Home » Sandwich Panels » Plywood Panel Series

Specification

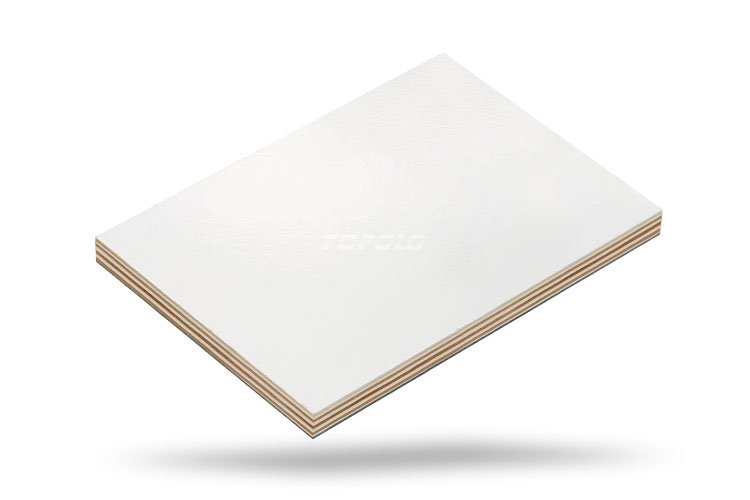

- Outer Facing: 2.0mm Quartz Sand Surface FRP Sheet.

- Inner Facing: 1.5mm Flat FRP Sheet.

- Core: Plywood. (Birch, pine, poplar, eucalyptus, oak, etc.)

- Composite Method: Adhesive.

- Thickness: 15mm. (Customized: 5.0-50mm)

- Length: ≤12000mm.

- Width: ≤3200mm.

DESCRIPTION

Features

- High load-bearing capacity

Its sturdy and durable structural design has a strong load-bearing capacity and can easily carry a single unit of several tons of heavy objects. It can still maintain structural integrity during frequent heavy object loading and unloading operations.

- Prevent sliding

The surface of the board uses a quartz sand GRP sheet with uniform particles. This ingenious design significantly improves the surface friction. During the driving process of the vehicle, it can not only effectively prevent the goods from sliding due to bumps, speed changes, etc., to ensure the integrity of the cargo transportation, but also provide reliable anti-skid protection for operators walking in the vehicle, greatly reducing the probability of slipping accidents.

- Not affected by chemicals

In a complex transportation environment, it is inevitable to encounter chemical leakage. The anti-skid GRP plywood composite panel has excellent chemical resistance. The leakage of various chemicals will not cause corrosive damage to the floor, ensuring the service life and performance stability of the floor.

- Long service life

The core material of the board is plywood that has been treated with waterproof and fireproof treatment. The waterproof treatment effectively prevents moisture penetration, avoids deformation and mold caused by moisture, and extends the service life of the floor. The fireproof treatment adds a “firewall” for transportation safety, reducing the safety risks caused by fire during transportation.

Structural Diagram

- Quartz sand particles (0.5-2mm in diameter) are embedded in the FRP surface to form a rough, non-slip surface. The rough surface of quartz sand significantly increases friction, effectively preventing slips and ensuring safe walking in harsh environments such as wet, oily, and icy conditions.

- The multi-layered, solid wood structure of the plywood base gives the board a high load-bearing capacity. Furthermore, as an economical wood material, plywood can significantly reduce the cost of floor construction.

Applicable application scenarios

- General Dry Freight Transport (Box Trucks/Dropside)

Prevents cartons, plastic pallets, and bagged goods (such as grain and feed) from sliding during transport, and also protects against foot traffic during loading and unloading (occasionally damp).

- Slippery/Leaky Freight Transport (Cold Chain Trucks, Fresh/Produce Trailers)

The quartz sand surface has a coefficient of friction ≥ 0.8, providing stable anti-slip performance even in wet conditions.

- Heavy/Industrial Freight Transport (Flatbed Trailers, Construction Equipment Trailers)

The quartz sand surface offers excellent abrasion resistance, preventing scratches when towing cargo, and its anti-slip properties prevent cargo from sliding during bumpy conditions.

- Trailers with frequent passenger traffic (such as rescue trailers and tool trailers)

The surface quartz sand particles provide anti-slip properties, while the toughness of the plywood base provides impact absorption, preventing cracking caused by dropped tools.