Home » Sandwich Panels » Honeycomb Panel Series

Specifications

- Thickness: 10-50mm or customized.

- Width: Up to 2.8m.

- Length: Up to 12m.

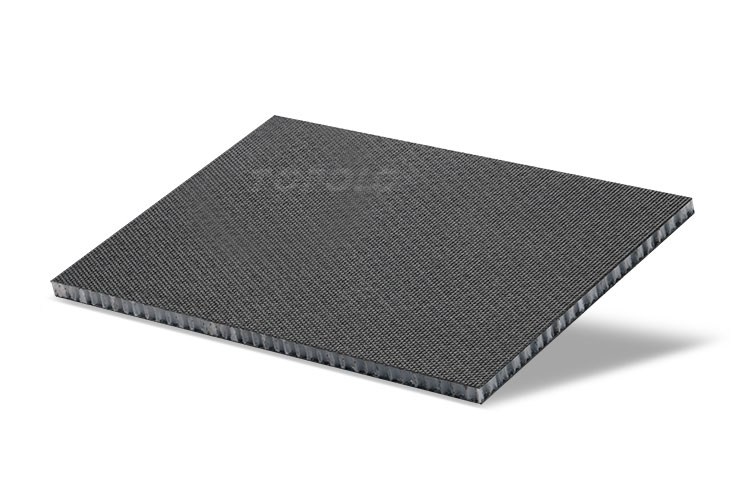

- Facing: Embossed CFRT (continuous fiber reinforced thermoplastic). (Thickness: 0.7-2.0mm)

- Core: Polypropylene (PP) honeycomb. (Density: 80-120kg/m³)

Description

Anti-slip thermoplastic honeycomb panels are increasingly used for dry freight truck floors due to their lightweight, durability, and superior performance in terms of safety and strength.

- Lightweight

Thermoplastic honeycomb sandwich panels are much lighter than wood floors, which reduces the weight of dry cargo trucks and improves fuel or power efficiency.

- High Strength

Continuous fiber reinforced thermoplastics have excellent compression and tensile properties. It is strong and very durable. It can withstand heavy objects without cracking or denting.

- Anti-slip

The surface of the honeycomb panel is usually treated with a special anti-slip treatment, which can effectively prevent slipping even if liquids and grease are attached to the surface.

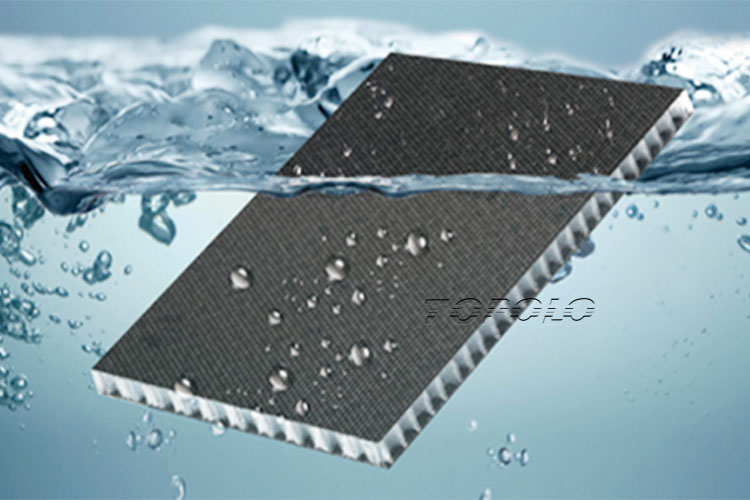

- Waterproof

Thermoplastic honeycomb panels are not hydrophilic, and they will not rust or rot. It allows the dry cargo truck body to be in close contact with moisture, even if rainwater seeps in or liquid leaks occur, it will not cause damage to the floor.

- Recyclable and efficient utilization

Thermoplastic honeycomb panels are not only durable but also recyclable, making them an environmentally friendly choice. Usually, thermoplastic honeycomb panels are double-sided non-slip, and the other side can be used after the service life of one side expires.

Installation Description

- A whole piece of non-slip honeycomb panel is easily installed on the subframe as part of the body.

- The edges of the floor are fixed with rivets, and the center does not need to be fixed again, which will not affect the integrity of the floor.