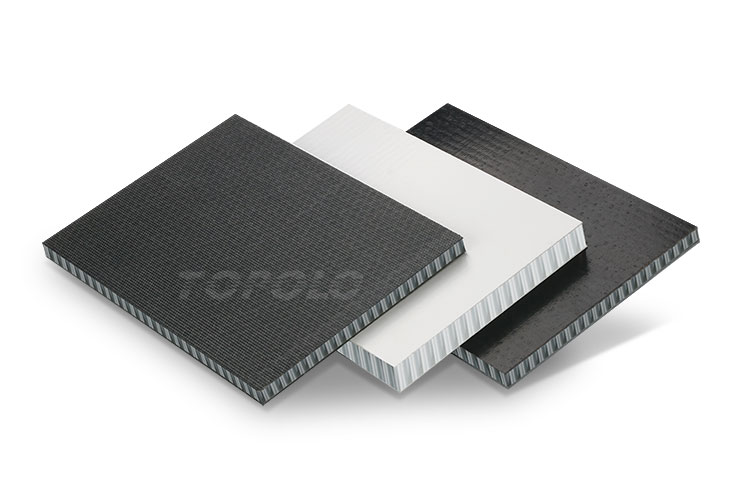

Common Types of PP Honeycomb Panels

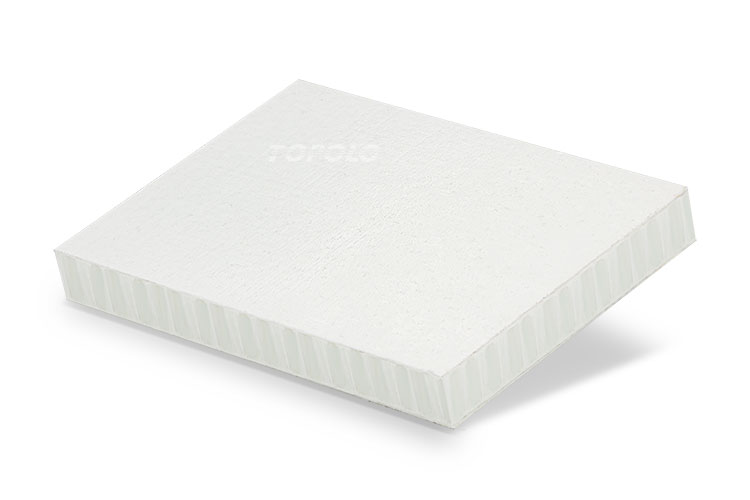

White Flat Honeycomb Panels

- Features: Surface laminated with a decorative film for enhanced appearance and protection.

- Surface Finish: Available in glossy or matte options.

- Applications: Side walls, door panels, roof panels, and partitions.

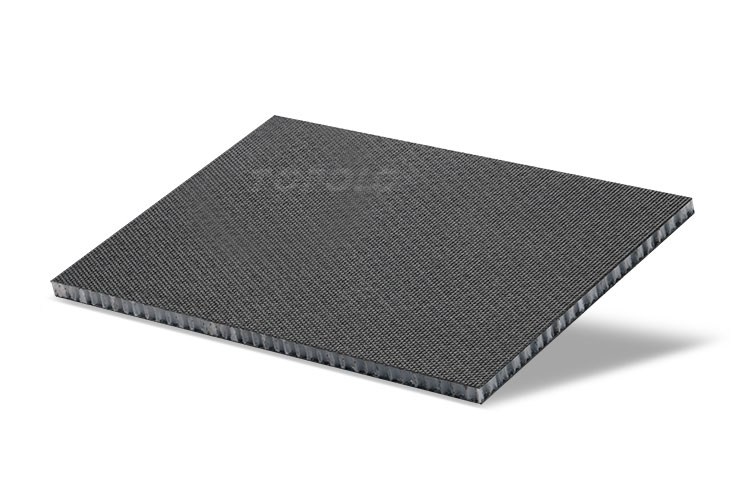

Anti-Slip Honeycomb Panels

- Features: Textured surface with anti-slip patterns for improved traction and safety.

- Applications: Floor panels.

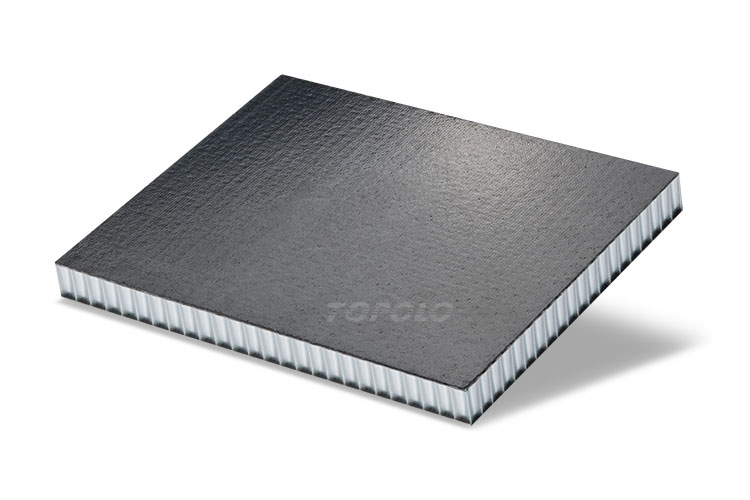

Black Flat Honeycomb Panels

- Features: Made from PP sheets with added carbon black; no protective film.

- Applications: Subfloor panels (can be covered with other materials).

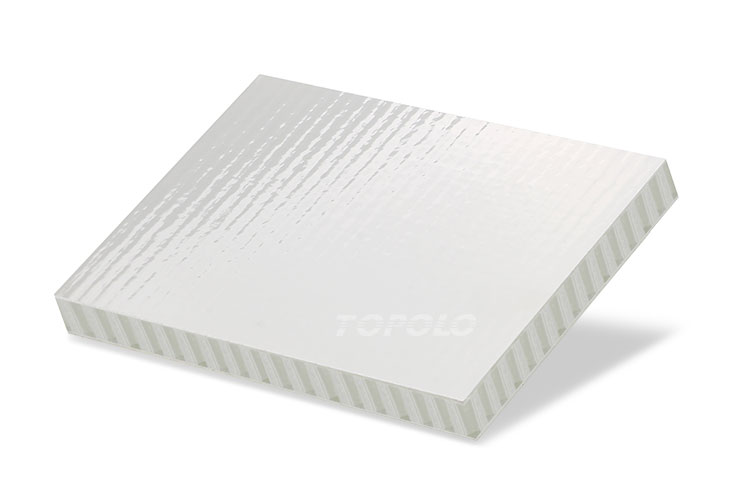

Natural Color Honeycomb Panels

- Features: No color additives, no protective film, partially translucent—allowing natural light to pass through.

- Applications: Roof panels (reduces need for daytime lighting) and subfloors (can be covered with other materials).