Home » Sandwich Panels » PP Foam Panel Series

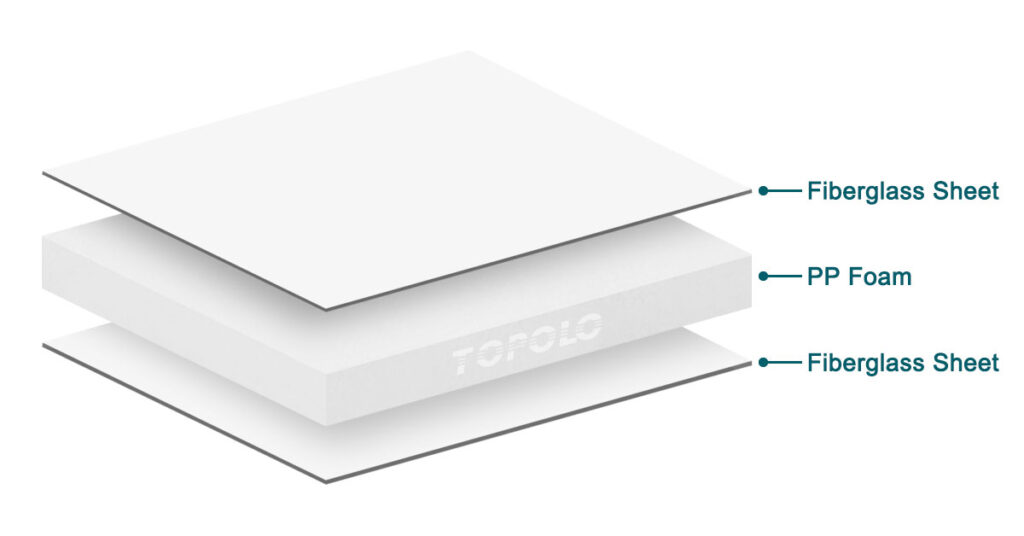

The composite panel is formed from a closed-cell MPP foam core and CFRT (continuous fiber reinforced thermoplastic) PP sheets through a glue-free thermal lamination process.

Specifications

- Thickness: 10-50mm

- Length: ≤12m.

- Width: ≤2.8m.

- Skin: CFRT (Continuous Fiber Reinforced Thermoplastic) sheet. (0.7-2.0mm)

- Core: MPP (Microcellular Polypropylene) foam. (Density: 60kg/m³).

Description

Many vehicle manufacturers are actively seeking lightweight, high-performance, and easily recyclable composite panels for vehicle body construction to achieve goals of weight reduction and sustainability. The fiberglass reinforced polypropylene (PP) foam sandwich panel is exactly the type of material that meets these needs.

Product Features

- Lightweight: MPP foam offers low density and excellent rigidity, reducing the overall weight of the composite panel.

- Durable: Continuous glass fiber-reinforced PP (polypropylene) sheets offer excellent rigidity and abrasion resistance.

- Environmentally friendly and recyclable: PP thermoplastic material is 100% recyclable, aligning with green manufacturing trends.

- Glue-free and environmentally friendly process: Utilizing hot-melt lamination technology, the layers bond tightly together, resulting in superior durability compared to traditional adhesive bonding.

What is MPP Foam?

MPP Foam (Modified Polypropylene Foam) is a closed-cell thermoplastic foam material made from polypropylene (PP) through advanced physical or chemical foaming processes. Based on the inherent advantages of polypropylene, MPP foam is modified to improve cell uniformity, toughness, and thermal stability, resulting in a high-performance structural foam that combines lightweight, strength, and heat resistance.

- Closed-cell structure

- Thermoplastic and recyclable

- Fine and uniform cells

Continuous Fiberglass Reinforced PP Sheet

It is a high-strength thermoplastic composite sheet made of polypropylene (PP) as the matrix resin and continuous glass fibers as the reinforcement, produced through a continuous hot-pressing process. Unlike traditional short-fiber or fabric-reinforced materials, the continuous fibers are oriented and distributed in a specific direction within the sheet, providing greater strength, stiffness, and fatigue resistance.

Structural Diagram

Typical Applications

Suitable for various vehicle structural parts, including:

- Side Wall Panels

- Floor Panels

- Roof Panels

- Partition Panels

Widely used in:

- Dry Freight Trucks.

- Small Refrigerated Trucks.

- Enclosed Trailers.

- RVs.

Get Your Custom Composite Panels

As one of the most dynamic fiberglass foam sandwich panel manufacturers in China, TOPOLOGROUP specializes in providing lightweight composite panel solutions. We produce a wide variety of foam-core composite panels to meet diverse application scenarios and functional requirements. With advanced production equipment, strict quality control and flexible customization capabilities, TOPOLOGROUP provides customers with reliable, durable and environmentally friendly composite panel solutions, making it your ideal composite panel partner.