Home » Truck & Trailer Solutions » Truck & Trailer Kits

The core competitiveness of refrigerated trucks lies in maintaining a stable low-temperature environment within the vehicle body, a capability that is highly dependent on the overall insulation performance of the vehicle body. Among the various vehicle body components, the doors are recognized as key weak points. Their insulation and sealing defects directly restrict the overall transportation performance of the vehicle and become a key factor affecting cold chain safety.

Impact of Refrigerated Truck Door Performance on Cold Chain Transportation

Poor door sealing and insulation can disrupt the low-temperature environment within refrigerated trucks through multiple channels, ultimately threatening cargo quality and transportation safety.

Poor sealing can lead to a series of problems: Failed door seals allow hot air and moisture to penetrate directly into the vehicle interior. When this moisture cools, it easily forms frost or ice on the inside of the door, door frame, and surrounding areas, directly impacting goods near the door. For example, fresh produce may suffer from frostbite and mold due to localized low-temperature fluctuations, while frozen goods may thaw repeatedly.

Inadequate insulation increases the refrigeration burden: Door panels without high-efficiency insulation materials have significantly higher thermal conductivity, causing rapid loss of cold air from the vehicle interior through the door panels. To maintain the set low temperature, the refrigeration unit must operate continuously at high load, increasing fuel and electricity consumption and shortening the life of the refrigeration equipment.

TOPOLOGROUP uniquely designed refrigerated truck doors provide better thermal insulation and sealing performance.

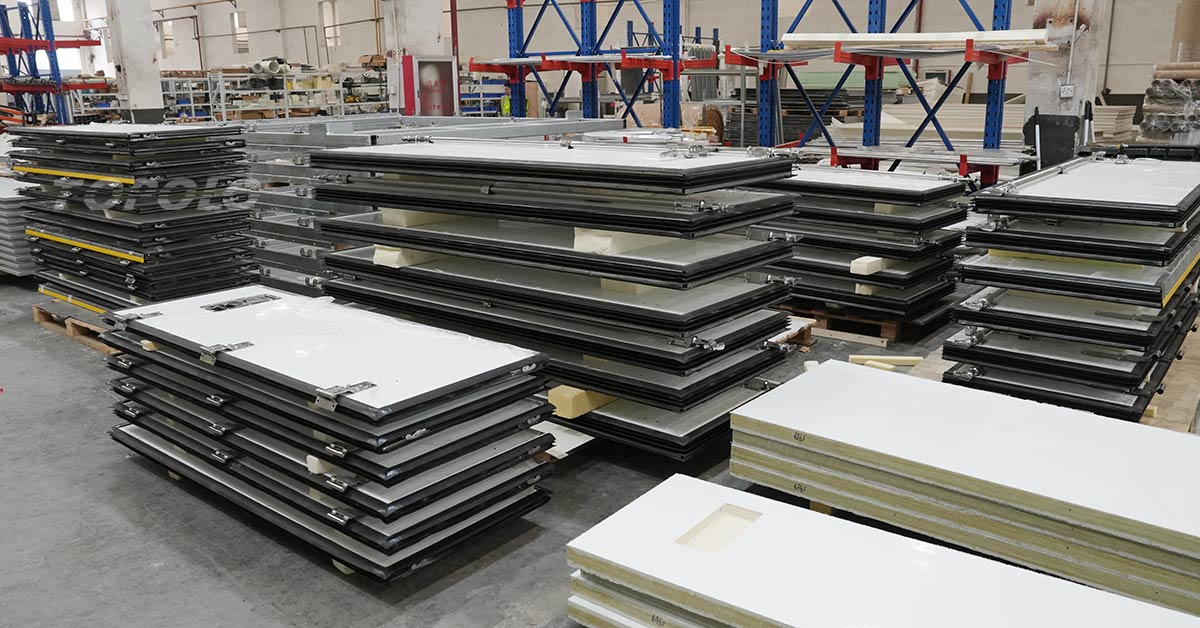

Specification of Refrigerated Truck Doors

| Size | Customizable |

| Thickness | 80/100/120/150mm. |

| Skin | FRP (glass fiber reinforced plastic) sheet. |

| Core | XPS (extruded polystyrene) foam. |

| PU (polyurethane) foam. | |

| Reinforcement materials | Composite material. |

| Waterproof wood. | |

| Accessories | Hinges (stainless steel). |

| Lock (stainless steel). | |

| Handle (stainless steel). | |

| Door frame (stainless steel). | |

| Door retainer (stainless steel). | |

| Rubber sealing strip. | |

| Application | Rear door. |

| Side door. |

High-quality materials improve the thermal insulation performance of the refrigerated truck door.

One of the key approaches to addressing vehicle door performance deficiencies is to select high-quality materials while simultaneously enhancing sealing and thermal insulation capabilities.

01. Insulated door panels: Low thermal conductivity materials

The door panel is a composite structure of “core material + outer skin.” An insulating core material with low thermal conductivity is selected while ensuring the weather resistance and strength of the outer skin.

- The insulating core material is XPS (extruded polystyrene) or PU (polyurethane) foam. PU foam has a lower thermal conductivity (approximately 0.022-0.025 W/(m·K)) and offers superior insulation performance. XPS foam offers superior moisture resistance and pressure resistance, making it suitable for transportation environments with high humidity.

