Home » Truck & Trailer Solutions » Truck & Trailer Kits

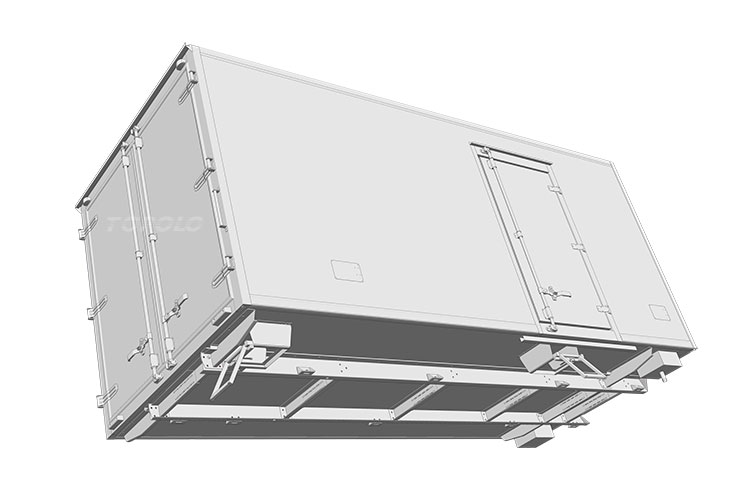

The subframe is the core connecting the chassis main frame and the refrigerator box. It not only bears the weight of the refrigerator box, but also absorbs the impact of road bumps. If the subframe of the refrigerated truck is not well fixed to the refrigerated box, the refrigerated box will easily move during sudden braking or bumpy conditions.

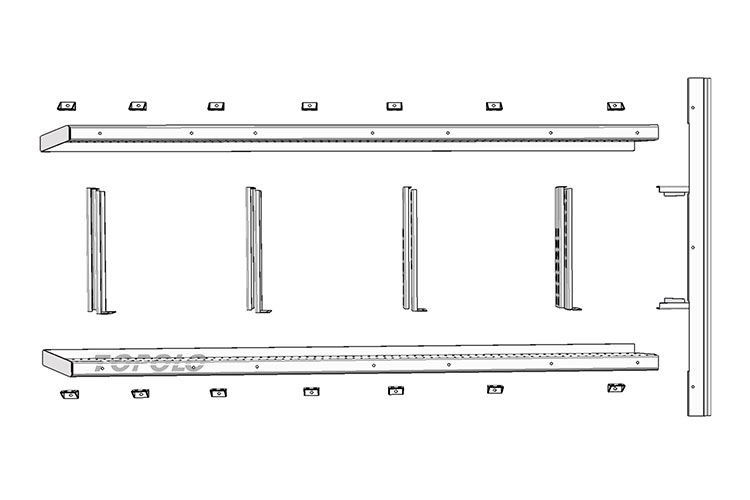

Specifications

| Components | Crossbeam, longitudinal beam, connecting plate, bolts, washers, nuts. |

| Material | Aluminum alloy, galvanized steel. |

| Length | 4.2m, 6.8m, 9.6m, etc. |

Refrigerated Truck Subframe Materials

Currently, the mainstream options are galvanized steel stamping and aluminum alloy extrusions. Each has its own advantages and suits different application requirements.

- Galvanized Steel Stamping: A Cost-Effective and Durable Choice

The subframe’s longitudinal and transverse beams are manufactured using a stamping process using hot-dip galvanized steel sheets (zinc layer thickness ≥ 80μm). The hot-dip galvanizing layer forms a dense zinc-iron alloy layer on the steel surface, effectively resisting corrosion from moisture, condensation, and road mud during cold chain transportation, preventing rust.

- Aluminum Alloy Structure: A Lightweight and Efficient Choice

Using 6061 or 5083 aluminum alloy for the subframe, it’s 40%-50% lighter than a galvanized steel subframe of the same size. Aluminum alloy naturally forms an oxide film (Al₂O₃) on its surface, protecting it from corrosion in high-humidity environments without the need for additional galvanizing. Its smooth, easy-to-clean surface prevents rust from causing joints to seize, minimizing maintenance costs (rust removal and maintenance are virtually unnecessary). However, aluminum alloy has lower tensile strength than galvanized steel.

Adjustable Structural Design

During the production and modification process of refrigerated trucks, chassis parameters such as wheelbase, crossmember spacing, and frame width vary significantly between different brands and models. To improve production efficiency and reduce costs, refrigerated truck bodies are typically produced using standardized dimensions (such as 4.2 meters, 6.8 meters, and 9.6 meters). If the subframe used a fixed structure, a new mold would need to be customized for each chassis, which not only increases production cycle time but also significantly increases manufacturing costs. The emergence of adjustable structural design allows for flexible adjustment of the spacing between the subframe crossmembers, achieving “one frame to adapt to multiple chassis.”