- The outer skin is weather-resistant GRP/FRP (glass fiber reinforced plastic) sheeting. This material is lightweight and strong, effectively resistant to UV rays, rain, low temperatures, and other harsh environmental conditions.

02. Edge reinforcement: Double protection

- The edges of the door panels are wrapped with high-strength waterproof material, which not only prevents water vapor from penetrating into the interior of the door panels, but also improves the structural strength of the door panels. This design is crucial to the durability and thermal stability of refrigerated truck doors.

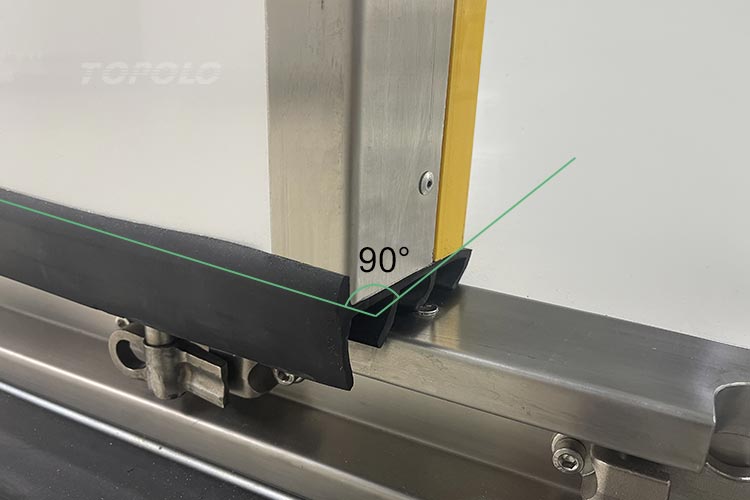

03. Door seals: Multi-tooth EPDM rubber

This combination of a “seal strip + sealant” creates a comprehensive sealing system, preventing heat and cold transfer through door gaps.

- The multi-tooth design increases the contact area between the seal strip and the door frame, enhancing sealing pressure and effectively preventing cold air leakage and hot air infiltration.

- The EPDM rubber also maintains excellent elasticity at temperatures down to -40°C, preventing hardening and cracking at low temperatures.

04. Stainless steel accessories: Enhance texture and durability

The door frame, handles, locks, hinges, and door retainers are all crafted from 304 stainless steel, either stamped or welded. They are corrosion-resistant, durable, and feature mirror or brushed finishes. These stainless steel accessories will not rust in environments with high salt, humidity, and pH. The service life far exceeds that of galvanized steel accessories.

Structural Optimization – Improving Door Operation Ease and Reliability

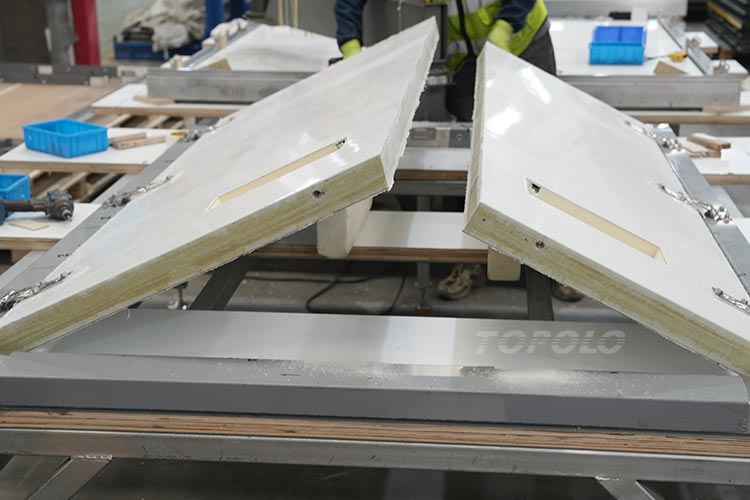

Pain Points of Traditional Right-Angled Doors

Traditional refrigerated truck doors often have right-angled edges, requiring simultaneous opening and closing of both doors. This creates significant friction when the right-angled edges meet, requiring operators to exert considerable force to complete the opening and closing motion. Furthermore, after prolonged use, if the doors become slightly deformed due to bumps or collisions, the right-angled edges can become stuck, preventing them from opening and closing properly.

Beveled Corner Design – Achieving “Easy Opening and Closing”

An asymmetrical beveled structure is employed, with differentiated design features on both sides of the door:

One door edge is designed with an “inward bevel” and the other with an “outward bevel,” creating a “staggered” fit. This eliminates the need for synchronized door opening and closing; operators can open and close one door independently before operating the other. The beveled design significantly reduces friction when the doors meet, allowing operators to open and close with standard force while avoiding the problem of jamming associated with right-angled structures.

Door Lock Design Styles

Two popular door lock options are available based on different usage scenarios.

The lock rod is installed outside the truck door to ensure the door remains securely locked when closed. It is typically used in conjunction with a heavy-duty padlock or deadbolt lock. This locking system is generally more durable, reliable, and affordable.

The lock rod is installed on the inside of the truck door panel, with the door handle recessed. They work in conjunction with the truck door’s hinge and locking system to further strengthen the door when closed and prevent interference from both inside and outside. This door locking system can improve safety and convenience.